An article from the specialist magazine BM, May / 2017. Here you can read the article on BM-Online.

Berthold Mayer has experienced some intense years – and probably also has many to come. This soon becomes clear when talking to the friendly and busy master joiner during a visit to the workshop in Bad Säckingen, located on the Swiss border.

Today, Mayer employs 11 people, but this wasn’t always the case. “When I set up, I was a lone warrior for the first few years. In 2008, I honestly asked myself whether I should give up or really go for it,” he remembers with an amused smile. And indeed, he gritted his teeth and stepped it up a notch. He had a clear aim: to turn the company into a high-performance manufacturing specialist and become a reliable and highly-flexible partner supplier for joiner colleagues.

And that’s exactly what he did: “I then bought a horizontal panel saw, an edge banding machine and CNC, and I used an easy-to-operate furniture configurator to take my first steps with software. That also went well – despite the fact that I was a real IT novice up until then.” In those days, Mayer had little free time: on Sundays he would plan and design in the office until he dropped, and from Monday to Saturday he would work on production in the workshop. “I wouldn’t have been able to do it without the incredible amount of understanding and fantastic support from my wife”, he says of this time, and one can see that the pair make a great team.

Flexible partner for joiner colleagues

He believes that his concept has a future and will shape the industry even more than before: “Joiner’s workshops are becoming smaller and smaller and cannot provide all the machines for all production tasks. We are a reliable and effective subcontractor for them.” And he adds: The young generation is very open to working with specialists like us. Of course, we have to keep proving ourselves to our colleagues by adhering to deadlines and providing the best joinery quality. And it goes without saying that we occasionally have to handle rush jobs.” Berthold Mayer and his 11 colleagues handle all this in Work Preparation and Production. Customer proximity also plays a role, as Mayer sticks to an operating radius of approximately 100 km around Bad Säckingen. A wide range of joiner colleagues in Switzerland have come to highly value the outstanding expertise of the specialist supplier and have become loyal regular customers.

The product range comprises cutting with and without edge application, completed furniture and carcasses (including roof pitches), 5-axis CNC processing, countertops including corner joints and cut-outs and also fronts and coverings made from Norit fire protection boards. Berthold Mayer now has around 120 customers in the field of carpentry. Around 30 of them order furniture, supply parts and more on a very regular basis, and this looks set to increase. In the majority of cases, they deliver them themselves. “In this way, we can ensure that our parts are delivered to our colleagues intact.”

Heavy investment in software and machine

As a result of the positive development, Berthold Mayer has made further investments, in 2012 he invested in a combination saw-storage system (from Holz-Her/Barbaric) and in 2015 he then invested in a new 5-axis CNC, a nesting machine and an edge banding machine (all from Holz-Her). In terms of machine technology, this paved the way for carrying out dividing work on either the panel saw or the nesting machine.

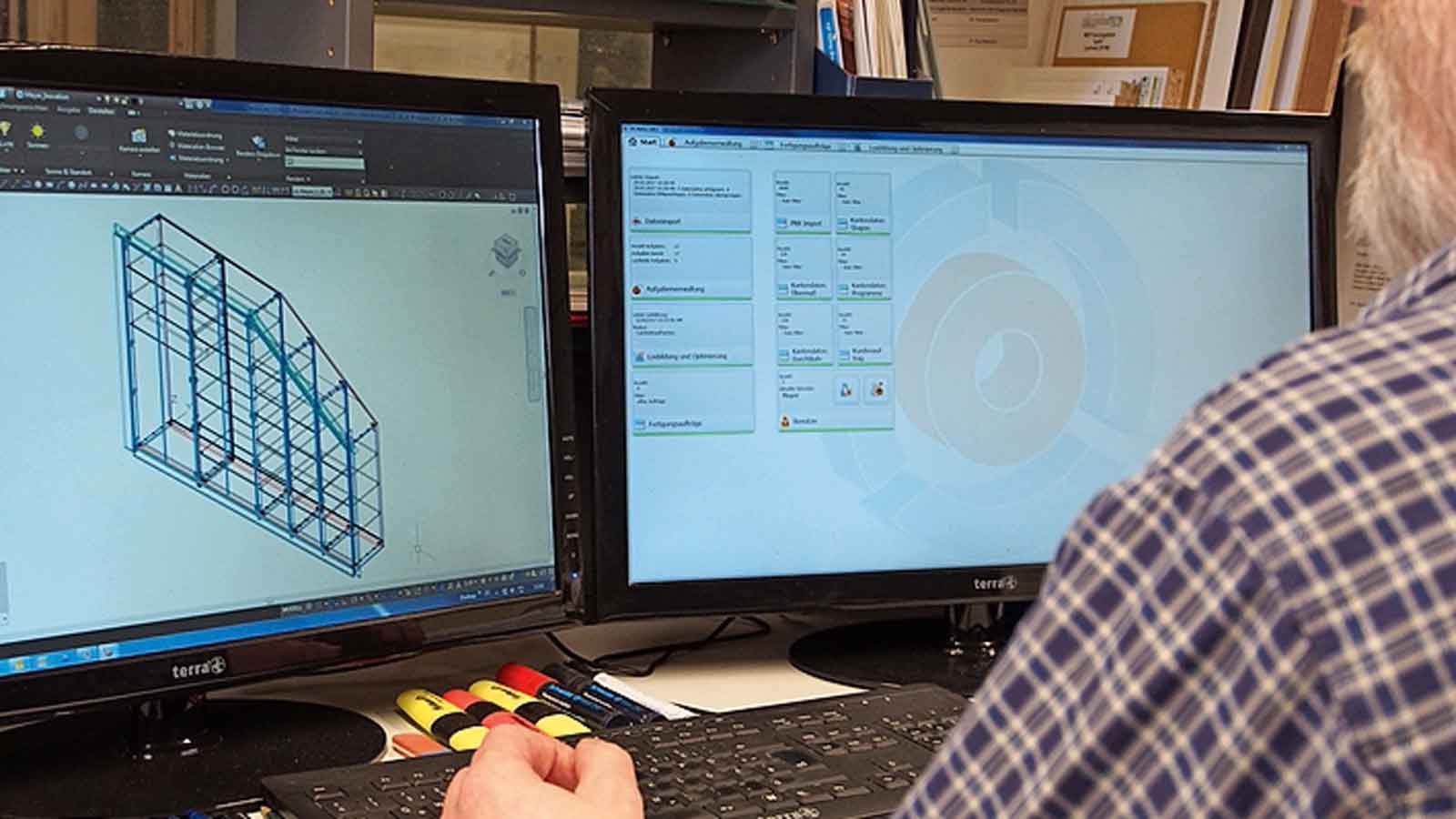

And since the designs have become increasingly complex and/or more individual and Berthold Mayer is looking to provide his partners with a powerful online configurator, he also decided to purchase a CAD/CAM system from Imos in 2015. In addition, he had already started to use the 3D generator from Truncad and the industry program from OSD.

A quantum leap in edge processing

But it was not long before the next project arose. Berthold Mayer saw considerable optimization potential in the field of edge processing. Consistent automation and noticeable increases in efficiency were what he wanted to achieve here. So he invested in a new edge banding machine from HOMAG together with an automatic handling system, which includes a return system, from Barbaric. What is special about it is that the plant is completely unmanned and has capacity of around 1000 pieces/shift.

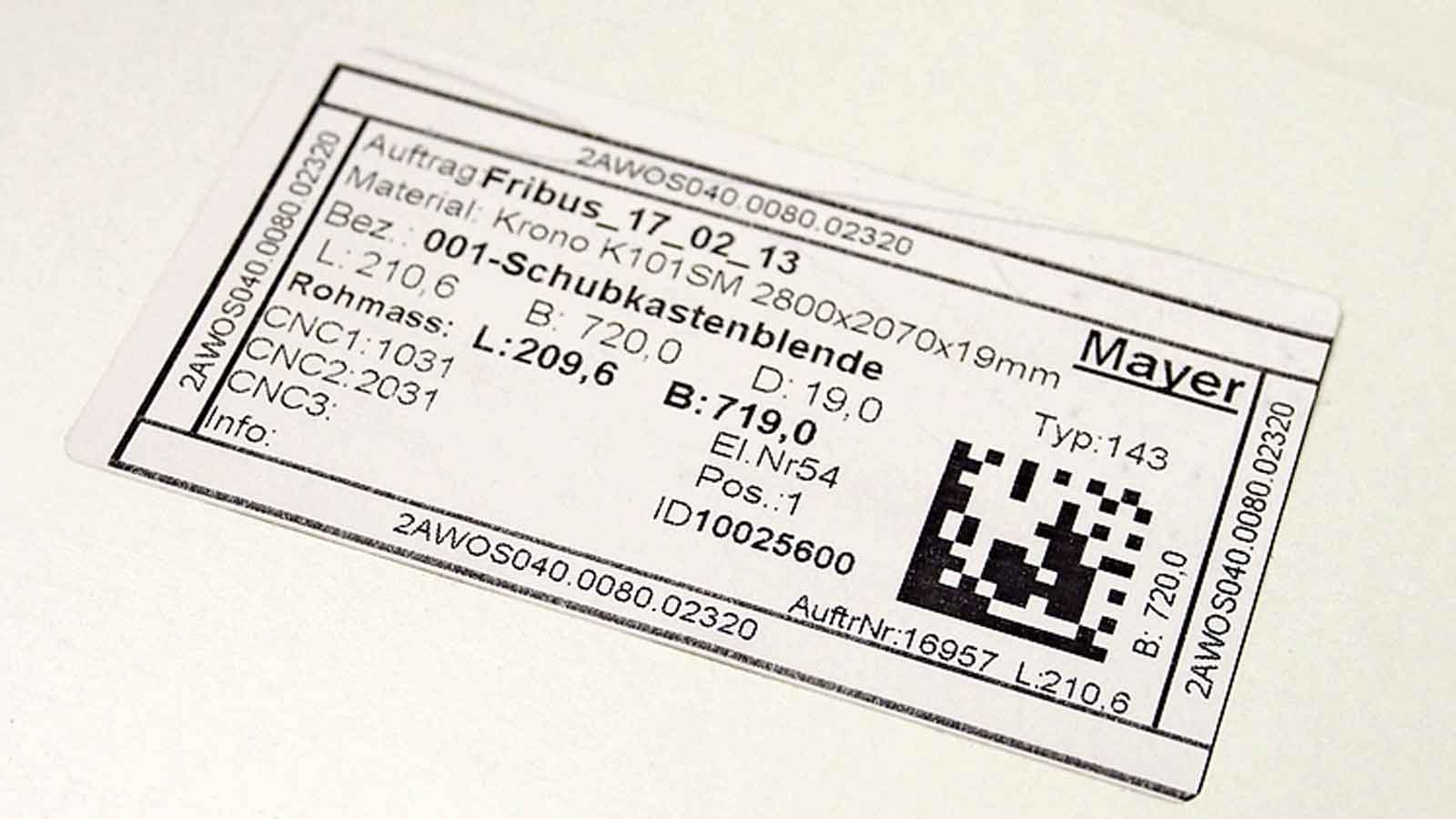

First the parts are sized on the panel saw or the nesting machine and currently barcode labels are still applied to them manually (however this is soon to be carried out automatically in the panel store). As they are brought into the edge cell, the labels are scanned automatically and all necessary information is then transferred to the handling system and the HOMAG machine control system. However, for this to be carried out in this way, all processing, adhesive and edge material information must also be stored, such as information about de-stacking and much more.

Manufacturing execution system opens up new possibilities

This is exactly where the experts from HOMAG Consulting & Software came into play. They devised a comprehensive data concept and, in consultation with the software suppliers involved, they installed the ControllerMES manufacturing execution system (MES). Mayer was and is the pilot customer for this new software, which aims to make Industry 4.0 possible for ambitious woodworking shops. The MES has since become an indispensable control center in the software landscape at Mayer.

It supplies the cut and nesting optimization systems with data, generates the required, and highly complex data records for label printing and edge processing and allocates unique part IDs. This information is essential for the operation of a fully-automatic edge cell, like the one at Mayer.

Although the project was initially focused on the unmanned edge processing plant, the MES will also soon open up completely new streamlining potential, even in other production areas. Everything that Berthold Mayer is coming up with is very exciting.

A great deal achieved and still more to do

Berthold Mayer has defined a clear strategy for the future: “It is not necessarily more employees that are needed for growth, but intelligent automation and increases in efficiency at the level of technology. With the edge cell, we have now taken the first, very, very large step here.”

But he also knows that automation in the workshop ultimately means more expense in the office and considerably higher IT requirements. All in all, he is extremely pleased, not only about the considerable increase in efficiency and quality during production, but also that the manufacturing execution system results in time savings of a whole 20% in Work Preparation.

Fotos: Fachmagazin BM / Christian Närdemann