INDIAWOOD 2022: Hall 4 | All from one source | HOMAG India

From 2nd – 6th June 2022 HOMAG India will be providing interesting news about machines, software- and service solutions for woodworking at the INDIAWOOD 2022 – all live-in action. Discover YOUR SOLUTION through HOMAG India's holistic approach to modern market requirement and trends. Numerous HOMAG India experts from Sales, Technology and Service are looking forward to speaking with visitors and will be on site to answer any questions in Hall 4, Booth No. H4120.

We are looking ahead forward: Among other things, HOMAG India will be presenting solutions for edge banding, panel dividing and CNC-operating. Visitors will also get to know how they can use digital assistants from HOMAG to increase performance and efficiency while ensuring sustainability at the same time. And that's not all. There will also be news in the Service area this INDIAWOOD – the new “APAC Hotline”. In short: professional services in your time zone.

Step by step: Success with individual components

Shaped parts and straight edges EDGETEQ T-200 – the “one for all jobs”

The EDGETEQ T-200 is not only a machine, but also represents a flexible machine not only for efficiently and reliably gluing a series of formed parts but also processing smaller quantities of straight parts. The EDGETEQ T-200 has a gluing system, which applies the glue directly on to the edge banding material. The coil-cut off device is either activated by foot pedal, or, for serial production, by pre-selecting the edge length via digital length counter. The panel is placed on heightened spacers, which are fixed on the working table, according to the shape of the panel, which requires no template Because of the flexibility of in the EDGETEQ T-200, shaped parts and straight parts can be processed easily on this machine.

EDGETEQ S-230 Series, NKR 210 and NKR 220 - Both a perfect starting point.

Edge Banding Machines offer perfect edges for discerning wood manufacturers for panels of all sizes. HOMAG provides first-class edge processing solutions for a wide range of processes and materials with extreme accuracy and precision. Whether your needs are “batch size one” production, for demanding bespoke shop fitting applications, or living & bedroom furniture or functional office furniture, the EDGETEQ always offers the right solution for your requirements. The EDGETEQ S-200 - NKR 210 and EDGETEQ S230 - NKR220 machine leaves nothing lacking. Booth are equipped with a precision gluing unit, a tiltable end trimming unit for straight and chamfer trimming and a top/bottom trimming unit. The feed speed of these models is 11 m/min. For complete processing options and a perfect finish, add a joint trimming unit, a contour trimming unit, a radius scraper, a glue joint scraper or a buffing unit. The EDGETEQ S-230 Series always offers the right solution for all your requirements.

The Sliding Table Saw – Perfect solution in every workshop.

A sliding table saw has a very central position in workshops. It is still Compact in size, ergonomic in operation and equipped with a sharp saw blade, the K32 is made for the demands of aspiring craftsmen. As one of the most important standard machines, it is an indispensable tool in any workshop that works with full panels and boards of any standard available sizes. The sliding table saw K32 can be perfectly adapted to the requirements of every workshop.

The important highlights of sliding table panel saw K32

- High quality, Extruded Alloyed Aluminium profile sliding table. Liberally ribbed & anodized for long life of the table.

- Hardened & ground round guide rods.

- Hardened & precision ground prismatic V rollers for smooth stick slip free table movement.

- Graded cast iron saw carriage. Liberally ribbed for high rigidity & sturdiness.

- Hardened &ground round guideways for saw spindle vertical adjustment. Extra wide segmented guide for tilting feature -45°.

Panel Dividing Saw SAWTEQ B-100

Top quality at the best possible price: the smallest saw in the HOMAG range is equipped with everything you need for panels and small batches. The SAWTEQ B-100 panel saw costs hardly any more than a well-equipped sliding table saw, while providing a much more precise and efficient cutting process. This is achieved by proven HOMAG technologies. In short, the SAWTEQ B-100 panel-sizing saw makes it easier than ever for you to ease your way into the world of precision manufacturing.

As standard, HOMAG equips the panel dividing saw with everything you need for high precision cutting of single panels and small series. This saves you having to evaluate various technical solutions and you can start using your new HOMAG machine straight away.

As option, HOMAG offers the Cutting Production Set: The Cutting Assistant. Which means Cutting optimization & label printing for SAWTEQ B-100.

Our cutting assistant supports you in optimizing your cutting patterns, in labelling the parts and in the cutting process on your manual saw. Simply optimize your cutting patterns with a click and transfer them to the app on your tablet in the workshop. Here, you work through the cutting pattern with the help of a clear display in the app – and print an individual label for each part. This way, each workpiece has all the info for subsequent processing.

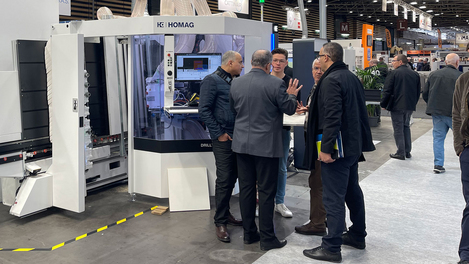

Dowel Hole Drilling Machine DRILLTEQ C-100

Model NBS 033 and Model NBS 090 - The easiest way for perfect dowel hole drilling

Dowel drilling machine DRILLTEQ C-100 – NBS 033 are used to drill dimensionally accurate holes on panels, into which the dowels – the round, threadless, wooded pegs used for wood construction – are to be inserted. As individual machine the DRILLTEQ C-100 – NBS 033 has one task: dowel hole drilling – making the machine simply more efficient and reliable.

The highlights of this model:

- Robust steel fabricated & precisely machined table & tilting unit

- Highly precise drill block with 21 spindles

- User-friendly quick-change collet system

- Pneumatic cylinder ø100X100 mm stroke drill feed

- Extended fence 3000 mm with bi-directional flip stoppers

- Adjustable clamping bridge with 2 pneumatic clamps

DRILLTQ C-100 – NBS 090 is an universal dowel drilling machine with a long range of equipment and has two tasks: drilling and dowelling with perfection.

The highlights of this model:

- Solid machine frame with 2 beam designs

- Twin LM guide system for longitudinal traverse of vertical drill heads

- Highly precise drill blocks with 21 spindles

- Quick change collets system

- Continuous 32 mm pitch (also between the drilling blocks)

- Quick swivelling vertical drilling blocks, fixing at: 0° - 90°

- Large working area with extended scale

Our dowel hole drilling machine models are space saving products for clever support in your company.

Service - APAC Hotline

With our globally established service network, we as the HOMAG Group support our customers with excellently trained specialists - professionally and reliably. At INDIAWOOD, we will be presenting the new APAC hotline to our customers for the first time. The special thing about the new service solution: In the past, our customers from India used to contact the German hotline when they had complex questions about the machine or the software and had to put up with the time difference between India and Germany. Now, with the APAC Hotline, there is no longer a big-time difference. The new APAC hotline with its team of specialists can answer the inquiries of our Indian customers in their own time zone.

Moreover, no matter where our customers are located, they only need to contact our hotline if they need further support to solve complex problems with the machine or the software.