#PeopleBehindTheBrand Emmanuel Pseftoudis

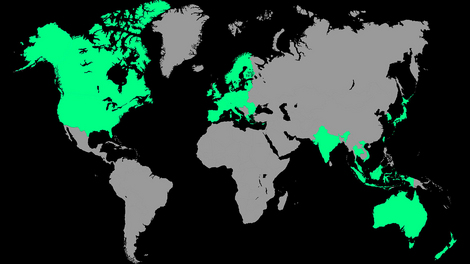

20 years of HOMAG Australia – As part of the globalization of the HOMAG Group and the expansion of its reach from the manufacture of the machine to the direct relationship with the end user, the company HOMAG Australia was founded. This gives Australian manufacturers easy access to the HOMAG world and its solutions – all from one source. #TogetherForYourSolution our employees work with ambition and full of energy day in, day out. To get to know the people behind HOMAG Australia, we spoke with one of them.

For this interview, we spoke with Emmanuel Pseftoudis. Emmanuel already worked at HOMAG Australia from 2003 to 2010. In 2020, he found his way back and has now been working for HOMAG Australia again as technical sales consultant.

HOMAG Australia is now looking back on a 20-year success-story. How did Australian woodworking industry develop in this timespan?

Emmanuel Pseftoudis: The woodworking industry developed from panel saw and iron and manufacturing by hand now developing into automation and producing product more cost effective and less labour intensive.

What will be the main challenges in the Australian woodworking industry in the next years and which solutions does HOMAG Australia offer to help customers mastering them successfully?

Emmanuel Pseftoudis: Skilled labour shortages, needing machinery and digital solutions to help customers improve their output without the need of skilled workforce. HOMAG is always looking ahead to see what solutions can help the customer.

What are HOMAG Australia´s core products – its daily business in term of machines?

Emmanuel Pseftoudis: Edgebanders and Cnc’s are HOMAGS core products that are needed in Australian manufacturing from day to day. Shortage of Staff is creating a market for even smaller customers to embrace the nesting and egdebanding machines to make the customer more effective to produce a high-quality product. Customers also benefits from quick turnaround times for the product and less waste.

How important is digitalization in Australia and thus the digital products of the HOMAG Group?

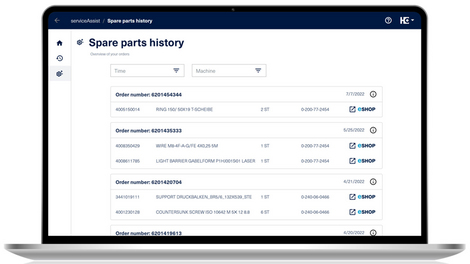

Emmanuel Pseftoudis: We are at early stages here in Australia in regard to Digitalization this will improve in time with demand. For me, digitalization means faster response time when machine breaks down, or offering solution on how to fix the problem yourself creating less down time. Tool maintenance will be monitored, which in turn leads to less downtime and inferior products, saving money and time and extending the life of the tools.

What are your expectations for HOMAG Australia in the next five years?

Emmanuel Pseftoudis: New products in regard to Edgebanders and CNC’s to make them more competitive in the market and new solutions.

What are your personal highlights in your time with HOMAG Australia?

Emmanuel Pseftoudis: Highlights are that I have developed a strong customer base with my product knowledge and industry knowledge over 20 years now in the industry. I listen to the customer and always will offer the right solution suited for their business, not just sell a machine for the purpose of selling a machine. That entail brings me repeat customers and word of mouth new customers offering the right solution.

Thank you, Emmanuel, for the exciting impressions. We are already looking forward to the next interview of our #PeopleBehindTheBrand story – stay curious!