Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

CNC Drilling and Routing Machining Centers DRILLTEQ H-600

CNC Drilling and Routing Machining Centers DRILLTEQ H-600

Extreme flexibility and varied connection possibilities

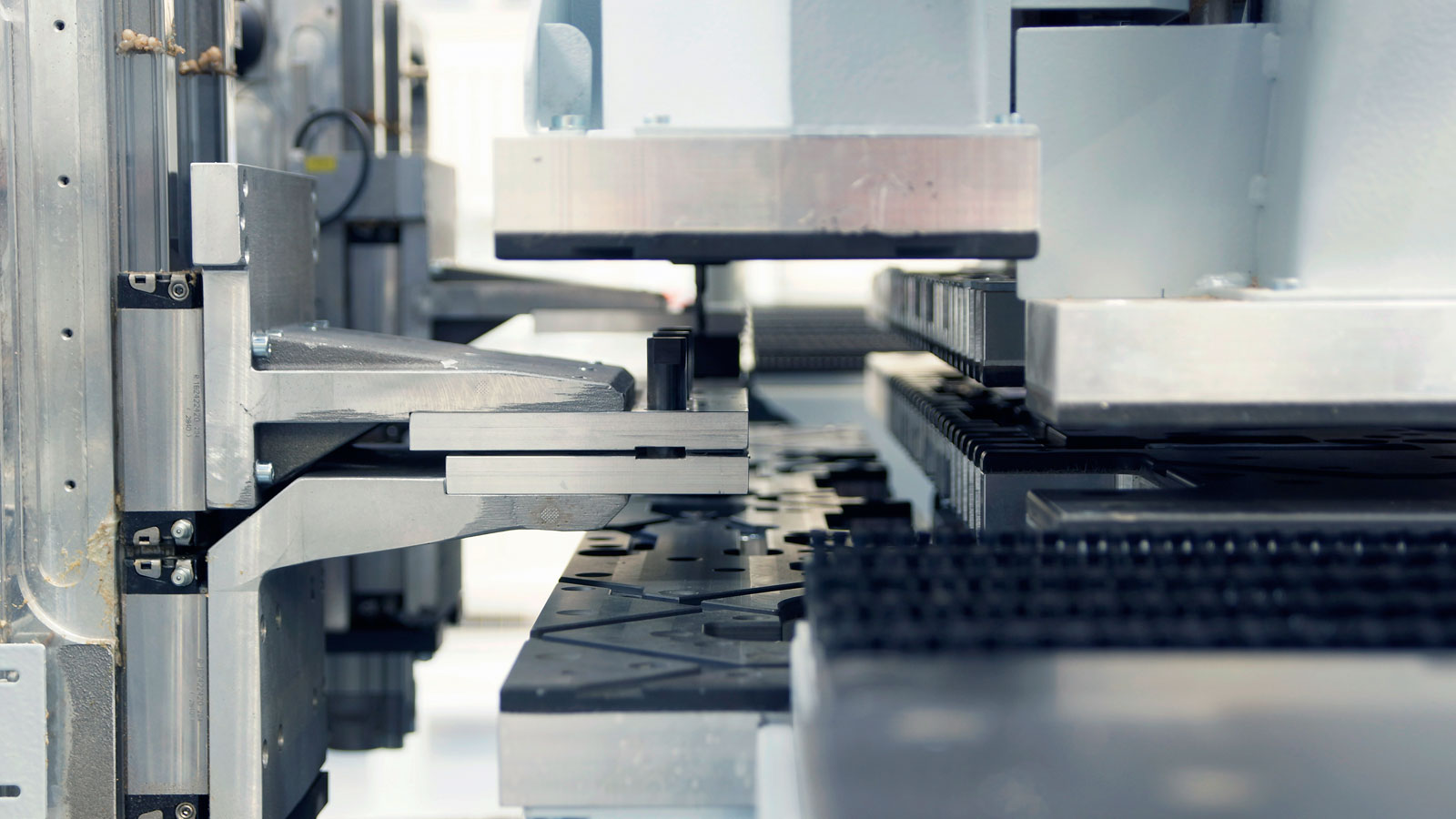

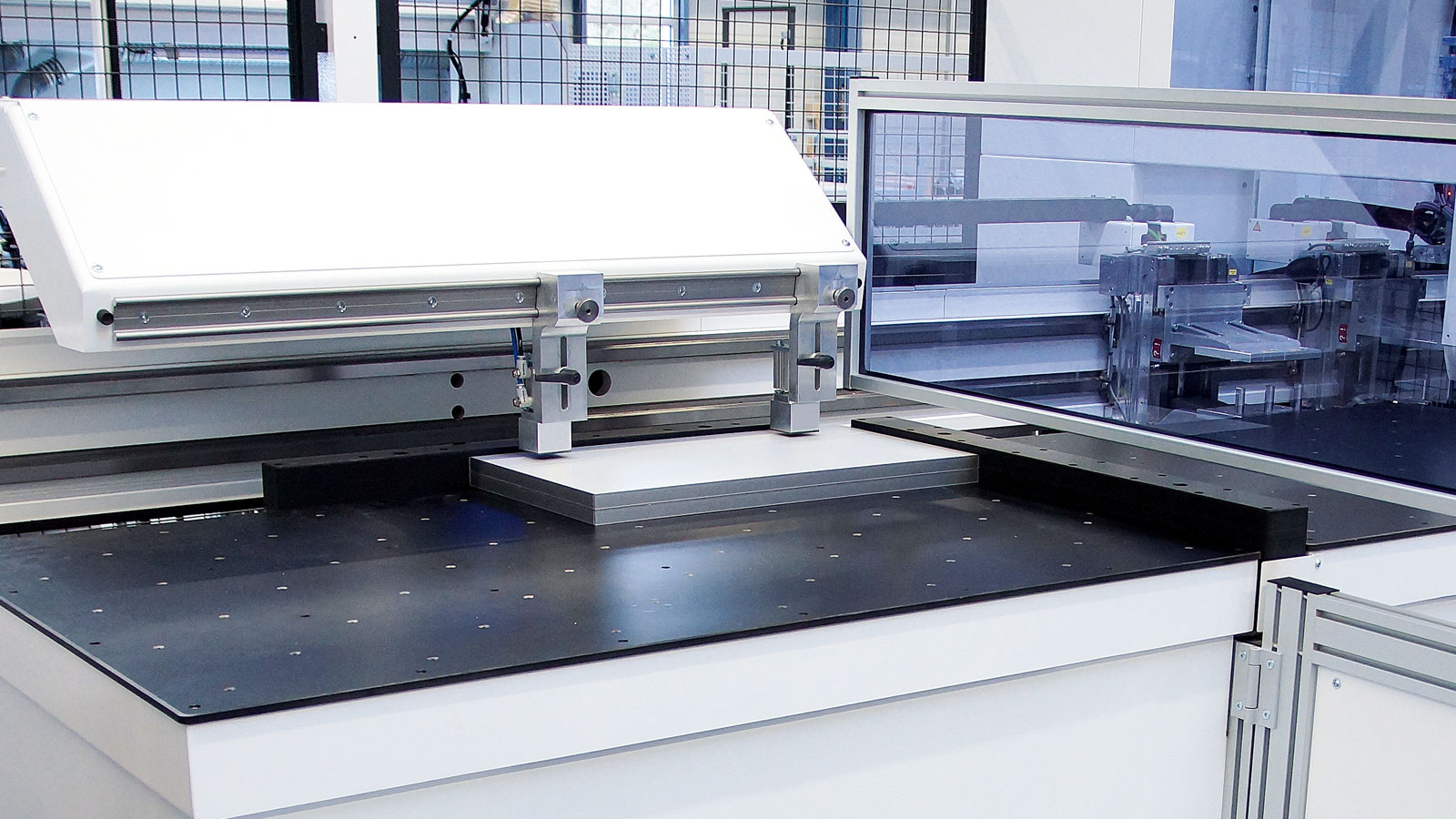

The DRILLTEQ H-600 has impressed by speed and precision – in workpiece handling as well as in processing. Every drill is executed with an extreme repeat accuracy. The same applies to routing and grooving operations. The workpiece surfaces are perfectly protected despite extremely high processing speeds. The possibility to process two workpieces simultaneously leads to extreme efficiency and the varied connection possibilities of the machine provide extreme flexibility. The result: CNC-Xtreme.

Highlights

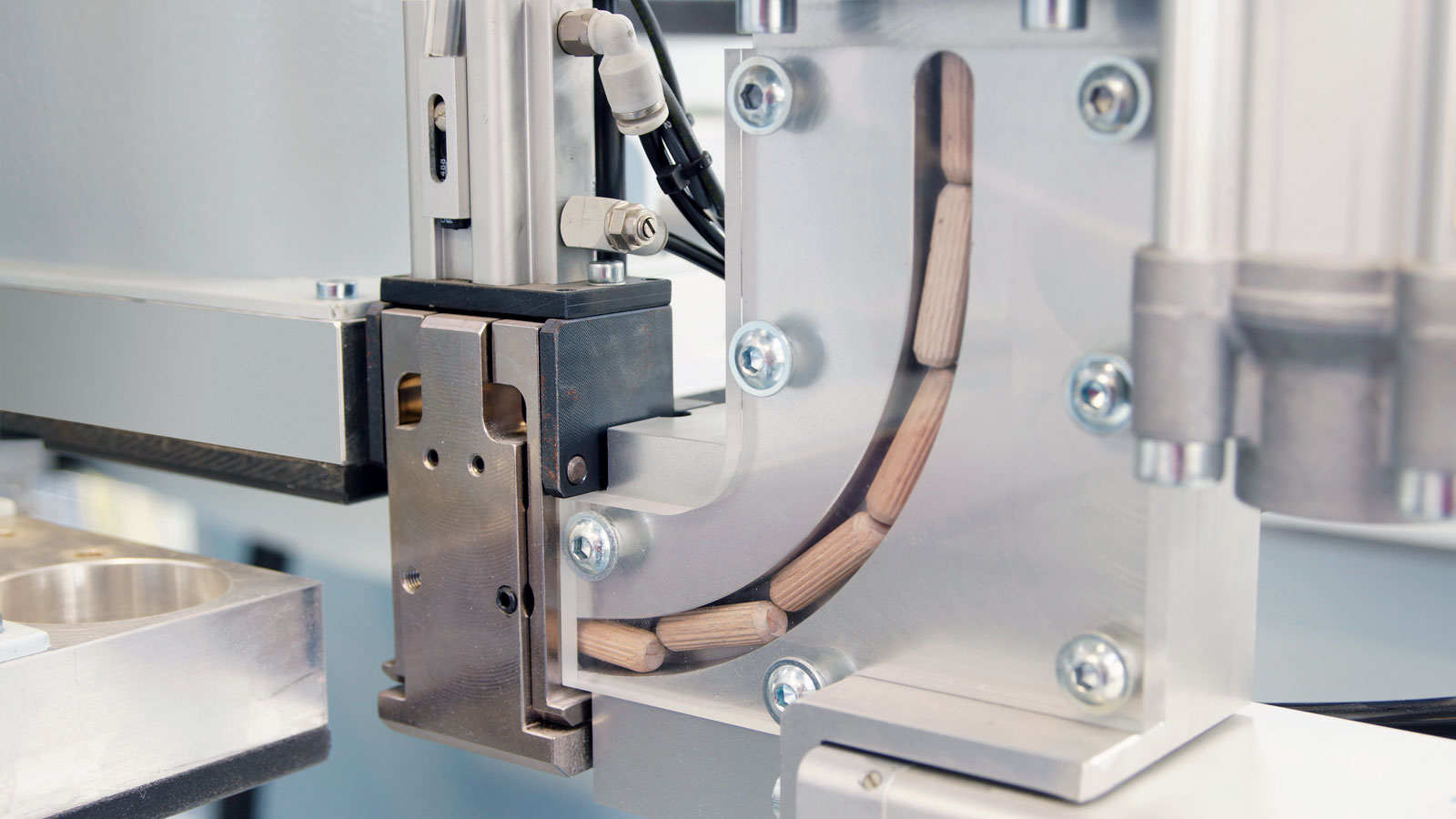

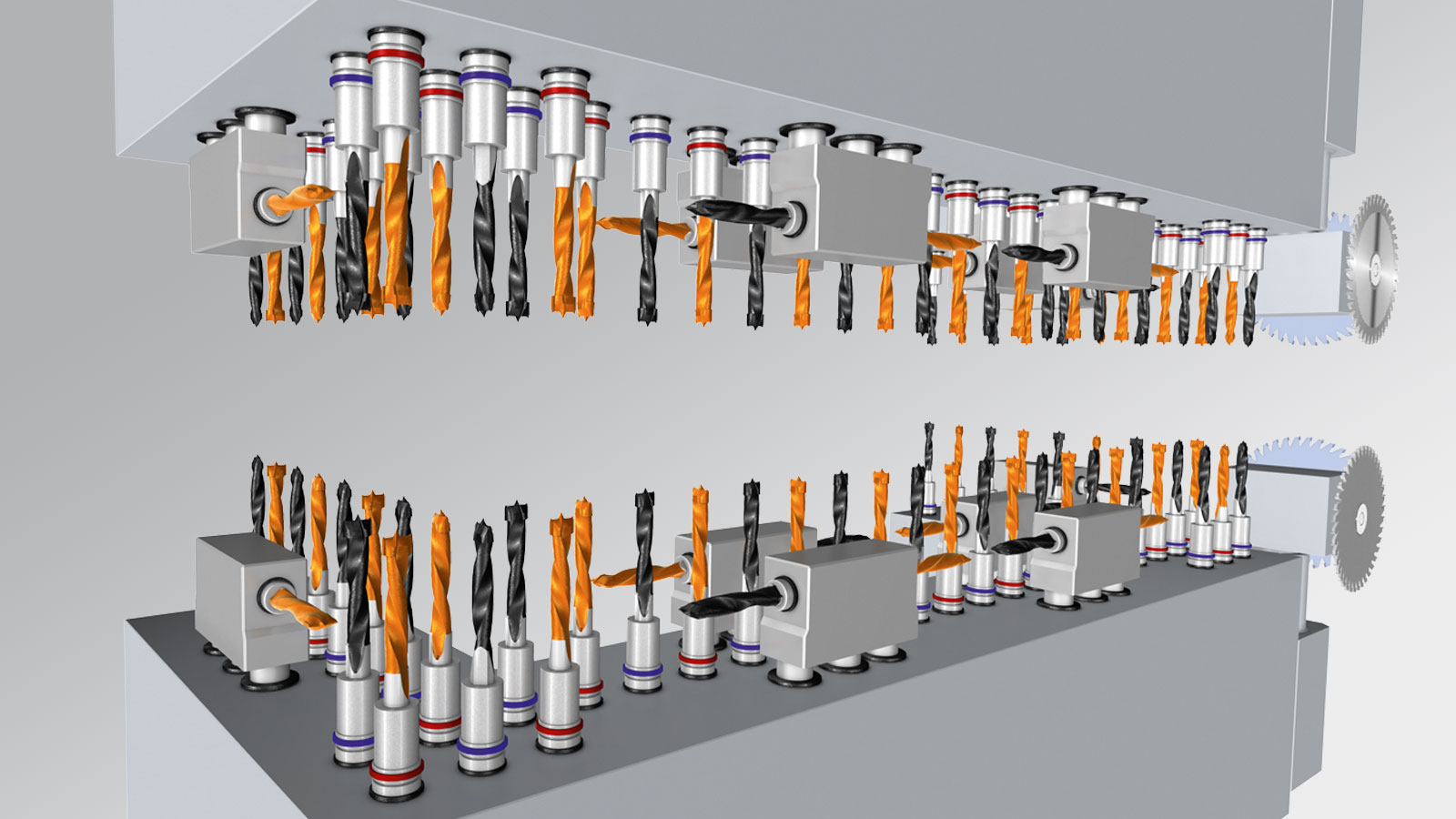

High drilling performance with up to 104 individually retrievable drilling spindles

The unit for processing the 6-side offers complete processing of the workpiece.

Pre-positioning automates the process chain quickly and easily.

Images

Features

-

No set-up times thanks to CNC-controlled collet system

-

Processing on the zero edge thanks to split pressure table beam

-

Always exactly the same drilling depth thanks to automatic spindle clamping

-

"The simple way": If required, the operator has quick and easy access to the processing units for cleaning and maintenance tasks

-

TBO system© protects the workpiece surface

-

Optimum, gentle workpiece guidance thanks to Smooth-Pressure-System©

Technical Data

| DRILLTEQ H-600 | |

|---|---|

| Workpiece feeding dimensions [mm] | 2.500 x 1.300 |

| Workpiece dimensions [mm] | 2.500 x 1.000 |

| Travel range of the X - Y - Z-axis [m/min] | 138 - 80 - 50 |

| Compressed air connection [inch] | 1 |

| Compressed air required [bar] | 7 |

| Dust extraction port [mm] | 2x Ø 280 |

| Dust extraction volume [m³/h] | min. 2x 4.450 |

| Electrical power – total connection load [kW] | 19,5 |

| Total machine weight [kg] | ca. 5.500 |

(Previous product name: CNC-Processing Center BHX 500er Baureihe)

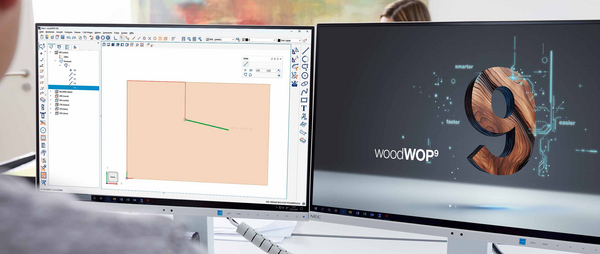

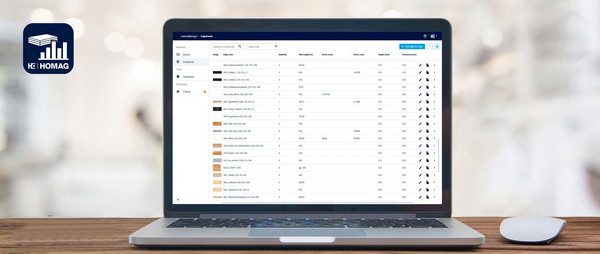

Software

Here's how your colleagues produce

Brochures