An article from the specialist magazine Bauen mit Holz, 09/ 2016, www.bauenmitholz.de.

According to the company, the energy-efficient shell and a high-quality building technology concept mean that the "vital office" requires 50% less energy than current energy-saving regulations demand. Another highlight is the "silent ceiling", for which Regnauer was awarded the Bundesinnovationspreis (German prize for innovation) in 2011. This ceiling is installed throughout the building. The construction of the "silent ceiling" impresses with an upper surface, a support system and a lower surface that is suspended using a special vibration absorber, ensuring maximum noise protection performance. This offers employees optimum acoustic conditions in the offices and conference rooms.

New production system optimizes processes

To manufacture these products, especially the "silent ceiling", Regnauer invested in a new WEINMANN CNC production system for fabricating roofs and ceilings in 2015. "In order to efficiently manufacture the newly developed products, it was necessary to adjust the processes and techniques," says Markus Leppin, who is responsible for technology at Regnauer. "Furthermore, we did not want to miss out on the significant advances that have been made in machine and control technology in recent years."

The innovative powerTouch operating system in particular has significantly simplified the working process. The entire programming interface is optimized for touch operation and offers numerous new help and assistant functions that make working processes substantially easier.

When planning the new production system, the main focuses were the machine technology on the one hand, and the handling systems and insulating technologies on the other. In addition, it was important to develop a comprehensive process that would take material manipulation, logistics and material flows into consideration, as well as the interaction between the various systems. To achieve this, Regnauer sought a provider that is able to deliver process optimization alongside machine technology. Due to the high quality of the machines and the professional specialist consultation, WEINMANN was chosen to provide a roof and ceiling production line. The performance requirements and the challenges in manufacturing the "silent ceiling" played the largest role in the decision. The bespoke concept for Regnauer was developed on this basis.

Highly flexible plant enables manufacture of different products

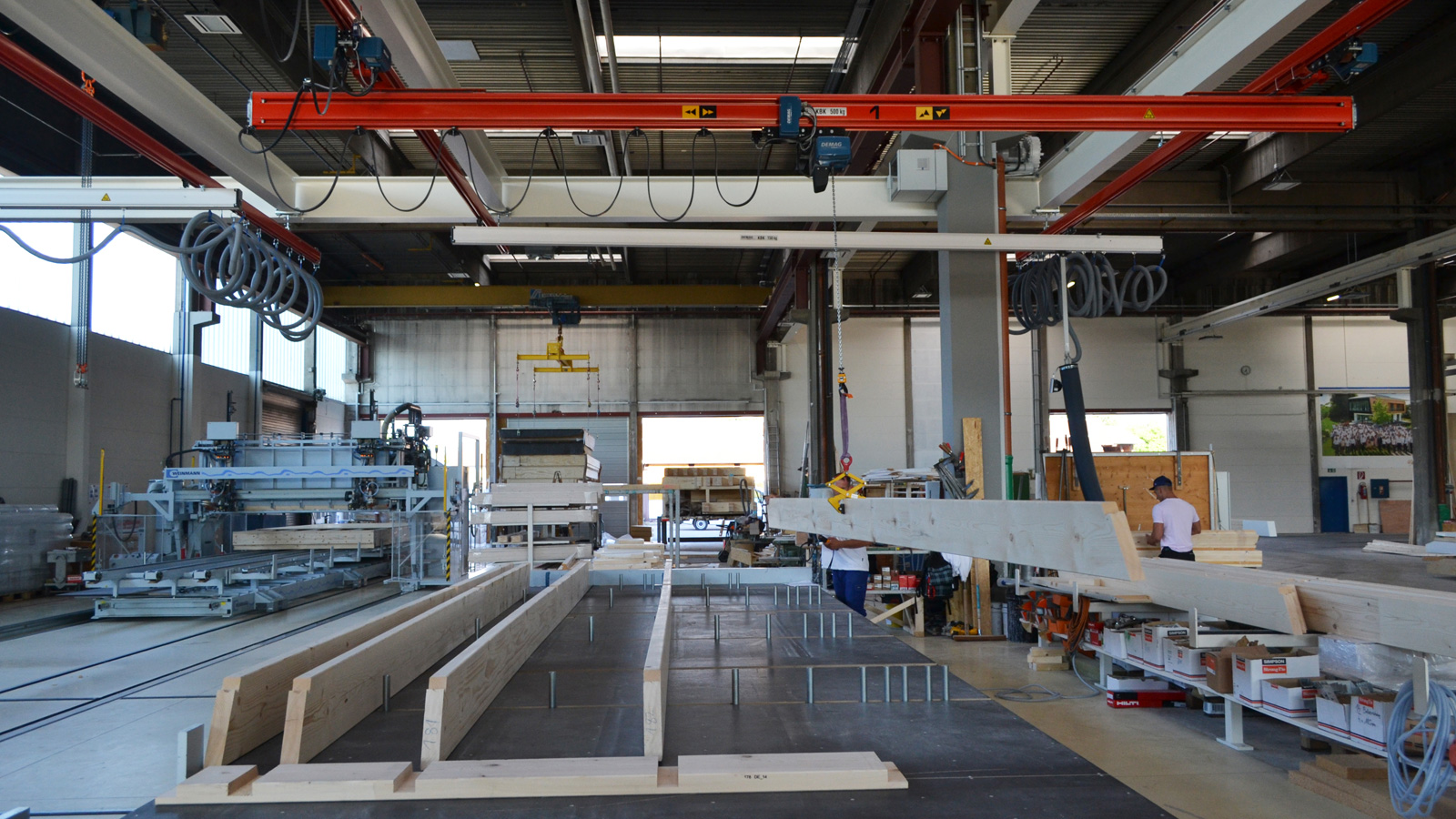

The roof and ceiling production line consists of two insertion tables, two downstream work tables and a multifunction bridge. With the NC-controlled insertion tables, the positions of the rafters and beam layer are preset via automatically adjustable bolts. As a result, measurements do not need to be taken and the operator can quickly position the rafters and beams correctly.

An overhead travelling crane is hung above the tables to provide two handling systems for each table. With these handling systems, the beams are inserted and the panels are attached. A blowing plate is also fitted to blow the insulating materials into the roof and ceiling elements.

The CNC-controlled multifunction bridge manages all planking tasks. Due to the limited amount of space available, the width of the machine was adjusted specially for Regnauer, making the multifunction bridge easy to integrate. The tool changer attached to the bridge has slots for twelve different tools, so that the relevant tool can be selected according to requirements. In addition, it is equipped with a special unit for automatic storage, application and fastening of roof lathing, for example.

All roof and ceiling elements are manufactured using the production system. 90% of these elements are delivered to the building site with the room-facing covering material pre-assembled. This high level of prefabrication is advantageous especially with the elements clad with plasterboard panels, as the heavy plaster compounds are difficult to work with. A 30% increase in performance was achieved with the new plant.

Images: specialist magazine Bauen mit Holz / Regnauer Fertigbau / Markus Langenbach

“A 30% increase in performance was achieved with the new plant.”Markus Leppin, Regnauer Fertigbau

Office Building of the Future

Since more than 85 years Regnauer Fertigbau produces vital houses and vital commercial buildings in Seebruck. Well-trained employees and modern CNC-Technology guarantees accuracy and profitability.

Website of Regnauer Fertigbau