WEINMANN solutions for timber construction

WEINMANN presents itself at LIGNA as a comprehensive service provider for timber construction companies. The main topic of discussion at the stand is the industry's current situation and its challenges for the future. This is precisely why WEINMANN has extended its range of services and, in addition to flexible machine technology, now offers integrated solutions — and a partnership far beyond pure manufacturing.

Timber construction has become extremely popular. Order books are still full, skilled workers and material are in demand and the market environment is dynamic. In addition to existing trends such as multi-story and modular construction, new market trends are emerging, such as the energy-efficient renovation of existing buildings and hybrid construction. The requirements in timber construction are very diverse since customer requirements are highly individual. A wide variety of wall structures, materials and element sizes are the norm. When manufacturing wall, roof and ceiling elements, it is therefore all the more important to work with machine technology that can be used flexibly.

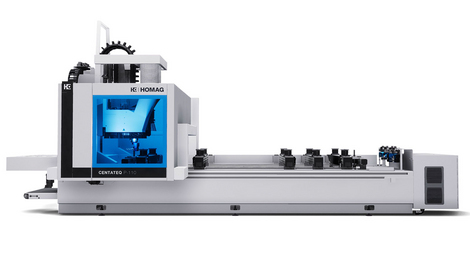

Thanks to its modern machines and systems, WEINMANN has extensive expert knowledge along the entire process chain, from beam processing through the creation of frame works and elements to material handling. With this knowledge, WEINMANN can advise and accompany its customers optimally along the current market trends and beyond.

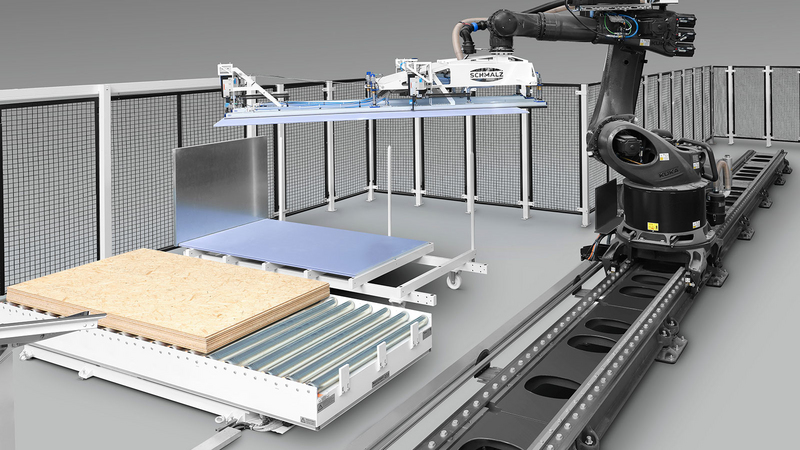

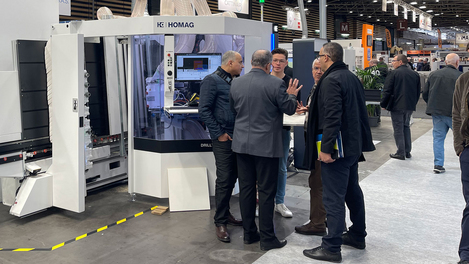

Highly efficient production with robots and multifunction bridges

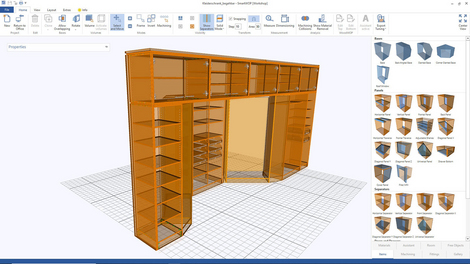

At LIGNA, WEINMANN will be presenting a highly automated and collaborative production cell. The FEEDBOT W-500 robot automatically places panels on the framework. In conjunction with the new WALLTEQ M-300 multifunction bridge, this creates a flexible and autonomous production cell. The robot and multifunction bridge operate in parallel. The robot removes both full-format and cut panels from the unprocessed material stack fully automatically, aligns them, deposits them with a high level of precision and, if required, fixes them in place on the framework.

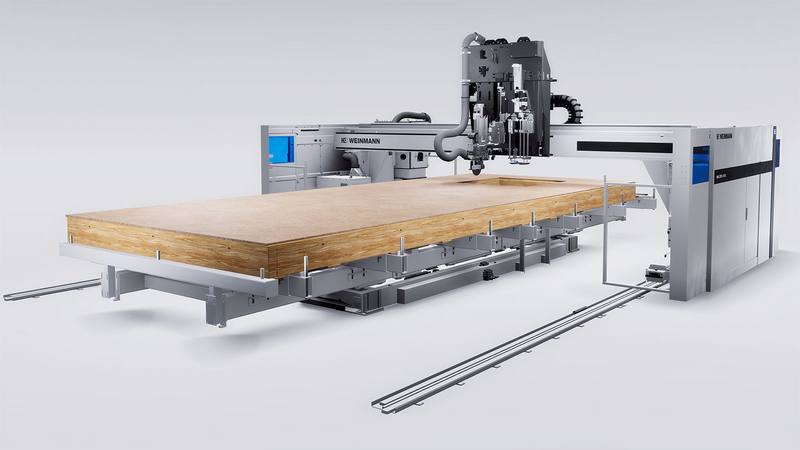

Flexible and profitable production of small quantities

The new WALLTEQ M-300 is ideally tailored to the needs of woodworking shops and meets the increasing requirements with regard to prefabrication and element construction. A sawing unit and a marker can be inserted manually via an HSK interface on the processing spindle. In particular, processing soft wood fiber insulation panels is more efficient thanks to the sawing unit and the optimized suction unit. The increased process flexibility is particularly useful for woodworking shops with a wide product portfolio ranging from classic new buildings to producing elements for serial renovation. Wall, roof and ceiling elements can be processed efficiently.

Partnership far beyond pure manufacturing

However, all technical issues aside, almost every visitor to the trade fair will be faced, sooner or later, with the question of how to position their company for the future. WEINMANN provides solutions for this too: consulting, automation, service and training and further education opportunities for employees. Everything connected and from a single source — a decisive advantage.

The A to Z for your timber framing needs

The motto at the trade fair—"The A to Z for your timber framing needs"—is therefore a real promise and includes everything that lies in between. For example, I for investment. WEINMANN provides holistic advice from the perspective of its customers on what it is worth investing in, whether it's employee training, redesigning work processes or individually tailored technical solutions. This goes hand in hand with long-lasting quality, financing options, swift spare parts supply, an efficient e-shop as the first point of contact and much more.

Another key value proposition from WEINMANN puts the focus on employees — specifically, the employees of its customers. The WEINMANN training department offers a wide range of services for qualification and further training. These include training courses for machines, systems or software as well as continuous further training. Ergonomically comfortable workplaces also help to keep valuable specialists in the company.

An all-round partner for timber construction

The foundation for all this is “P” for partnership. WEINMANN is already at the customer's side in the planning phase. From the outset, WEINMANN examines the initial situation together with customers, analyzes the requirements and, from there, develops solutions that are individually tailored to each business. However, the partnership does not end with the purchase of the system — after all, the aim is to shape a successful future together.