Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

WEINMANN Assembly Tables Butterfly turning table

WEINMANN Assembly Tables Butterfly turning table

Turning elements in a single movement

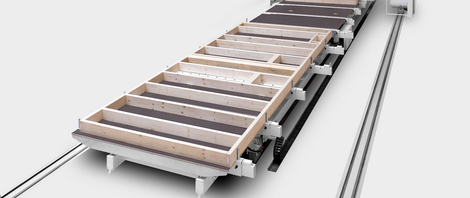

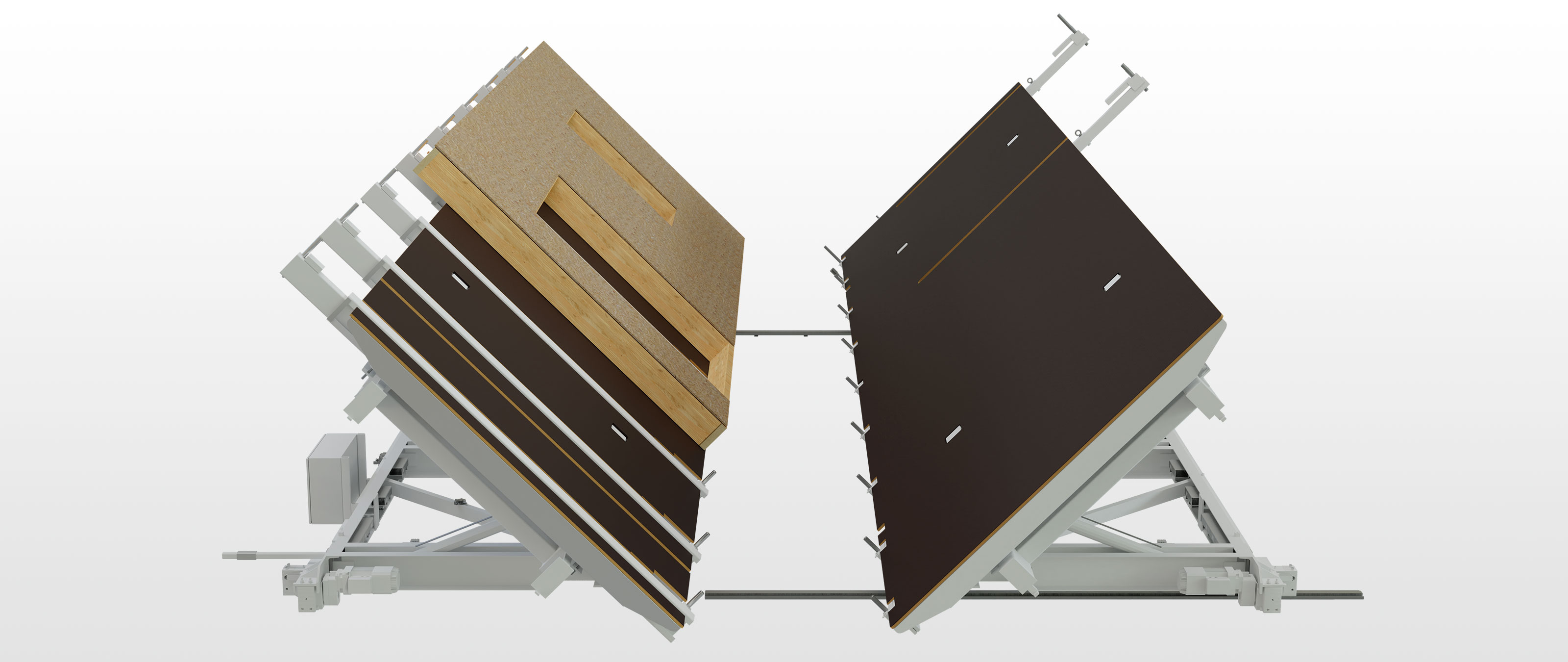

The WEINMANN butterfly turning table offers the ideal solution for turning your elements, allowing you to process both sides. Once the first side has been processed, the element is transferred to the second assembly table where it is completed.

Highlights

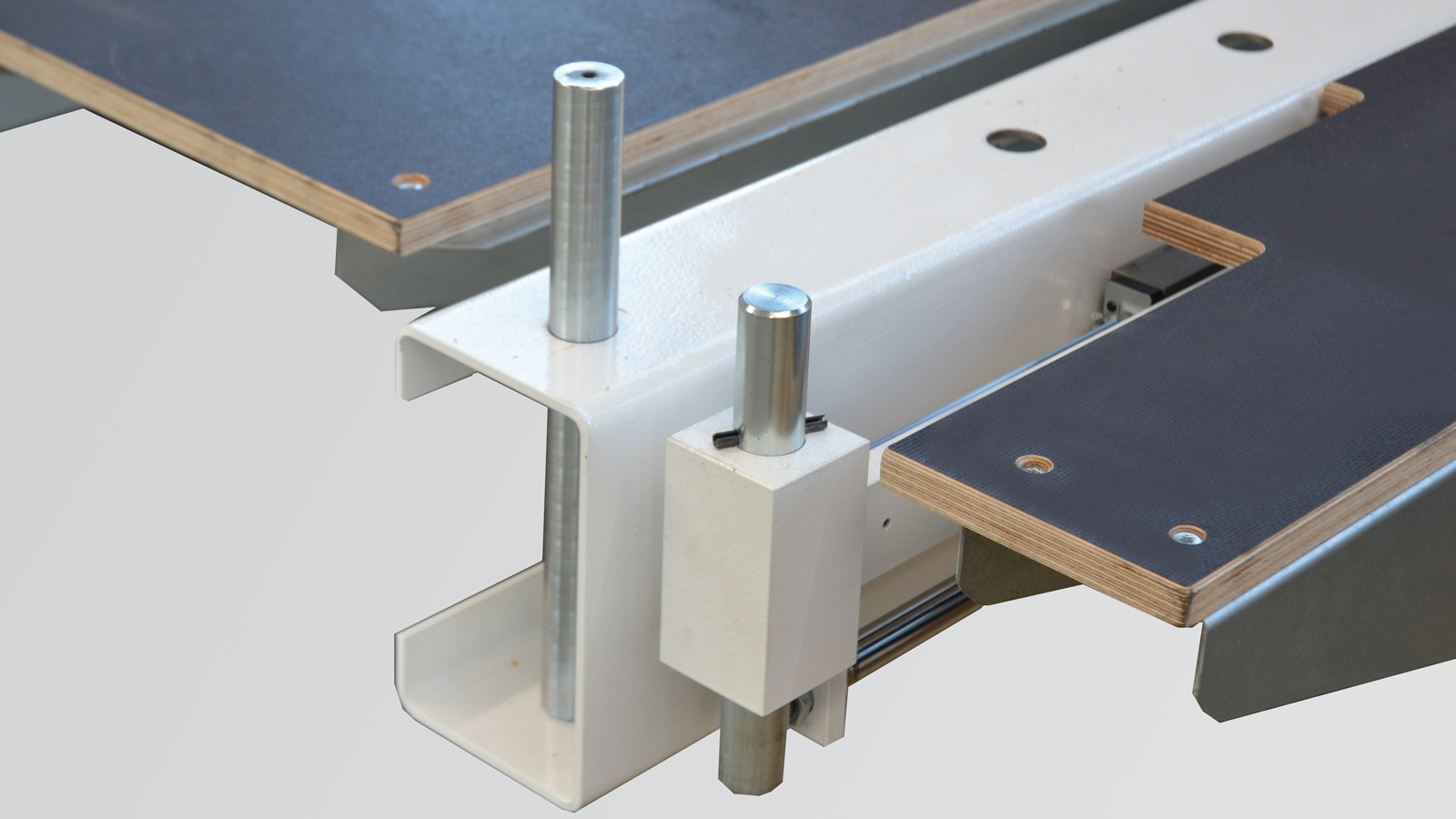

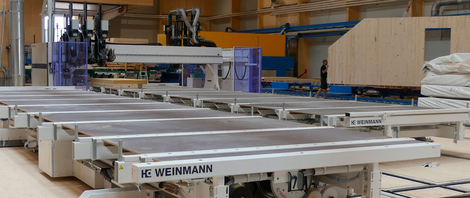

Perfect pairing: The quick and easy turning process with two tables is supported by sensor technology.

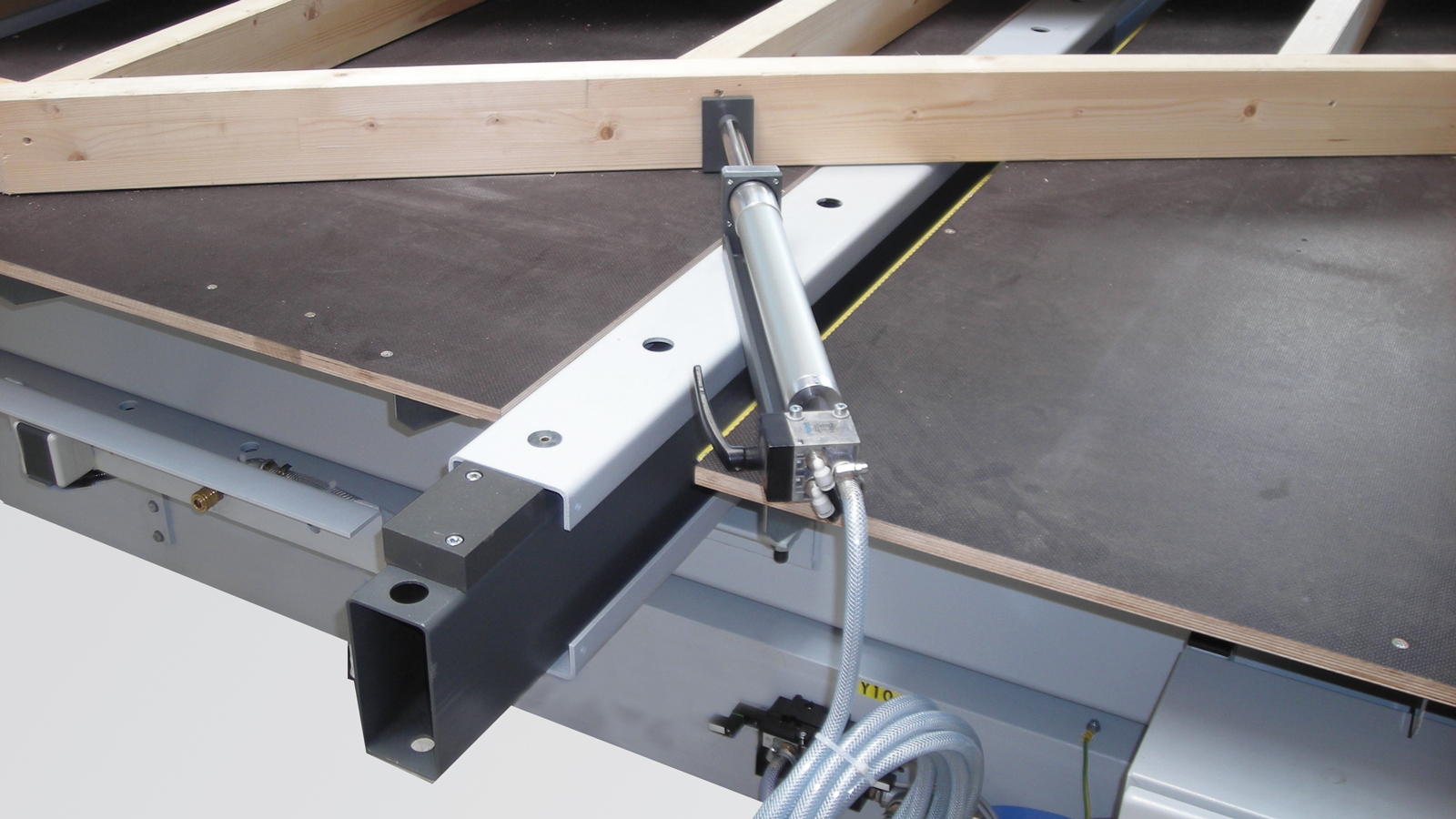

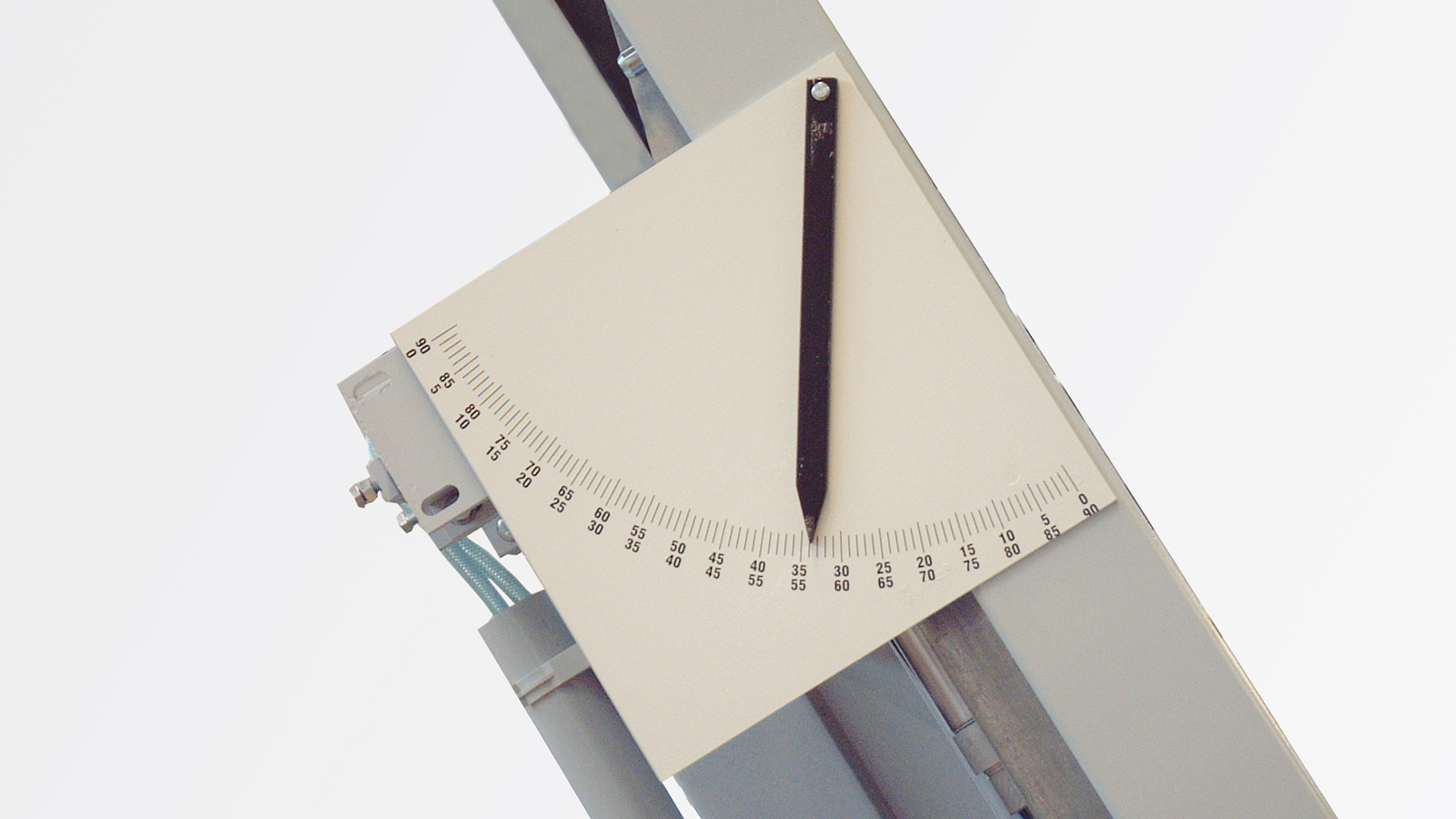

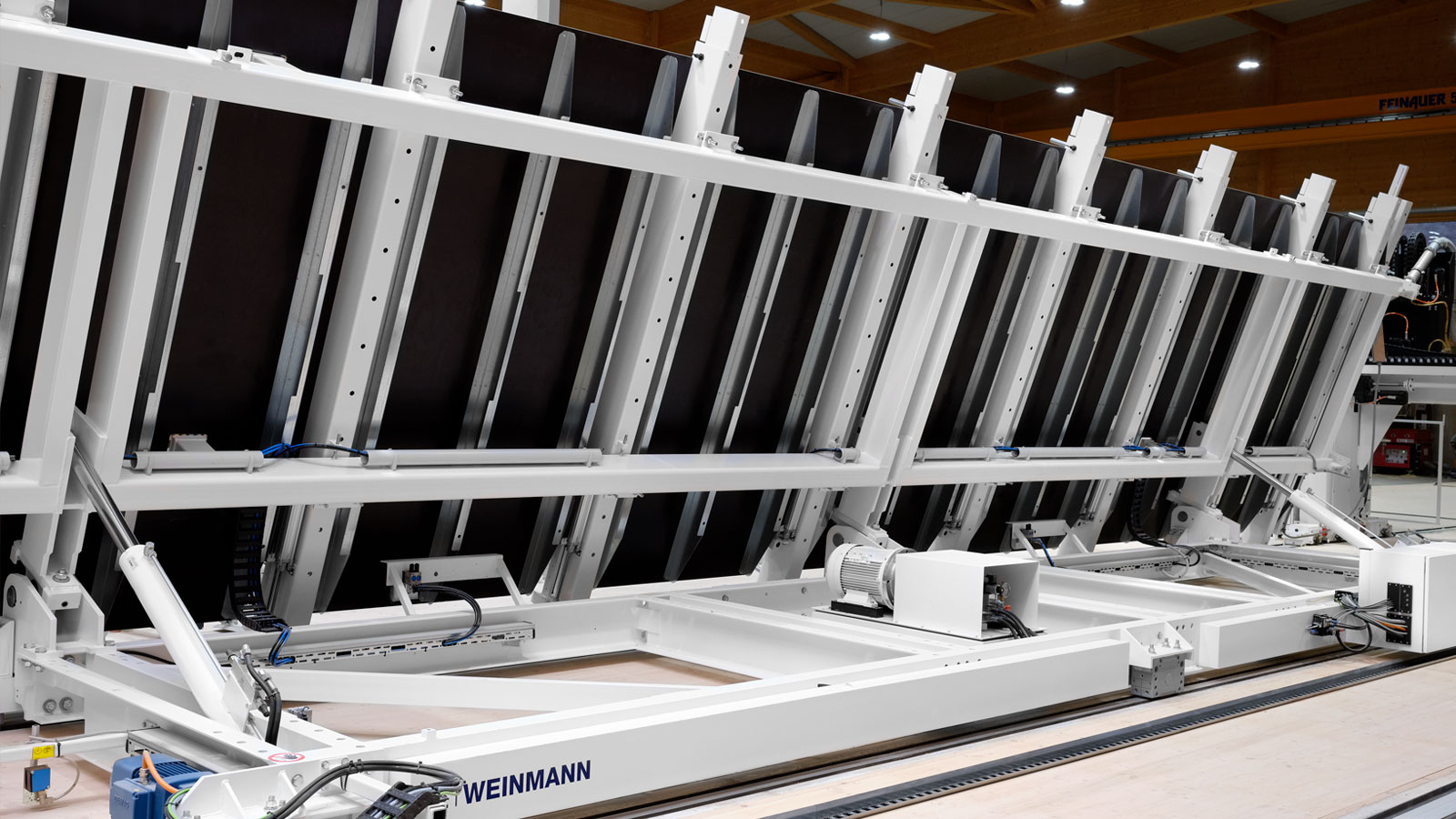

Safe and secure: The hydraulic tilt function enables elements to be turned safely without damaging the workpieces and without use of an overhead crane.

Versatility on the go: The two assembly tables can be positioned perfectly using the integrated running gear to allow simultaneous work on both tables.

Images

Features

-

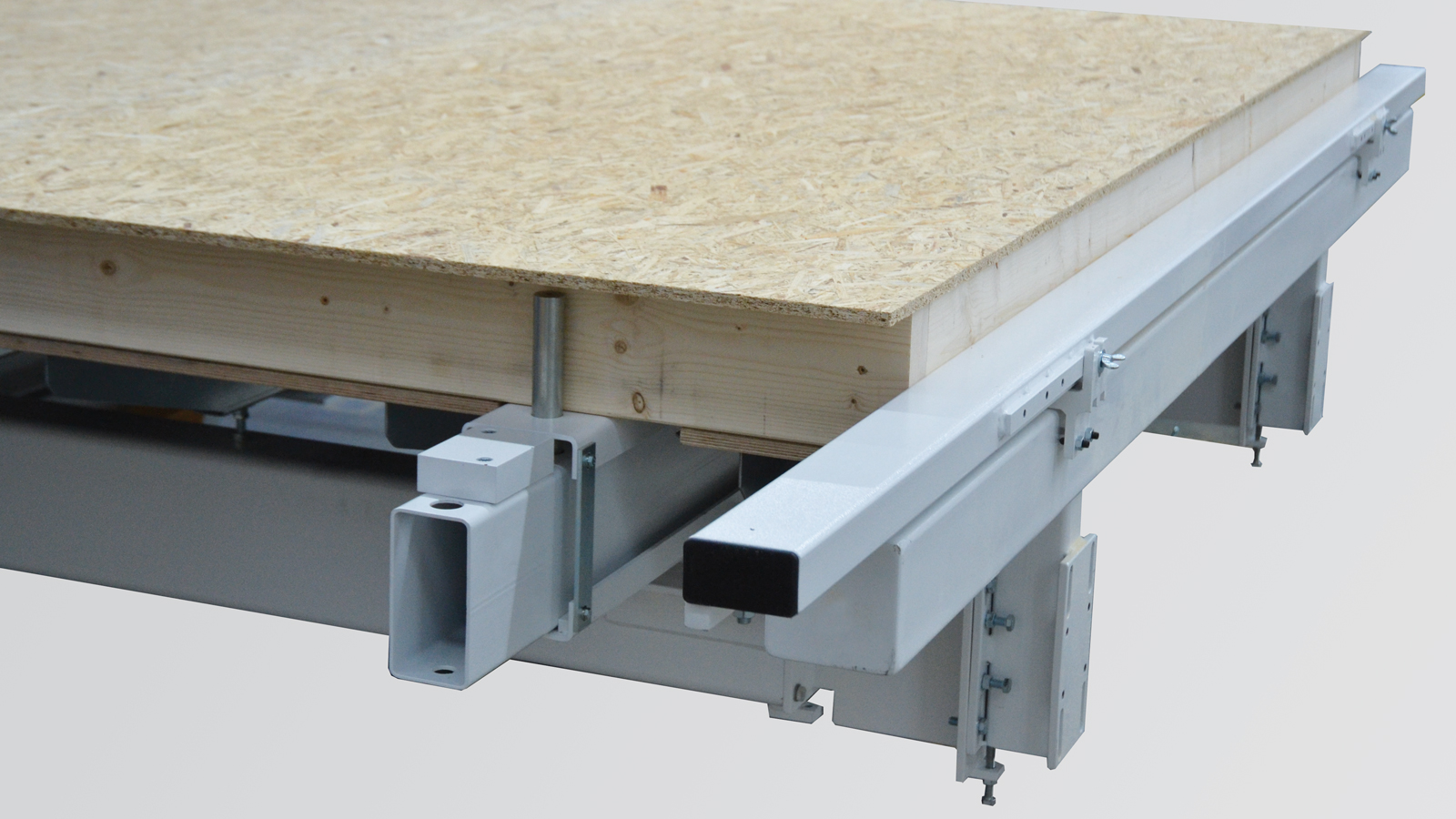

Butterfly turning table consisting of two assembly tables to enable efficient work in parallel on two tables

-

The frame work and the first element side are completed on the first assembly table and transferred to the second table

-

The two assembly tables face one another during the tilting operation and the element is transferred from table 1 to table 2

-

Sufficient space to enable work on both assembly tables, as the tables can be moved into different positions

-

Robust and durable for heavy elements use due to its stable design

Technical Data

| Processing height [mm] | 730 |

| Clamping range [mm] | 400 - 3,800 |

| Element length [m] | 1.5 - 12 |

| Element weight [t] | 3.5 up to 5 [t] possible as an option |

All technical data are without engagement!