HOMAG India introduced SAWTEQ O-100.

HOMAG India introduced SAWTEQ O-100, to address this growing industry-level challenge! SAWTEQ O-100 is highly suitable for woodworking shops that are ambitious. The newest model of the HOMAG panel dividing saws is equipped with everything needed for cutting single panels & small batches.

Due to the changing consumer demographics such as rising consumerism, rapid urbanization, growing population, the fast adaptation of Western lifestyle, improved standard of living, the constant need for establishing social status, the rise of millennial’s in active workforce, the need for furniture of different types, styles have also been growing.

The furniture-making business in India is defined by cost minimization, customization, and supply chain management. Improved infrastructure, rise in the tourism and hospitality industry, the boom in the real estate business, growing need for furniture of different types, styles, for different spaces like commercial offices, houses, hotels, resorts, etc. Encouraging small woodworking shops to expand their furniture manufacturing business.

Despite the ongoing market fluctuations, overall, the market potential for the furniture-making business looks very bright. The furniture manufacturing business is the sun-rising industry in India & it makes up 0.5% of India’s GDP.

A few major factors limiting small-scale woodworking shops to expand their business are choosing the wrong panel-cutting machines, non-availability of skilled labour & increasing operational expenditure. Small-scale woodworking companies use sliding table panel saws for cutting. When their business starts growing, they start adding more sliding tables saws to improve production. Around 85% Indian woodworking industry is unorganized, out of which more than 50% of them are using two panel saws & around 5% are using 3 or more sliding table saws. It’s no surprise that around 2500 sliding table saws are sold in India every year.

Sliding table saw or panel saw comes with multiple limitations. Its needs:

- 3 skilled operators,

- Depending upon skill level & material,

- Around 40 to 50 boards can be cut per shift.

Small & ambitious woodworking shops with batch production have no option but to keep on adding more and more panel saws to match the growing demand. Adding more panel saw machines means:

- You need more space,

- Pay more rental charges for factory space,

- More bank loans,

- More electricity charge (hence compresses air and dust-extraction)

- You need to hire more skilled machine operators,

- Rising manual errors,

- Increased off-cut materials,

- Inconsistent quality,

- Safety issues & steep increase in indirect overheads.

Buying a fully automatic beam saw which costs around five times of a panel saw does not make economic sense for small-scale woodworking shops as most of their customers are from the middle-class segment looking for quality furniture at a reasonable price. Scarce availability of skilled CNC machine operators makes the problem much worse.

HOMAG India introduced SAWTEQ O-100, to address this growing industry-level challenge!

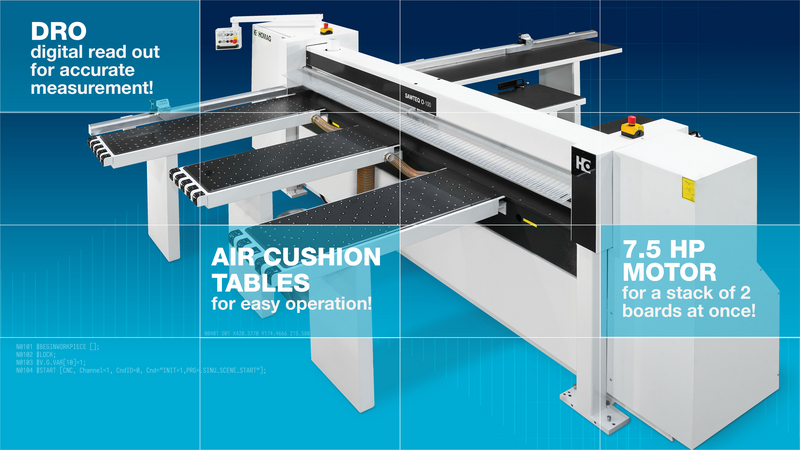

SAWTEQ O-100 is highly suitable for woodworking shops that are ambitious. The newest model of the HOMAG panel dividing saws is equipped with everything needed for cutting single panels & small batches. The SAWTEQ O-100 panels costs hardly more than a well-equipped sliding table saw while providing a much more precise & efficient cutting process with semi-skilled operators. A clear material flow around the saw & material handling working at the saw further increases the capacity. In addition, digital assistants help the operator to optimize the entire cutting process in terms of quality, quantity, and sustainability. This is achieved by proven HOMAG technologies.

In short, the panel dividing saw SAWTEQ O-100 is the solution for ambitious woodworking shops to improve productivity, and precise manufacturing at a reasonable price!

- Ergonomic design saves time, space & enables safe operation.

- Processing of a stack of 2 boards at once enables high productivity with precision, cutting quality & angular accuracy.

- Low maintenance costs because the design has small number of wear & tear parts.

- Automatic Cutting Feed: only 2 operators are required.

- Strong & efficient Suction in the saw carriage for good dust extraction.

- Cutting production Set for optimized digital assistance (optional)

- Smooth movement by airable & perfect measurement by DRO.

- Indian furniture market was valued at $ 17.4 billion in FY21. It is predicted to reach $ 37.7 billion by 2026, growing at a double-digit CAGR of 13.37% during 2020-2026.

- The size of the Online furniture retail segment grew from $ 300 Million in 2017 to $ 920 Million in 2020 recording a CAGR of 32%.

- Indian furniture rental industry was estimated at $ 4.1 Billion in 2020 and is fore-casted to grow to $ 13 Billion by 2025 at a CAGR of 26%.

HOMAG Service promise – beyond selling a machine.

In the last six-month HOMAG India spend significant amount of time to optimize the presentation of the machine, usability and features. The saw can easily handle book cuts (multiple sheets up to 60 mm), with the “Cutting Production Set” the Digitalization also for smaller businesses can be realized, the topics of cash-flow issues such as in too many off-cuts and waste can be reduced by the optimization algorithm in the set. All HOMAG Sales and Service Members are qualified to train the customer and workers in detail in how to use the machine, organize the material flow in the factory (incl. factory layout design) and the machine handling flow. Only 2 workers, we call one the operator and one the helper can cut any pattern. The air tables create a smooth gliding of the sheets in the front, the DRO (digital read out) at the angular fences make the measuring perfectly accurate, the communication between operator and helper is easy and both routinely split the workload. Stacking the final parts on pallets or in collecting trollies defines the next process step. Did you know, trouble-shooting and digital assistance you can get from the HOMAG India hotline as fast as picking up the phone/via online call.

We are looking forward hearing from you, serving you to create further racking for your thriving business.

Any questions? Get in touch with us!

HOMAG India Pvt. Ltd.

Sales: +91 80 69495656