Two solutions. One interface. Countless advantages: SmartWOP and productionManager

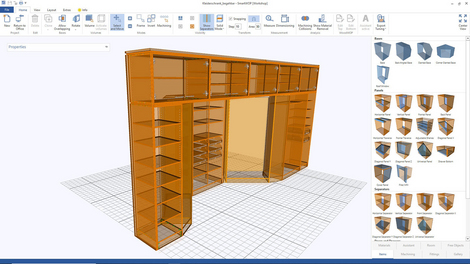

Are you already using the SmartWOP CAD/CAM system? Then here’s something you need to know: Our "SmartWOPConnect productionManager" interface connects the SmartWOP CAD/CAM system with the digital job folder, productionManager, ensuring consistent workflows in your company.

Are you already using the SmartWOP CAD/CAM system? Then here’s something you need to know: Our "SmartWOPConnect productionManager" interface connects the SmartWOP CAD/CAM system with the digital job folder, productionManager, ensuring consistent workflows in your company.

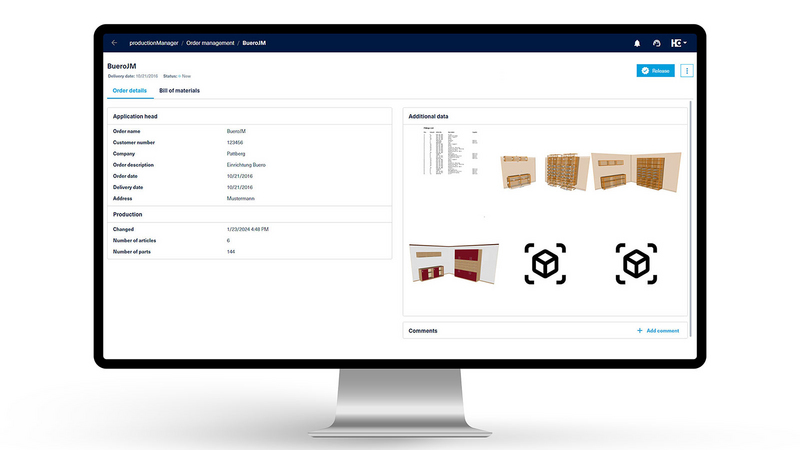

In concrete terms, this means that you can transfer your orders, including all associated documents and drawings, from the SmartWOP CAD/CAM system to productionManager with just one click. All order data for work preparation and production, such as article and component information including CNC programs and 3D drawings, is then available in productionManager.

The integrated 3D viewer allows you to view your planning in a zoomable and rotatable 3D view, including textures and sequential numbering, and to visualize the entire order. The components of your order can be shown and hidden directly in the 3D viewer of the digital job folder. You can also measure distances between components.

But that's not all: as the orders are available in productionManager, they can be transferred to other apps and digital solutions with a click. For example, if you want to optimize your order, simply send it directly to the optimization software for panel cutting (intelliDivide Cutting) or the nesting process (intelliDivide Nesting).

You can also easily track the processing status of your components, as the order progress is visible in real time in productionManager. This ensures seamless digital communication between work preparation and production. While we're on the subject of seamless communication: The digital job folder offers you another plus point by allowing you to enter comments: all employees, whether in work preparation or production, have the option of entering comments directly in the web app and informing responsible colleagues about damaged components, for example, or adding further important information to the existing order.

Interested? Find out how to subscribe to the interface here.