Harrison Collier, designer and manufacturer of bespoke interior cabinetry, was established in 1990 by Managing Director Simon Harrison in a small Cheshire barn. From those humble beginnings it has climbed to the top of its niche, serving a discerning clientele and working closely with interior designers, architects, developers, and private clients across the UK specialising in full house installation projects.

Operating from a 14,000 sq ft purpose-built facility in Prescot, Merseyside, Harrison Collier has a 30-strong team and delivers an end-to-end service – from design and CAD drawings to manufacture, finishing, and installation. It’s a company that goes from strength to strength, and with this in mind, they turned to HOMAG for their latest investment.

The need for new machinery

“The times were changing, our business was growing, and so we decided it was time to upgrade our machinery,” explains Simon. “We already had a couple of older HOMAG machines – a Vantage nesting CNC and a BHX 050 – that had been reliable for over a decade. But technology has moved on and it was time we moved with it.”

Why HOMAG?

The choice of supplier was straightforward. “We’ve used HOMAG machines for years and they’ve always served us well. There was never really a question of looking elsewhere.”

Their long-standing relationship with Jon Lawman from HOMAG made the process even easier. “We spoke to Jon about what upgrades would suit us best. What really excited us was learning we could integrate our Lamello jointing system with the new CNCs.”

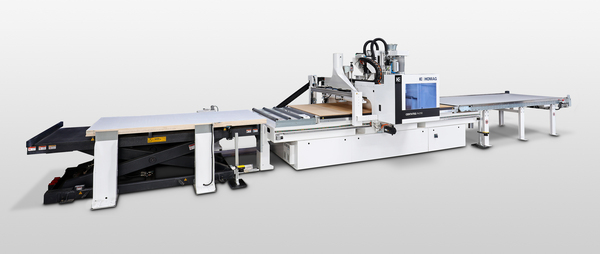

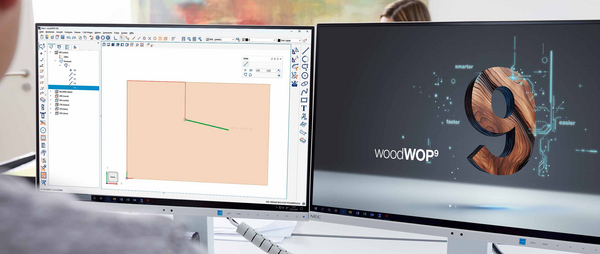

Simon and his team had purchased a handheld Lamello unit a few years earlier. “It worked an absolute treat,” he says. “Then, once we’d decided on the CENTATEQ N-210 and DRILLTEQ V-200, we found out HOMAG could integrate Lamello through their woodWOP software. That was a complete game-changer.”

Installation & training

“Delivery was bang on time and caused minimal disruption – can’t ask for more than that,” says Simon.

Four team members were sent to HOMAG’s Castle Donnington showroom for training. “They had a great trip, got to grips with the basics, and were ready to go as soon as the machines were installed. These CNCs are incredibly intuitive – the lads took to them like ducks to water.”

Operational improvements

The benefits of the upgrade were immediate. “The Lamello integration alone has made us far more efficient,” says Simon. “Aside from that, the general upgrades in the technology are working wonders for our operation. We have a lot more flexibility with these machines, and they’re so user-friendly that more members of staff can operate them, which has increased capacity.”

The company also benefits from remote programming. “We can now programme jobs from the office, sending the CNCs complicated instructions from the comfort of a chair at the click of a button. It saves a lot of time and effort and really just simplifies the manufacturing process.

“And of course, the finish of the products produced with these CNCs is second to none. Quality is everything to us, so it’s great knowing our machines deliver it without fail.”

Working with HOMAG

“We can’t fault HOMAG’s service,” says Simon. “If something goes wrong, they deal with it quickly. And with the Lamello integration, they really went the extra mile. They’re a first-rate supplier.”

Looking ahead

“We’re not looking to expand further for the time being,” Simon adds. “We’re happy with our space and our niche. This investment was about making the most of what we’ve got – being as efficient as possible while continuing to deliver exceptional work. With these new HOMAG CNCs, we’re confident we’ll be doing just that for many years to come.”

For more information or a demonstration of HOMAG’s machinery and software, please contact HOMAG UK on 01332 856500, option 4 for the sales department. Or email info-uk@homag.com

“We can’t fault HOMAG’s service, says Simon. If something goes wrong, they deal with it quickly. And with the Lamello integration, they really went the extra mile. They’re a first-rate supplier.”Simon Harrison Managing Director