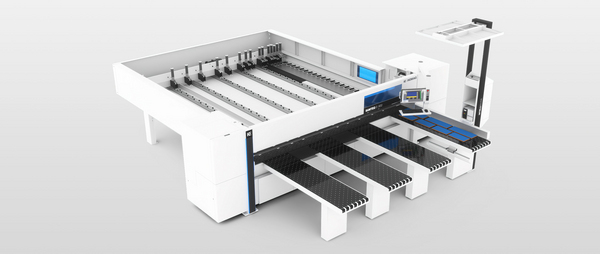

North London’s Cworkshop, specialists in cut-and-edge services for small and medium-sized furniture and interior businesses, recently invested in four HOMAG SAWTEQ S-300 panel saws, two EDGETEQ S-380 edge banders, and two XES 200 glue pot pre-heating stations to support its ongoing expansion. Here’s how it all played out.

Supporting small business with big capabilities

Since its founding in 2010 by two cabinet makers, Cworkshop has built its reputation as a fast, reliable manufacturing partner for small to medium-sized businesses.

“Our customers are often one- or two-man bands,” explains Antony Didjurgis, Founding Partner at Cworkshop. “They don’t have the space, equipment, or workforce to cut boards themselves – especially in London where space and labour are so expensive. We provide a hub where they can get their furniture boards cut, drilled, CNC’d, and edge banded quickly, with a turnaround time they can’t achieve on their own.”

To make this work, Cworkshop regularly invests in advanced, high-powered machinery that can not only get the job done quickly, but also to the highest possible standard.

The latest investment

As the company grew, more machinery was needed to keep up with demand. “We’ve opened new branches,” says Antony, “and those branches needed filling with machinery. We knew we’d be acquiring four beam saws and two edgebanders with glue pot pre-heating stations. The question was, which supplier could we trust to deliver the best return on such a large investment?

“We’ve been using HOMAG machines for over a decade – our oldest beam saw is 11 years old and still runs beautifully. However, for this latest investment, we did a market check, out of curiosity more than anything. In the end, nothing could compare with HOMAG.

“Aside from the machines, which are clearly first-class, HOMAG’s interfaces are in a league of their own – very easy to operate and fully loaded with everything the operator needs. HOMAG might not be the cheapest, but when you look at the full picture, the value is clear.”

The sweet spot in automation

The decision-making process was straightforward. Antony and his team visited HOMAG’s Castle Donington showroom, where Sales Manager Ian Woodall demonstrated different machine configurations.

“When I look at machinery, I want the sweet spot between too much and too little automation,” says Antony. “If it’s too automated, the operator has nothing to do and can lose focus. If it’s too manual, fatigue and mistakes creep in. With various quality of life upgrades and flexible configurations available, HOMAG finds the perfect balance.”

Improved workflow and product quality

One of the biggest gains from the new machinery has been workflow consistency. “We have all these HOMAG machines, and the interface makes it seamless to operate them as a collective.” Antony explains. “This saves us a lot of headaches, and of course, it’s a huge benefit for productivity.”

Quality has also reached new heights. “The accuracy is exceptional – you can adjust settings to the smallest possible degree. Much of it is automated, but a skilled operator can get absolutely flawless results with these machines.”

Interestingly, Cworkshop opted for smaller edge banders this time. “Edge banders are getting bigger and more expensive,” Antony says. “HOMAG’s S-380 does exactly what the larger machines do, just a little slower, and at a much smaller cost. It’s versatile, has a smaller footprint, and still produces the same high-quality finish.”

A strong relationship

Cworkshop’s long-standing relationship with HOMAG is a big part of why Antony keeps coming back. “The team are always friendly and helpful. We have a good working relationship with them, and their professionalism often shines, particularly during installations where things can get complicated. We’re particularly grateful to Simon Beasley, who organised these latest installations and was fantastic from start to finish.”

Looking ahead

The company’s growth shows no signs of slowing, and more HOMAG machines are already on the horizon. “We’re looking at investing in the future and HOMAG will be our first port of call. This latest investment was exactly what we needed to keep our expansion moving and HOMAG have really helped to move forward with our growth plans.”

For more information or a demonstration of HOMAG’s machinery and software, please contact HOMAG UK on 01332 856500, option 4 for the sales department. Or email info-uk@homag.com.

“We have all these HOMAG machines, and the interface makes it seamless to operate them as a collective. This saves us a lot of headaches, and of course, it’s a huge benefit for productivity.”Antony Didjurgis, Founding Partner at Cworkshop

Cworkshop

Cworkshop provides services and products for the furniture makers, interior designers and general builders.

cworkshop.co.uk