Return Conveyors LOOPTEQ O-600

Return Conveyors LOOPTEQ O-600

More flexibility for the material flow

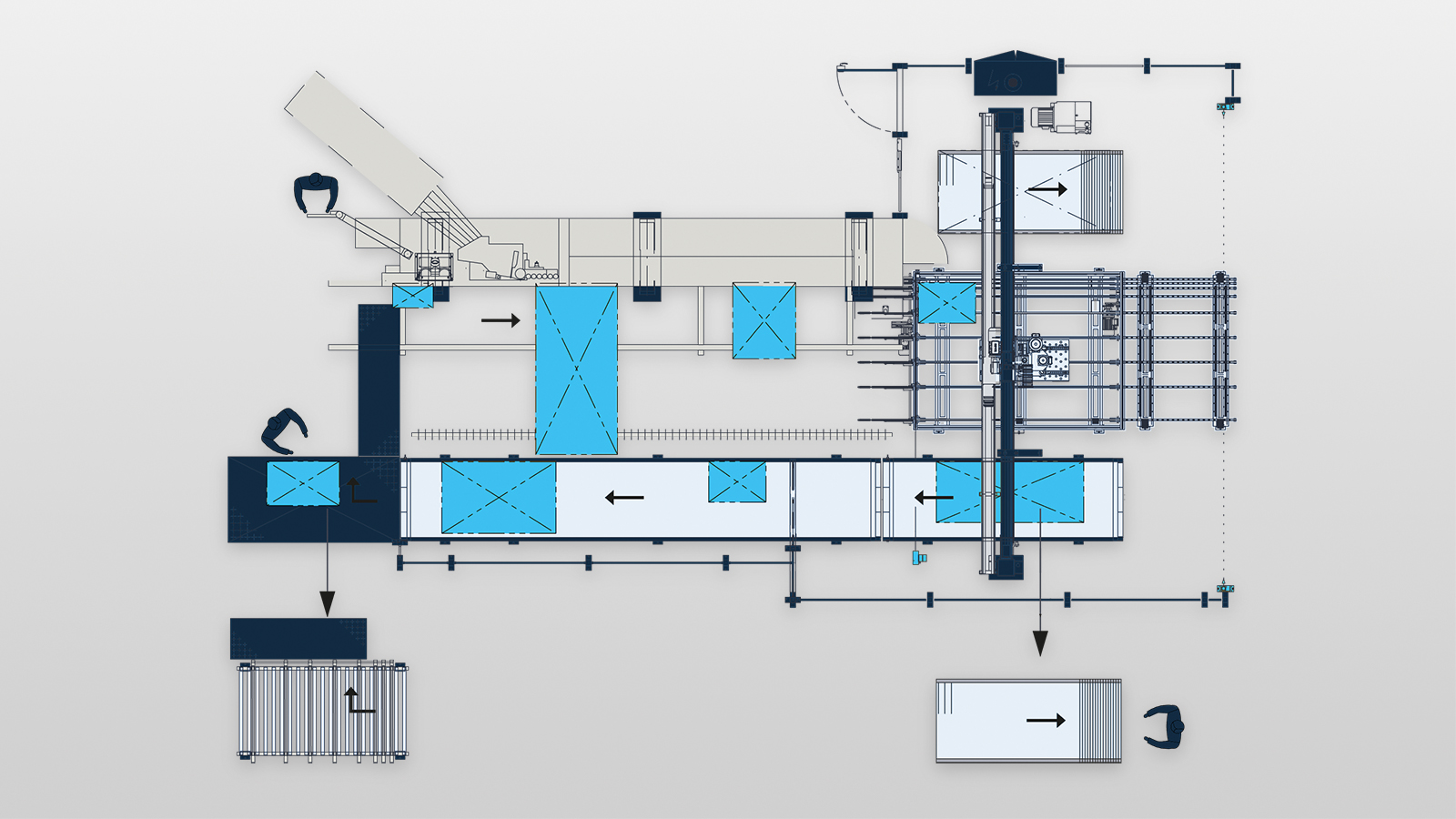

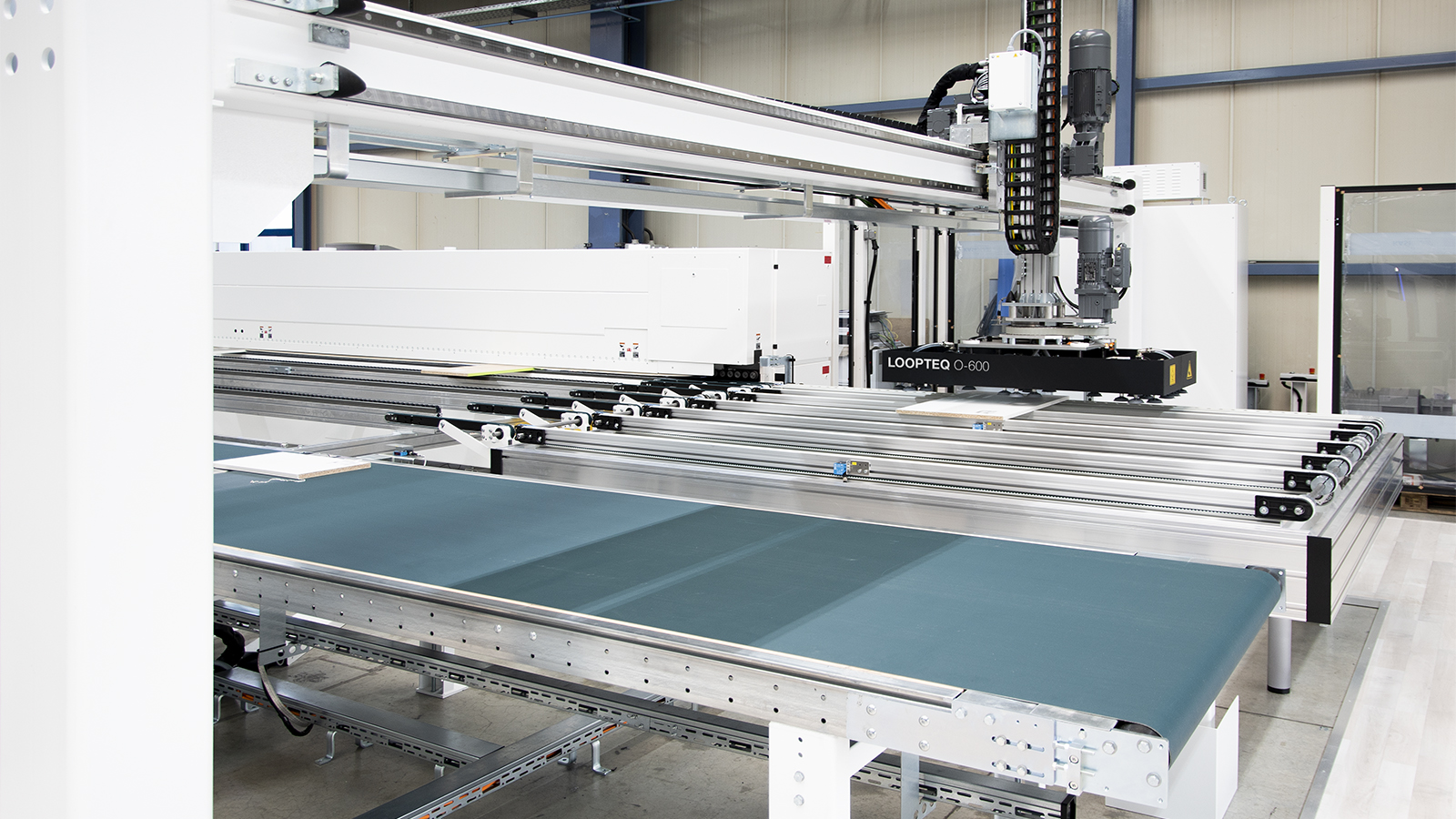

Stacking unit and return conveyor combined in one machine. The high automation degree makes the LOOPTEQ O-600 a real multi-talent. Finished workpieces can be fed out or stacked. The LOOPTEQ O-600 is best suited for customers with high material variety and a production with high automation degree.

Benefits

- Low quality costs - gentle handling via vacuum traverse

- Flexible operator organization - thanks to economic one-man operation

- Ergonomic working process - operator will be released from heavy physical work

- Intelligent automation - interlinked material flow with high capacity

- Efficiency increase - defined rotation for process optimized panel return

Images

Features

-

The LOOPTEQ O-600 perfectly harmonizes in size, capacity, and speed with HOMAG Group‘s unilateral edge banding machines

-

Up to 2 destacking places are optional possible, depending on requirements

-

High performance and an improved positioning accuracy thanks to a highly precise linear guideway

-

Higher dynamics and a smoother running due to an electronically controlled z-axis

-

Automatic turning of the parts (0°,+/- 90°, 180°)

-

Stacking without pit, no lifting table, no hydraulics neccesary

-

Simple belt cleaning equipment is already included in the standard

-

Energy savings of up to 30% thanks to a new electric drive of the z-axis

Technical Data

| LOOPTEQ O-600/25 | LOOPTEQ O-600/30 | |

|---|---|---|

| Workpiece length [mm] | 240 - 2,500 | 240 - 3,000 |

| Workpiece width [mm] | 80 - 1,200 | 80 - 1,200 |

| 4-sided processing* min. workpiece length [mm] | 240 x 120 | 240 x 120 |

| 4-sided processing* max. workpiece length [mm] | 2,500 x 1.200 | 3,000 x 1,200 |

| Workpiece thickness [mm] | 8 - 60 | 8 - 60 |

| Workpiece weight max. [kg] | 80 | 80 |

| Mass per unit area max. [kg/m²] | 25 | 25 |

| Working height [mm] | 835 - 950 | 835 - 950 |

| Feed Speed [m/min] | 12 - 36 | 12 - 36 |

*Larger workpieces can be returned or even fed out at 4-sided processing with manual support during crosswise offset and turning.

(Previous product name: Return conveyor BOOMERANG® TFU 520)

Here's how your colleagues produce

Brochures