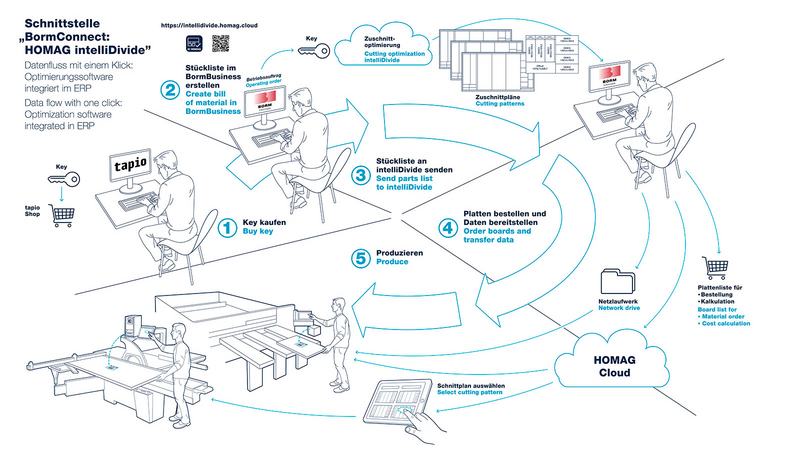

Data flow with one click: Optimization software integrated into ERP

New interface between BormBusiness and HOMAG digital solutions

How do I transfer the data for my job from the ERP system to the cutting optimization software? How can I calculate how much material I need for each order more accurately and more quickly? And how can I do all this as fast as possible?

Together with BORM-INFORMATIK AG, HOMAG is providing the answers. Using a common interface, the two companies are demonstrating how simple and straightforward it can be for companies in the wood-processing industry to seamlessly exchange data between different systems.

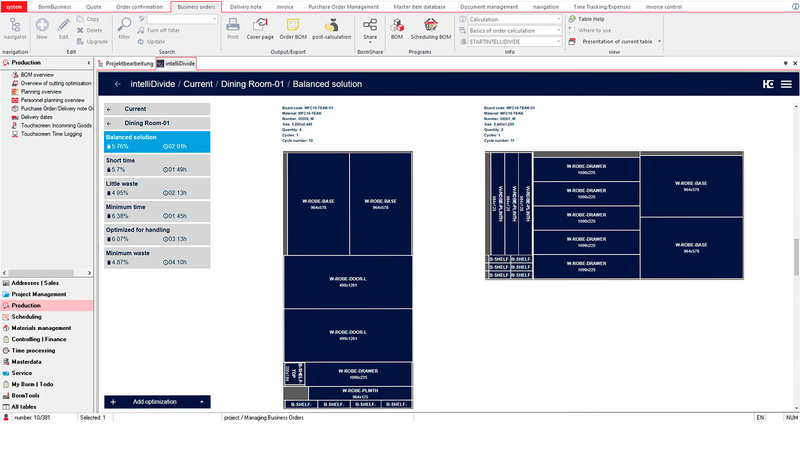

The new "BormConnect: HOMAG intelliDivide" interface connects BormBusiness' ERP with HOMAG's digital solutions — in this case with "intelliDivide" cutting optimization. From now on, whenever data is exchanged between the different manufacturers' software solutions fully automatically in the background, users will see a uniform and lean solution from a single source.

Optimized cutting patterns and exact calculation of material required

With a single click, employees can easily transfer parts from the Borm parts list to the "intelliDivide" optimization software. This software is then used to directly start cutting pattern optimization for the corresponding job. The information about the materials used is stored in the BormBusiness product database (panel type, dimensions, grain, etc.) and supplied at the same time. Following optimization, "intelliDivide" immediately provides information about the materials required or the precise quantity of panel material needed for the job. Using the information supplied by the optimization software, employees can now order precisely the quantity of material that is actually needed for the job. This means that no unnecessary material is ordered, thus saving money.

Once optimization is complete, the user sends the final cutting patterns to a HOMAG panel dividing saw or from the HOMAG "Cutting Production Set" tool to a manual saw provided by any manufacturer.

Simple data exchange provided via tapio

A straightforward process, seamless data flow and clean handover — all without users having to contact individual software providers for time-consuming and therefore expensive coordination. The only thing users need to do is to subscribe to the "BormConnect: HOMAG intelliDivide" interface on shop.tapio.one. The interface subscription can be set up on a monthly or yearly basis, meaning it can be used as needed. When the user logs in to their tapio account, they can copy a unique access code for the interface and save it in BormBusiness — and that's it, data will be seamlessly exchanged between the two software solutions. There is no need to coordinate with software providers or configure the interface.