HOMAG presents the new feature of the ControllerMES production control system at LIGNA

ControllerMES: New automation modules accelerate work preparation and logistics processes/transparency on all end devices with HTML5 dashboards.

At LIGNA, HOMAG will be presenting two new ControllerMES modules for further automation of central production processes: Automated generation of cutting batches and automatic, effective component stacking. In addition, it is now possible to monitor production performance on all end devices via HTML5 dashboards.

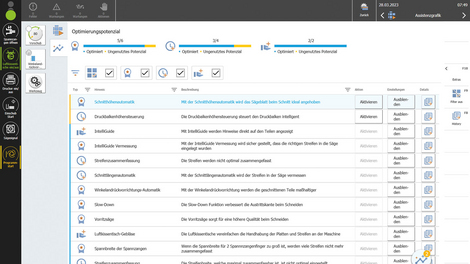

The "automatic batch formation" brings jobs into production more quickly

An efficient new feature of the ControllerMES is the automatic batch formation. Based on defined rules, the software now enables the optimal, automatically controlled formation of cutting batches. For employees in work preparation, this reduces the effort involved to process monitoring. Manual corrections are possible at any time if required. Initial experience has shown that automatic batch formation can reduce planning effort in work preparation by up to 70 percent. This not only saves manufacturers time and material, they also benefit from optimized production processes.

The optimum cutting batch is determined individually, taking into account upstream and downstream production processes. The underlying set of rules also contains a prioritization for handling optimization results. This enables targeted optimization of post-production, for example. ControllerMES creates end-to-end transparency about the processes and the progress of the optimization.

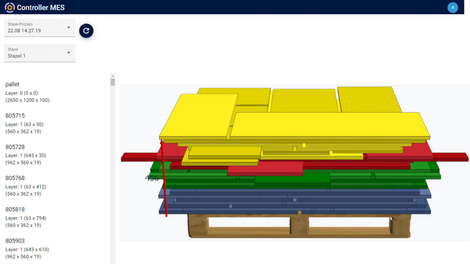

No more time spent searching for components thanks to efficient stack formation

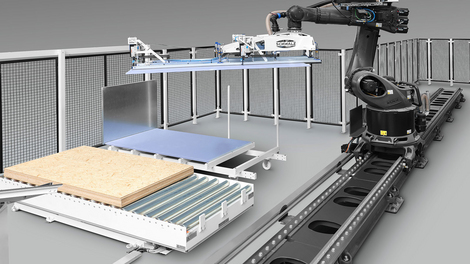

With the new automatic stack formation, components can be optimally arranged on a stack in a stable way. This offers process reliability: there are no incorrect parts in the stack and every stack transport is used efficiently. Thanks to the logically arranged component stacks, logistics movements can be reduced, as well as the space requirement in the buffer and storage.

Automatic stack formation takes into account individual stack configurations such as the base area, the maximum height, the stability factor or the grouping within a stack. After configuration, ControllerMES transfers the stack layout to the sorter magazine with a robot or to a gantry that piles up the stack.

Transparency over relevant production KPIs on all end devices

A further innovation can be found in the configurable HTML5 dashboard, which provides an insight into production performance — on any device. The dashboard can be created individually using production KPIs. The modular structure makes it easier to configure the dashboard.

In addition to live production data, the production dashboard can also display aggregated and calculated values from historical data, such as the number of confirmations or activity and progress displays. A wide range of visual evaluation formats (graphs, tables, etc.) make it easier to keep track of current and past production events.