Mobili is a leading designer and manufacturer of inspired, innovative workplace solutions. The company’s home is in Yorkshire, yet the name Mobili can be found in offices globally, and it is synonymous with well-designed furniture of the highest quality.

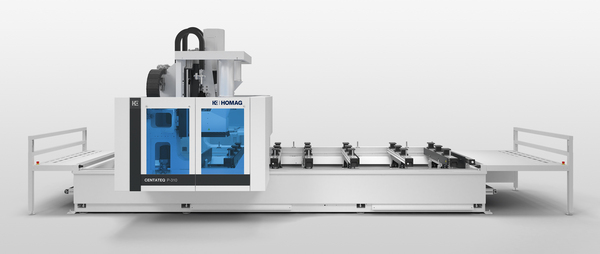

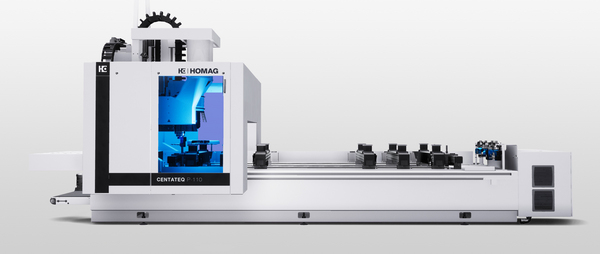

As demand for its products grew and its portfolio expanded beyond desking to include a wider range of office furniture, the company recognised the need to increase its production capacity. To support this growth, Mobili invested in three state-of-the-art HOMAG machines: the CENTATEQ E-310, CENTATEQ P-110, and DRILLTEQ V-200.

A long-standing partnership

Ben Greenwood, Operations Manager at Mobili, explains why HOMAG was the natural choice for this latest investment: "Over the last 10 years, as we've upgraded machines, we've always leaned towards HOMAG. The majority of our equipment is from them because their service is consistently excellent, and their loyalty schemes add real value. We trust HOMAG as our OEM, and it makes sense to keep everything within one ecosystem."

Before finalising the purchase, Mobili visited other HOMAG customers to see the latest technology in action. Already familiar with previous versions of these machines, the team was confident in their capabilities and took the opportunity to invest in higher-spec models to maximise efficiency and output.

As Ben explains, “We had the budget to invest in the higher specs, and we were very keen to take advantage of the latest advancements in HOMAG’s technology.”

Seamless installation and zero disruption

When it came to installing the new equipment, Mobili worked closely with HOMAG to ensure a smooth transition.

“Installation was as smooth as it could possibly be,” Ben recalls. “It was a joint effort between HOMAG and our team – we made sure the space was clear and ready for them. When it came to delivery and setup, everything was up and running in no time. Training was also seamless – some of our team were already familiar with the machines, but the refresher training ensured we were fully operational within a day.”

One of the most impressive aspects of the installation process was the complete lack of disruption to production.

“There was literally zero disruption, which is unheard of,” Ben says. “I’ve done many projects like this, and there’s always some level of disruption, but in collaboration with HOMAG, we managed to move things around and utilise our resources in such a way that we didn’t see any dip in output. HOMAG’s clear communication was key – they told us exactly what we needed to do to ensure a smooth transition, and we followed every step. It was absolutely worth it.”

Boosting capacity and efficiency

Since installing the new HOMAG machines, Mobili has seen an immediate impact on production capacity and efficiency.

“We’ve instantly gained an additional 25% capacity in the factory,” Ben states. “The new machines also allow us to use one of our older machines differently, extending its lifespan. Previously, we were running the same level of work through two machines – now, the two new HOMAG machines handle that workload, while the older one is dedicated to larger, high-value products. This makes us far more flexible than before.”

The investment has also led to a more efficient factory layout, improving workflow and productivity.

“The new machines forced us to rethink the factory layout, creating a much better flow,” Ben explains. “Combined with the advanced capabilities of HOMAG’s latest technology, our output has increased significantly. We’re expecting the machines to pay for themselves within three years.”

A painless experience with HOMAG

For Mobili, working with HOMAG has always been a positive experience, and this latest investment was no exception.

“The biggest thing for me is that it’s painless,” Ben says. “The HOMAG team is so knowledgeable – they take the time to understand what we need and provide the right solution. There’s no pressure, just expertise. Once we give the go-ahead, we know exactly how everything is going to go. Their communication is exceptional, and that takes all the worry out of the process. Everything works like a well-oiled machine, which in this industry is worth its weight in gold.”

Looking ahead

With its new HOMAG equipment in place, Mobili is well-positioned to continue growing, delivering high-quality, innovative workplace solutions to its customers.

“We’re always thrilled with HOMAG machines and their service,” Ben concludes. “Everything went smoothly and exactly according to plan. Now, with our new kit, the factory is performing at its best – we couldn’t be happier.”

For more information or a demonstration of HOMAG’s machinery and software, please contact HOMAG UK on 01332 856500, option 4 for the sales department. Or email info-uk@homag.com

“Everything went smoothly and exactly according to plan. Now, with our new kit, the factory is performing at its best – we couldn’t be happier.”Ben Greenwood, Operations Manager at Mobili