There's more to come ...

Norbert Bosch (49) is someone with an edge, someone who thinks outside the box, someone whose trade is his passion — and his life. In 2002, he took over the business founded by his father Walter in 1954. The company, Walter Bosch, specializes in interior fittings and complete furnishings for banks, offices, shops and hotels, as well as high-quality furniture and interior fittings for the private sector. The two most important pillars of the production specialist, located in Rühlingstetten in the Middle Franconia region of Germany, are furnishings for hotels and other commercial properties and the production of parts for the furniture industry, as well as for colleagues from the joinery trade.

Batch size 1 technology meets service

With a view to the joinery trade in particular, the head of the business, which currently has 30 employees, succinctly sums up the supply competence of his business: "We can produce finished furniture parts from batch size 1. Minimum quantities? We don't have those. In contrast to the furniture industry, the wood trade needs individual single pieces rather than serial parts in large quantities. Other joiners can order finished furniture parts from us that are freely defined and tailored to their own designs and fittings."

That's a clear statement: nothing is impossible. In addition to the pure technical (production) capabilities, in this business, reliability, adherence to delivery deadlines, flexibility and, of course, excellent service stand alongside high quality.

It appears that Norbert Bosch and his team have mastered all of these disciplines very well. They have extended their business into the neighboring countries of Austria, Switzerland, France and Holland. And the company has also already delivered parts to the USA. As an example of the company's power, Walter Bosch can produce finished, veneered and painted parts within four hours of an order.

Modern machines and more

However, you can't make something out of nothing, meaning that behind the many opportunities and promises to customers as detailed, there is a well-thought out and high-performance infrastructure. State-of-the-art machines, as can be found in the generous production facilities, are not enough on their own to achieve this. However, they are, of course, a prerequisite for efficient production at this constantly high level of quality.

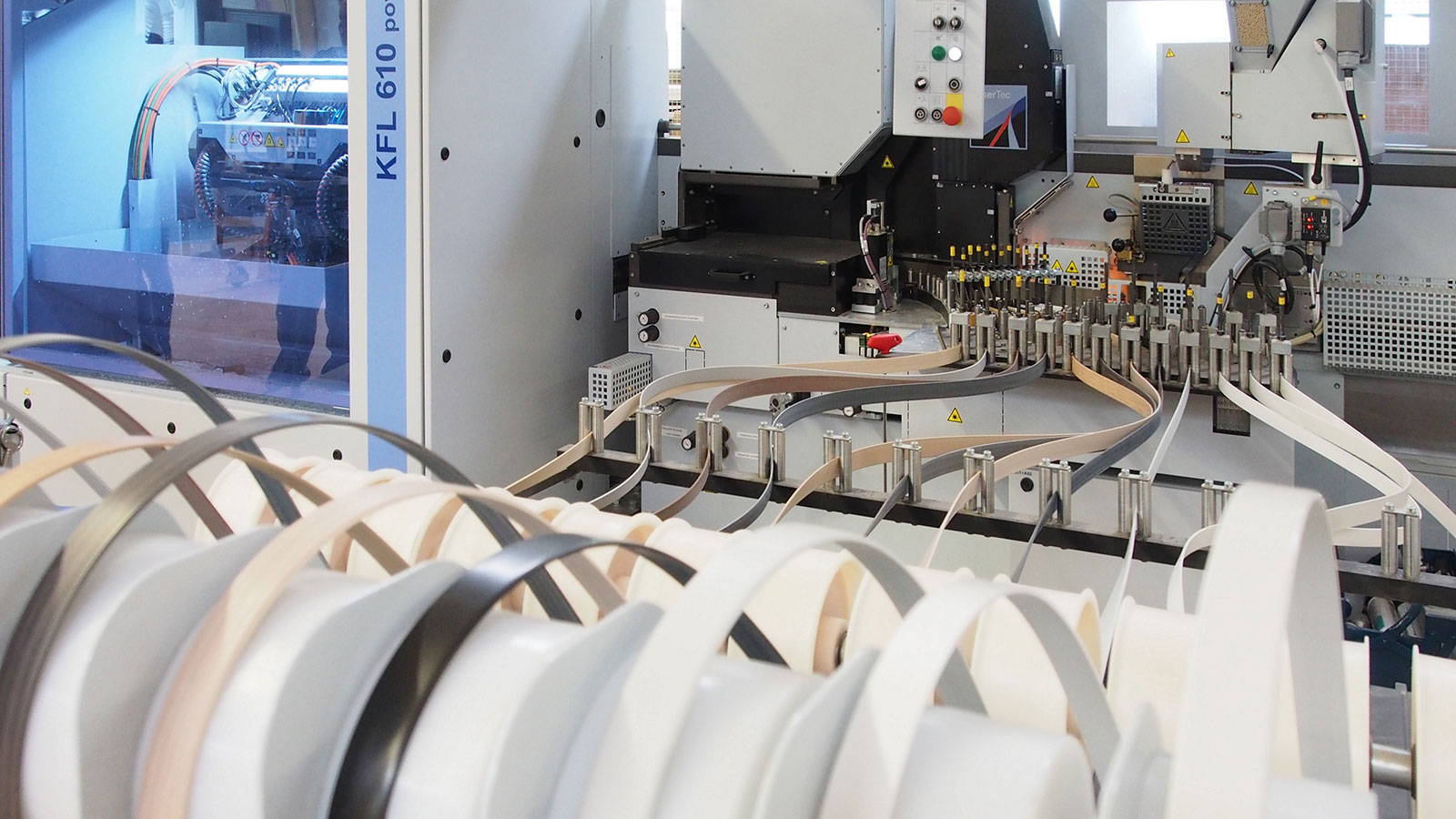

Perfect edge processing

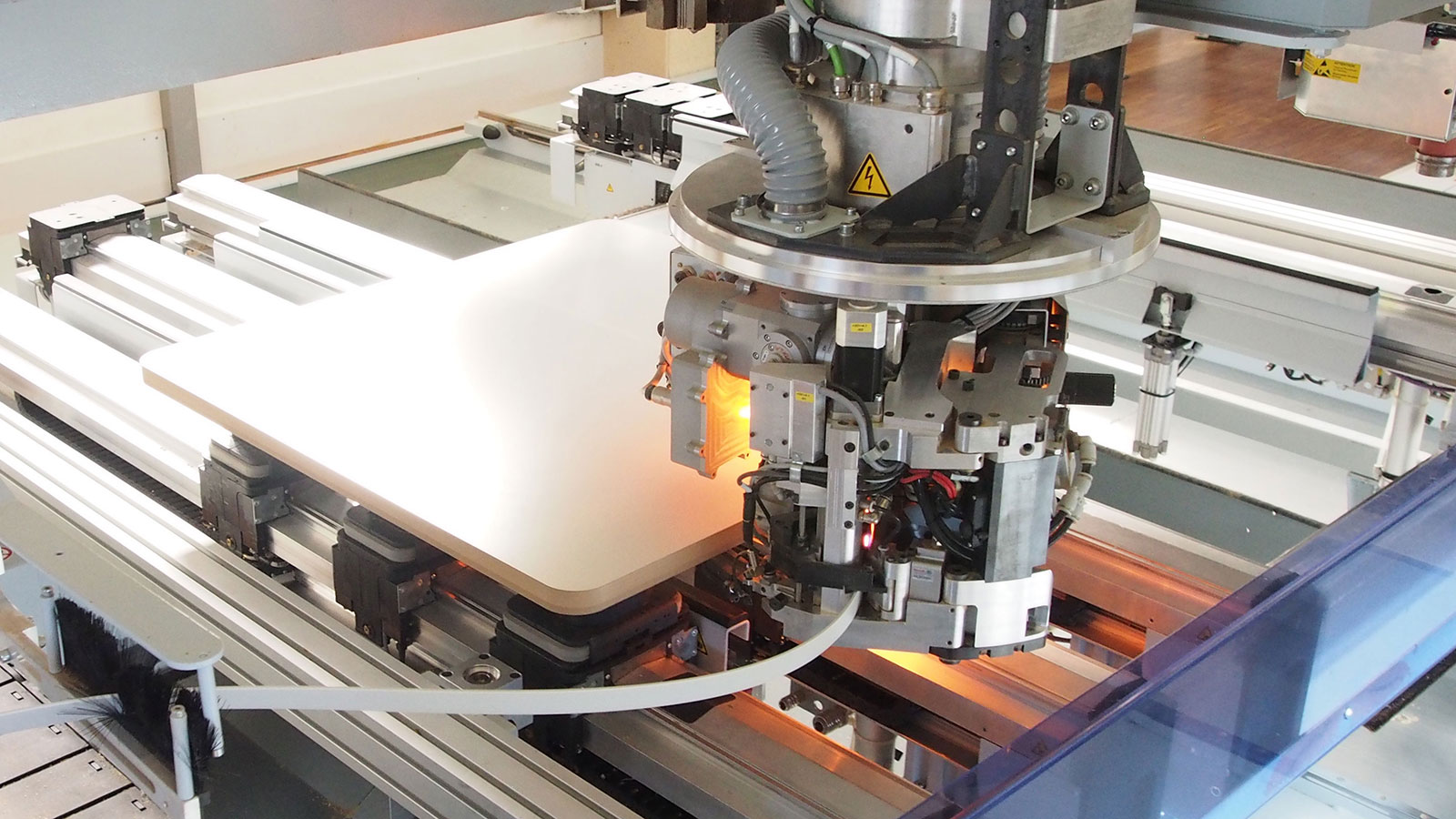

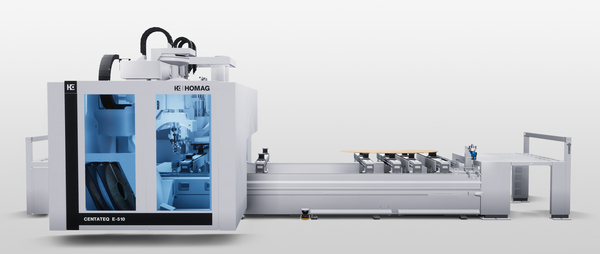

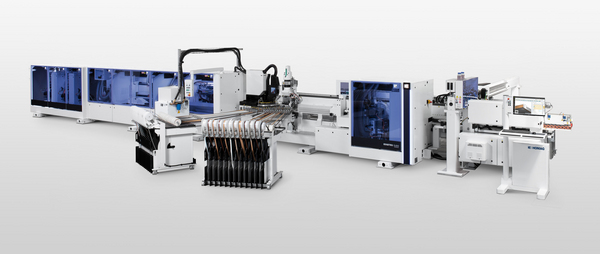

Norbert Bosch is a self-confessed HOMAG fan. Almost all of the machines and plants in his production facilities bear the logo of the global market leader, including the brand-new KFL 610 powerLine edge processing system. The KFL 610 powerLine is equipped with both a laserTec unit and a hot-melt glue unit and has been consistently tailored for batch size 1: a wide variety of parts pass through the machine in no particular order and are automatically provided with the correct edge material and subjected to the respective individual processing required.

The change from laser processing to processing with hot-melt glue and vice versa also takes place in a flash from one part to another without the operator having to intervene in any way. The system knows precisely how each individual part is to be processed and is operated by just one employee. At the rear end of the machine, a robot either transfers the parts to the part return for further edge processing or stacks the finished parts.

But how do the machine and the robot (and, of course, all the other machines and the employees at the manual workstations) know at any point in time how any individual part is to be processed? Who gives them this information? This is where a component comes into play without which, such automated processes would not even be possible.

The brain behind automated production

Within the framework of digitalization, machines and processes can no longer be considered in isolation. As well as investing in the edge processing system, Norbert Bosch has invested in the ControllerMES production control system from HOMAG. It is this control system that enables design and parts list data to be prepared in such a way that all subsequent — in some cases automated — processes on machines and manual workstations can be optimized and organized individually. From the intelligent configuration of the production data, through production planning, right up to the completeness check after final assembly, the modular system maps all areas.

Norbert Bosch saw ControllerMES for the first time at LIGNA 2017. He explains what he wanted: "I didn't want a third-party provider. I just wanted a system partner that could offer me everything from one single source. I relied blindly on the HOMAG experts." In our discussion he is very satisfied with the way things turned out: "Controller MES is the first software that has impressed me from the very first second."

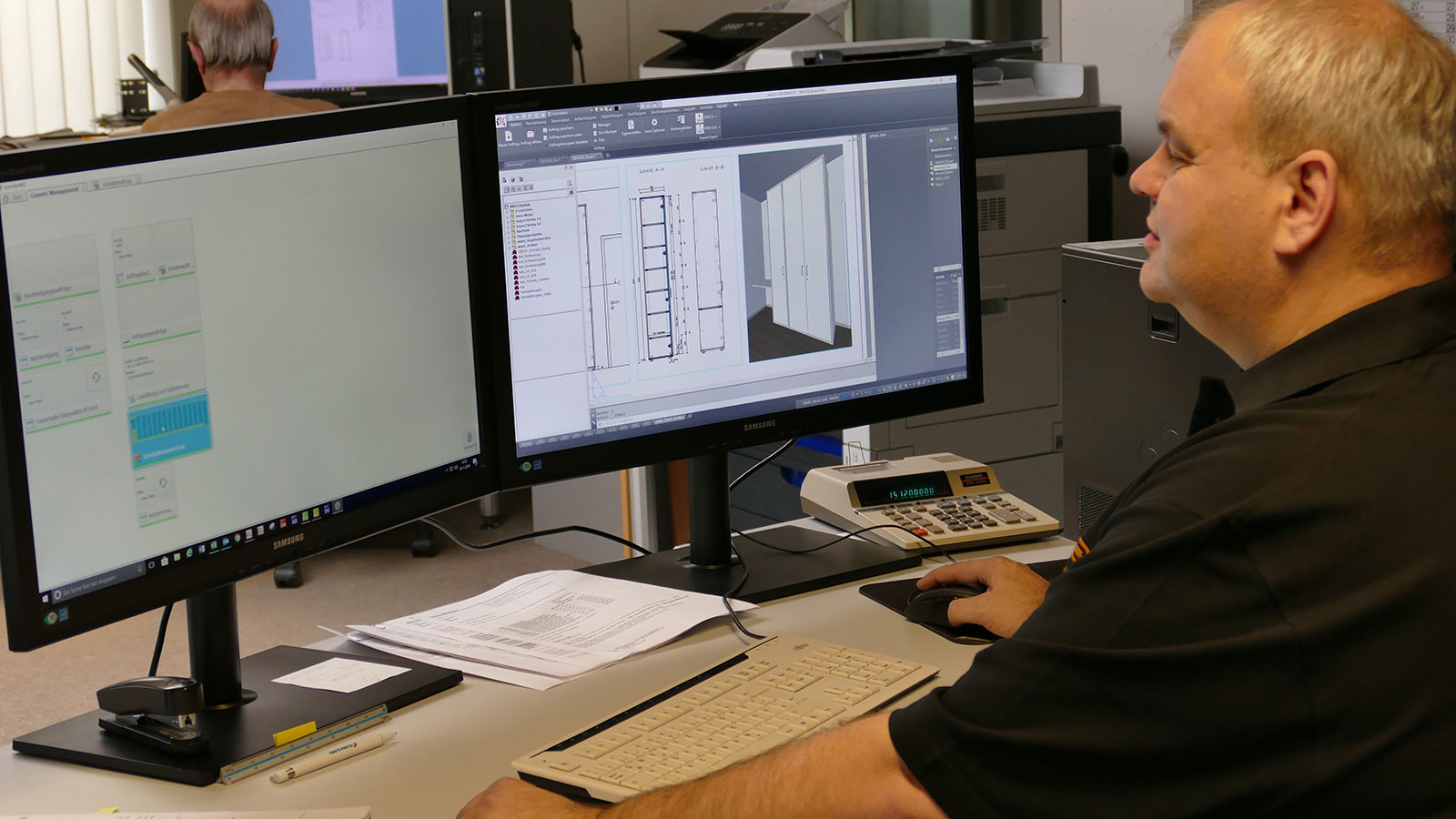

Industry software and CAD as a basis

Since 1985, Norbert Bosch has been using the industry software from OS Datensysteme (OSD). He has been using the CAD system Imos since 2004, currently the new version Imos iX. With regard to work preparation, the orders go one of two ways: standard parts (e.g. cabinets with variable dimensions, conference tables in standard sizes, etc.) are processed solely using OSD. In contrast, parts with very individual requirements are designed with Imos iX. Once the planning for an order is finished, the data is then sent to ControllerMES. At present, around 95% of the data at Walter Bosch come from OSD, with the rest coming from Imos iX.

A real quantum leap

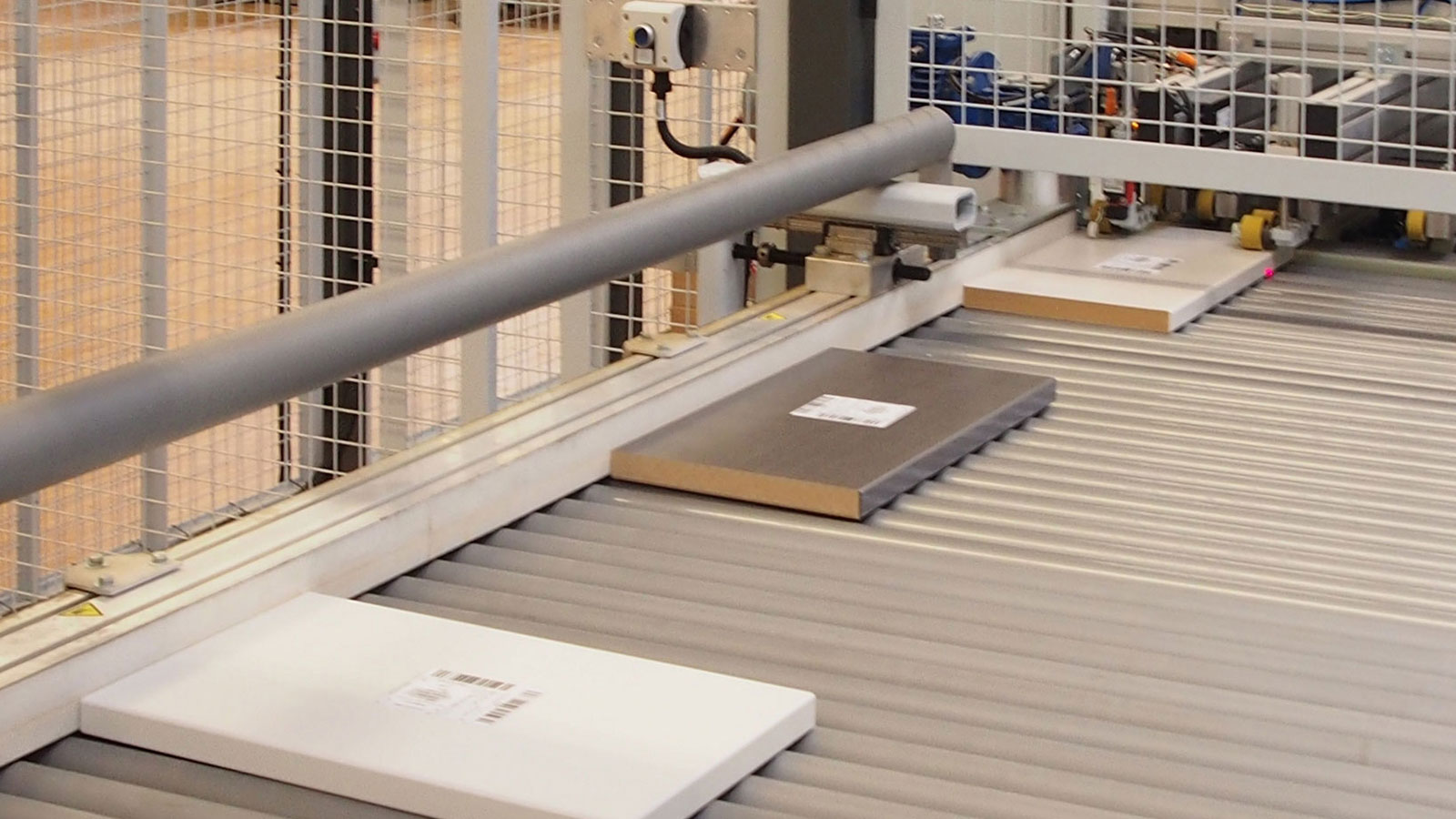

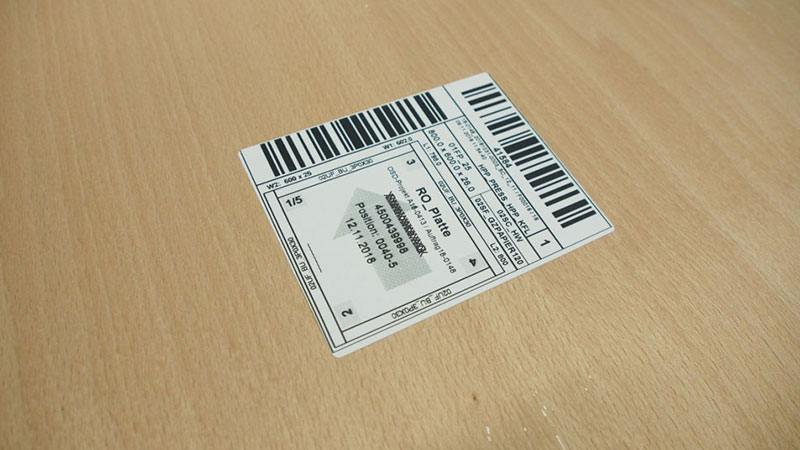

This is where intelligent data handling in ControllerMES comes into play. The production control system provides the cutting optimization with data, generates the data records required for label printing and edge and CNC processing, and assigns unique component numbers, referred to as unique part IDs. The automated edge processing, for example, can only take place once this information is available. The data for aligning the veneers and for printing the associated labels is also generated.

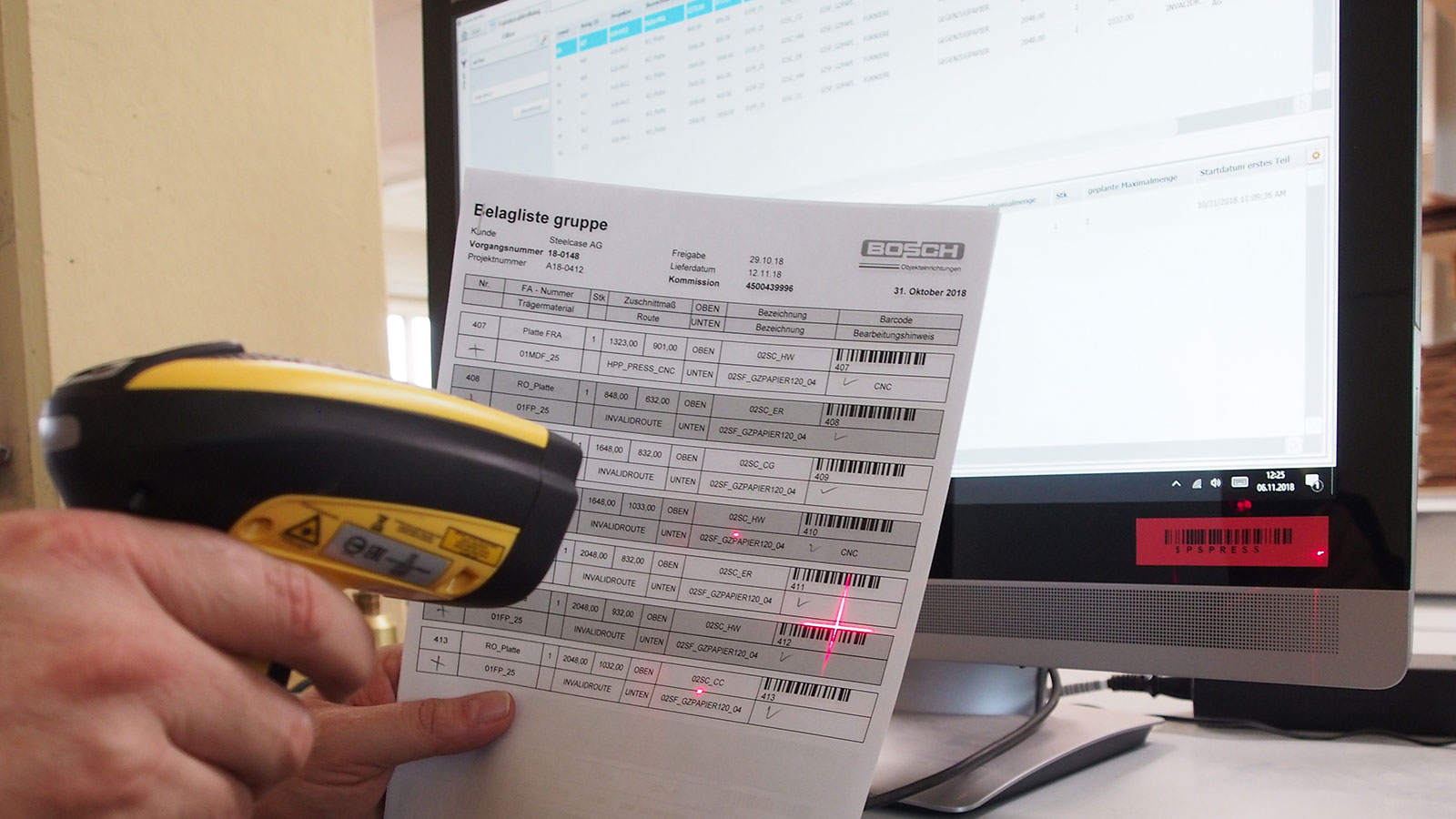

On the two CNC processing centers, the scan of the part labels starts the corresponding processing immediately. And at the manual workstations, the production control system provides, precisely and in graphic form, only that information that is actually needed there.

When you consider that just six months ago, at Walter Bosch, parts data was entered in Excel manually and then the spreadsheets given to production, the latest investments are a real quantum leap.

A highly flexible future

With the investments in machine technology and the production control system, Norbert Bosch feels he is well equipped for the future. He has significantly increased capacity, quality and economic efficiency. He has also gone the extra mile with regard to flexibility.

This agile master joiner has achieved a lot but there is still a lot he wants to do: "Standing still actually means going backwards, and we always look to the future. We already have the next concrete projects in mind. Let's see what our own ideas and the inventive spirit of HOMAG can produce. I'm sure there's more to come..."

Brief portrait of ControllerMES: Integrated data and information flow

ControllerMES is the production control system from the HOMAG Group. It enables an integrated information flow within production and at the same time, offers high-quality digitalized production planning and organization. In the first step, the data is generated in an ERP and/or CAD system, then transferred to ControllerMES, where it is organized and prepared intelligently for all further processing and processes.

Labels with barcodes enable each component to be identified uniquely — regardless of where it is in the production process. And through the barcode being read, the machine data required is provided to the respective machine (e.g. cutting, edge processing, CNC). Waste is reduced, thanks to the flexible grouping of orders when batches are formed and the seamless communication with the Cut Rite cutting optimization.

The progress of the orders can be viewed in ControllerMES throughout the entire production process. At a glance, you can see whether the individual components are ready for assembly or can be delivered. And if a part has to be reproduced, ControllerMES supports this with a corresponding predefined logic.

An article by the magazine BM, 08/2018. Photos : Magazine BM / Christian Närdemann. BM Online

“Controller MES is the first software that has impressed me from the very first second.”Norbert Bosch, Walter Bosch GmbH

More about Walter Bosch GmbH

In 2002, Norbert Bosch took over the business founded by his father Walter in 1954. The company, Walter Bosch, specializes in interior fittings and complete furnishings for banks, offices, shops and hotels, as well as high-quality furniture and interior fittings for the private sector.

The two most important pillars of the production specialist, located in Rühlingstetten in the Middle Franconia region of Germany, are furnishings for hotels and other commercial properties and the production of parts for the furniture industry, as well as for colleagues from the joinery trade.

www.wabo.de