granIT Basic

The new entry-level opportunity for digitalization of prefabrication in small- and medium-sized carpentry businesses.

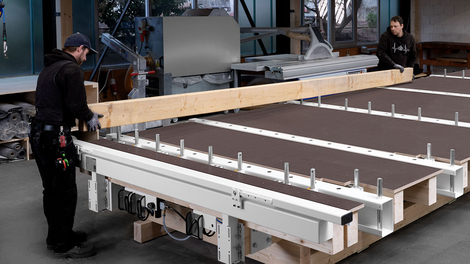

For more than 30 years, WEINMANN partner granIT has been digitalizing the production of wood frame construction elements in industrial companies by providing a complete digital representation of work preparation and production. With a new configuration of the Manufacturing Execution System (MES), we can now also offer a system controller for woodworking shops.

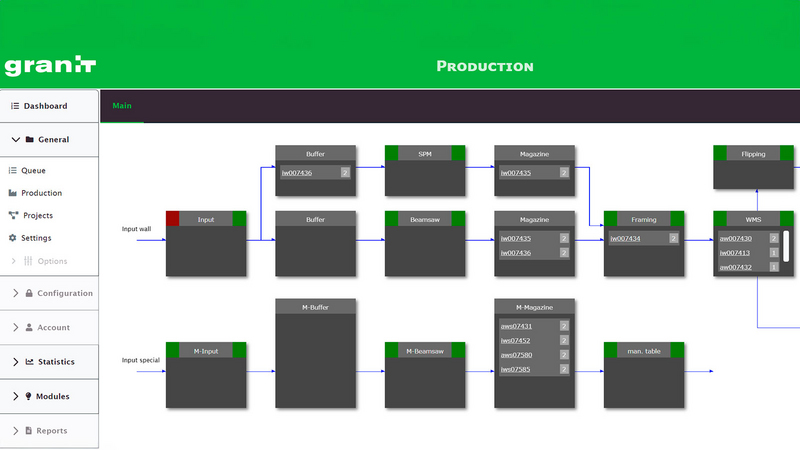

The web-based software granIT enables the digitalization and management of production plants in timber construction. granIT can be used to define the production order of the wood frame construction elements at each workstation in the production line. This also includes the automatic provision of digital work instructions to manual workstations by using customer-specific end devices with an up-to-date browser. This means that you have a clear order and can work in cycles with a transparent overview of the overall progress of the construction project.

Highlights:

- Management and control of up to six individual stations (WEINMANN and HOMAG machines as well as manual workstations)

- Automatic control of up to two machines (WEINMANN/HOMAG)

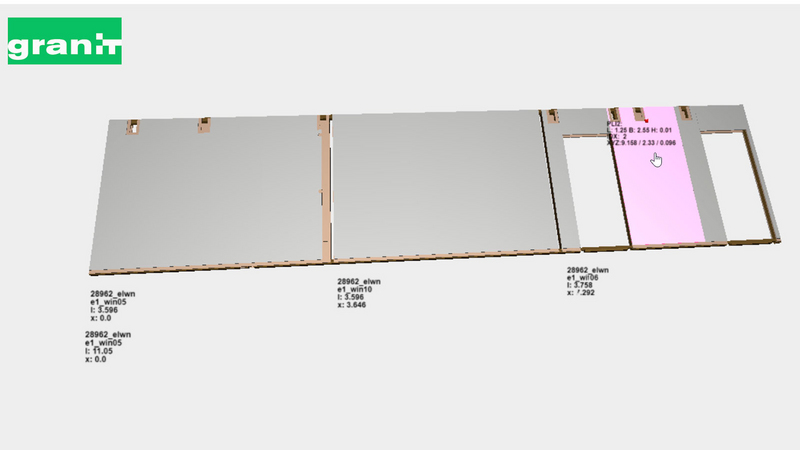

- Modern 3D visualization of data records, production schedules and reports for optimal overview and control

- Recording and evaluation of the booking times of all machine and manual workstations

Functions:

- Work preparation: Production orders are imported, sorted into an order and released for production at all stations by one employee.

- Digital production and feedback: Drawings of the frame work, the panel layers or their processing steps are created automatically based on .wup files. These can be printed directly or displayed as a PDF on a manual workstation and confirmed digitally.

- Reports/project status: All relevant information, such as the production status, the machine assignment or the project status, can be accessed via a web browser. You can design your own reports individually.

Do you have specific questions?

Wolfgang Bock of granIT is happy to answer your questions and you can contact him at wolfgang.bock@granit.de!