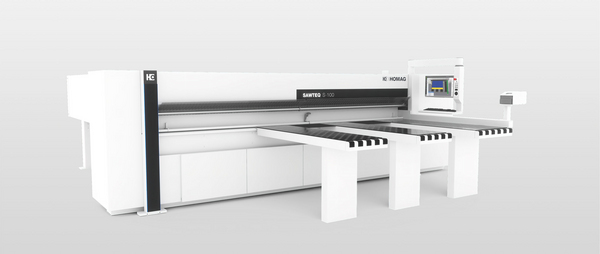

The Schreinerei Schwieck joinery in Braubach, Rhineland-Palatinate, is known for its high-quality individual pieces manufactured to the customer's exact wishes, down to the millimeter. Founded in 1978, the company is a successful second-generation business that is constantly changing — both in terms of its own product world and in terms of production technology. The latest investment is the SAWTEQ B-130 (now S-100) horizontal panel dividing saw from HOMAG.

The Schreinerei Schwieck joinery is a real family business. In addition to the owner Jörg Schwieck, the seven-person team also includes his sister Dagmar and the company founder Detlef Schwieck. Since the company was transferred to his son in 2016, Detlef Schwieck, now aged 73, has remained actively involved as an employee.

Focused on furniture and office furnishings

With two journeymen and two apprentices, the Schwiecks primarily produce furniture and office furnishings for business and private customers. There are also special orders. However, Jörg Schwieck sees the future in furniture construction. According to him, this has been their biggest growth area since the commissioning of the new panel dividing saw from HOMAG. "The SAWTEQ B-130 (now S-100) acts like a turbo."

Panel cutting with optimization potential

The saw was put into operation in 2021. Until then, cutting was time-consuming and labor-intensive. Before the introduction of the new saw, two people had to first balance the unprocessed panels on an upright panel saw and cut them in half to get manageable panels. These were then cut to size on a sliding table saw. "This was also only safe and gentle on the materials with two people," recalls Jörg Schwieck.

Same output in a third of the time

Now, only one saw operator is required. Processing is also significantly faster: The same output is achieved in one third of the time — with improved cutting quality. Detlef Schwieck adds: "Looking back, I have to say that we invested 20 years too late. In fact, at the turn of the millennium, we did consider purchasing a horizontal saw with automatic panel storage in addition to the HOMAG CNC that we bought back then. At that time,

both machines were rarely used in the joinery trade. "In addition, we would have had to make greater alterations to make room for them." That's why the project was not implemented in the end.

Reduces material consumption

The new SAWTEQ B-130 requires little more space than a well-equipped sliding table saw. However, the difference is that the new saw completes the cutting process faster and more precisely. The reason for this is the automated cutting and the CADmatic 5 machine control unit with integrated CADplan cutting pattern optimization. "Cutting pattern optimization used to be like playing Tetris: tricky, time-consuming and in the end, the pattern didn't work out. It has become much easier with CADplan," explains Jörg Schwieck. Part lists and panel lists are simply imported in CSV format for each job. CADplan then generates the optimized cutting patterns directly at the saw. This speeds up the process and minimizes material consumption.

Intuitive guidance through the cutting process

For Schreinerei Schwieck, the highlight of the SAWTEQ B-130 is the intelliGuide Classic. This assistance system guides the machine operator through the cutting process intuitively using LED signals. The operator can work through the cutting pattern without looking at the monitor. This ensures smooth, ergonomic and safe processes. "Even apprentices can take over the cutting of individual panels—which make up 98% of the material in our company—after a short training period" says Jörg Schwieck. "The younger generation in particular is impressed by the ergonomic and intuitive operation of our new saw." In times when there is a lack of skilled workers, this enthusiasm is more important than ever. "We are a training company that wants to retain junior employees in the long term. We achieve this through our family-friendly cooperation and a modern machine pool," stresses owner Jörg Schwieck.

Impressive quality and service

For consistent production, the joinery relies on HOMAG machines, from cutting through edge gluing and CNC processing right up to sanding. The similar operation also makes the day-to-day work easier. In addition to the processing quality, the Schwiecks are also impressed by the personal service: "The chemistry is right. We work well together, which makes a difference for us."

“The younger generation in particular is impressed by the ergonomic and intuitive operation of our new saw.”Jörg Schwieck, Managing Director of Schreinerei Schwieck