HOMAG Treff 2022 in Holzbronn: Together again

A packed exhibition hall and enthusiastic visitors. At this year's HOMAG Treff, visitors were able to experience solutions live. For 30 years, HOMAG has been using the in-house trade fair to present innovative, state-of-the-art solutions for both woodworking shops and industry-level production to its customers and interested parties. The HOMAG Treff took place at the Holzbronn site. HOMAG can look back on five successful days at the trade fair.

More than 1000 visitors from more than 40 countries attended the HOMAG Treff. In addition to factory visits, the participants were impressed by the highly complex machine technology and found out about the latest products during exciting machine demonstrations. But there was also ample opportunity to exchange ideas and information with others during the trade fair program. Attendees were able to discuss questions and concerns directly with the HOMAG experts. Further valuable information on various topics was given in various technical presentations.

The right solution for every requirement

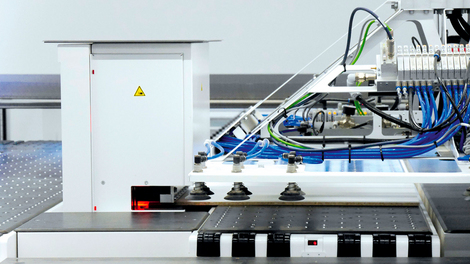

The focus of the trade fair was on HOMAG's comprehensive product portfolio, which clearly demonstrated how much potential there is in every modern workshop. Over an area of more than 2000 m 2, the company presented solutions for efficient production that enable both automated furniture production and the production of individual components. HOMAG doesn't rely on machines and plants alone. By using apps and digital assistants to organize production digitally, obstacles in everyday working life can be easily avoided and the service offering increases the performance and service life of the machines.

Among the highlights was the DRILLTEQ V-310 vertical CNC processing center. The space-saving masterpiece allows the largest range of functions in the smallest possible space at only 11 m 2. In addition to optimum cabinet processing, the processing center offers numerous processing options with its selection of up to 45 drilling spindles.

The new Nesting CENTATEQ N-510 CNC gantry processing center also shines when it comes to performance. The new nesting concept offers individual automation with five-axis processing for the entry-level woodworking shops up to industrial requirements. Panel-shaped materials can thus be divided and processed with optimized waste levels. Therefore, the focus of the new nesting series was intentionally on improving handling and increasing output.

HOMAG presented the production simulation on the Panel Dividing Machines SAWTEQ B-300 | B-400 flexTec for the first time. This simulation is based on companies' own parts lists and customers' current production data and shows what everyday life in production could look like with the SAWTEQ solution. The production preview is optimized for automatic cutting or for maximum performance. This means that HOMAG is creating transparency about production times, including possible ghost shifts, the necessary operator times, the part output per shift and the stacks created.

Solutions for the digital future

The interest in digital solutions for wood processing was evident at the HOMAG Treff. But what do tomorrow's digital woodworking shops look like? Here too, HOMAG presented efficient and innovative solutions to its visitors. In addition to the digital job folder, the productionManager and the new woodCommander 5 operator software with 3D workpiece simulation, the Nesting Production Set was also presented. The applications included in the set enable automated calculation of nesting patterns and identification of components by labels, even if no printer is available on the machine. Another advantage: the Nesting Production Set can be used flexibly in conjunction with nesting machines of any series.

HOMAG Service as a production partner

Supporting customers and continuously strengthening their processes: This is the HOMAG Services approach. Generating additional value for customers is the top priority here. For this reason, visitors to the HOMAG Treff had the opportunity to take part in the trade fair offer for the App-Plus Package and to test it for 12 months free of charge. The App-Plus Package offers customers the ideal entry into the world of HOMAG's digital products and includes five apps: MachineBoard, MMR mobile, Serviceboard, ServiceAssist and twinio.

Coming together and exchanging information and ideas

As has already been shown in recent months, personal contacts and face-to-face discussions are essential. Intensive consultation took place at various meeting points over the days of the trade fair. HOMAG is already looking forward to the next big live event: The WEINMANN Treff will take place on November 16 and 17, 2022 in St. Johann-Lonsingen. Once again, there will be the opportunity to exchange ideas and information in person.