HOMAG Panel Dividing: Name changes in the panel saw and storage technology sector

In addition to new machine and software solutions, HOMAG Plattenaufteiltechnik is presenting a completely revised naming convention. This is intended to ensure that product classifications and expansion levels can be understood even faster and more selectively. In future, it will be easier to derive important information for individual categorization from the name than before.

- All single and lifting table saws will be given the letter code "S" — e.g. SAWTEQ S-300

- All angular saws will be given the letter code "A" — e.g. SAWTEQ A-300

- All lifting table saws will also be given a "10" in the name — e.g. SAWTEQ S-310 OR SAWTEQ A-310

- All area storage systems will be given the letter code "P" — e.g. STORETEQ P-500

- The STORETEQ S-200 storage system will become the STORETEQ P-300 storage system

- Portfolio expansion: Storage with two levels

- Storage systems with panels only on the second level will be given a "10" in the name — e.g. STORETEQ P-510

- Storage systems with panels on both levels will be given a "20" in the name — e.g. STORETEQ P-520

- Portfolio expansion: HOMAG STORETEQ F-100 single-axis feeder

The SAWTEQ S-300 panel saw "saws new standards"

At this year's LIGNA, HOMAG will be presenting the new SAWTEQ S-300 series for the first time, with significant and innovative new features. The cutting solution combines performance, speed and reliable technology with intelligence and digital, self-learning functions. This is reflected, among other things, in an increased performance level as a result of an improved sawing process and optimized processes with reduced energy consumption. Machine operation is also being rethought and, thanks to clear working positions, the way the operator works with the saw control system is even more flexible and ergonomic. The intelliGuide Classic operator assistance system— which is now included as standard—supplements these optimizations and guides the operator through the cutting process safely and intuitively using LED signals. In addition, quickTip, a new feature within the saw control system, ensures that the machine is set optimally — a further step toward intelligent machine control. The focus is also still on cutting quality. Along with materialManager Advanced, which automatically specifies optimal saw parameters, the machine is equipped with the new toleranceCheck, which uses sensors to detect the dimensional accuracy of the workpieces and transparently reports this back to the machine operator. Good to know: The new SAWTEQ S-300 is ready for function+.

The benefits at a glance:

- Unrivalled convenience as standard: With the new control panel with an additional position on the pressure beam and intelliGuide, HOMAG guarantees the most intuitive and convenient operation on the market.

- Performance is still an asset: HOMAG has increased performance again by up to 20% thanks to optimized and better coordinated sequences in the cutting cycle — especially for machines with Power Concept and storage control connection.

- Sustainable sawing: The optimized chip guide reduces the required suction power by up to 12% and extends the tool life. In addition, cutting optimization solutions such as Cut Rite and the increase in performance, while maintaining the same level of energy consumption, contribute to increasing global sustainability.

- Ergonomic machine operation and maintenance: Improved tool change area incl. flange storage reduces waiting times and increases ergonomics.

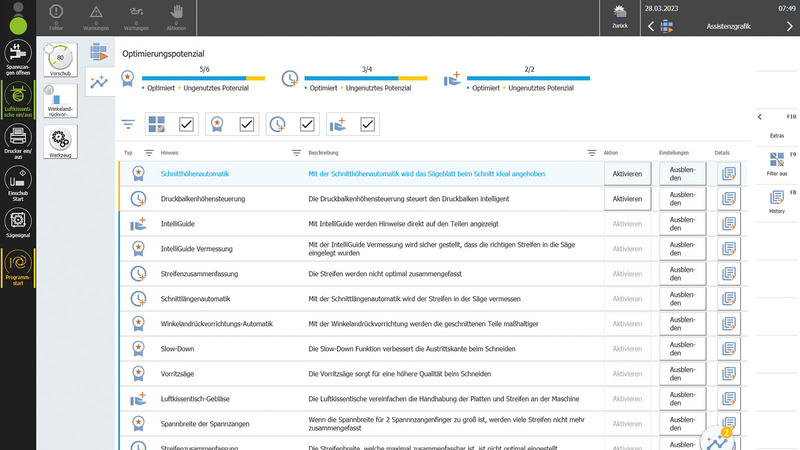

quickTip — The assistant for optimal use of the machine functions

quickTip is a new assistance function integrated into the HOMAG saw control system for maximum quality, operator comfort and performance. It supports machine operators by providing recommendations for optimal utilization of functions directly at the saw. The advantage is that the functions and parameters can be activated centrally at one single point in CADmatic — this simplifies work, ensures smooth processes and a uniformly high output.

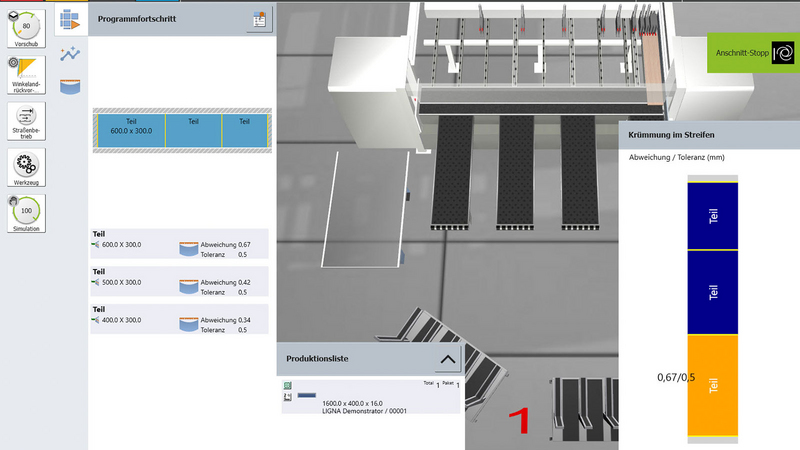

Integrated tolerance measurement: toleranceCheck for high-precision cutting

With the innovative toleranceCheck, you can continuously ensure the individual dimensional and angular accuracy that you require of your parts — even with stress-prone material. At the heart of the technology is a sensor system directly at the right-angled fence that helps the machine operator to see whether the individual parts are within the required dimensional tolerance they have specified even before the cross cut. This gives the operator the opportunity to react in case any changes need to be made. But even if the parts are within the tolerance, the label immediately shows which side is best suited as a reference edge for further processing, e.g. on the edge bander or CNC. The end-to-end quality assurance therefore increases the process reliability of the subsequent processes and creates unprecedented transparency regarding the panel quality. Good to know: toleranceCheck together with the stress elimination cut forms an attractive quality package, ensuring the best quality, minimal waste and efficient production.

function+

Successful entrepreneurs know that the perfect machine grows with them. If the requirements change, it adapts. Ideally, at the touch of a button. Previously, this was a futuristic vision; from today it is a reality. With function+, HOMAG is setting standards when it comes to flexibility: Machine functions can be activated in just a few clicks, without a service technician, and in less than 48 hours. Other plus points: Customers only pay for the functions when they are really needed. And if there is still any doubt about whether a particular function is beneficial, no problem: HOMAG offers the option of simply testing functions, completely free of charge and without obligation.

From LIGNA, the following features can be retrofitted to the SAWTEQ S-300 and S-400 series with just a few clicks using function+ if required:

- Cut-outs and stress elimination cuts

- MMR Professional

- Data backup on network drive

- combiTec — if the motorized scoring saw stroke is installed

- intelliGuide Classic — included in the standard version and can be easily activated free of charge and indefinitely via function+

You can also look at all the new features at your leisure in our keynote on Live.HOMAG:

DE: https://live.homag.com/de/plattenaufteilsaegen/keynote-sawteq-s-300-s-400-de

EN: https://live.homag.com/en/panel-dividing-saws/keynote-sawteq-s-300-s-400-en

New storage technology portfolio combines the strengths of automation with intelligent logistics

At LIGNA, HOMAG will be presenting the new, completely revised range of storage technology for the first time. The range covers the requirements of both small woodworking shops as well as large industrial furniture manufacturers. Rapid changes in market conditions that require flexible, efficient and sustainable adjustment were the clear focus of development. The portfolio is being expanded both downward, by the introduction of a HOMAG STORETEQ F-100 single-axis feeder, and upward, with the STORETEQ P-310/P-510 second-level storage system and the STORETEQ P-320/520 double-level storage system — both from the standard version. Processes are significantly optimized primarily as a result of increased reliability, availability and standardized data integration and processing — this is achieved by the consistent use of the powerful, leading woodStore storage software. The second-level and dual-level storage systems also offer optimal utilization of available resources and address the issue of space limitations that exists in many countries as well as increased production site prices.

The benefits at a glance:

- One software solution, all options: The woodStore storage software grows with the business, from a beginner to a high-end user.

- No compromises: The warehouse grows with the needs and requirements of the customers.

- Perfectly coordinated: HOMAG makes optimum use of the space available — without expensive hall extensions.

- Only one contact person: This also simplifies any potential service cases.

- Complete solutions from a single source — including saw, nesting, storage platform and software.

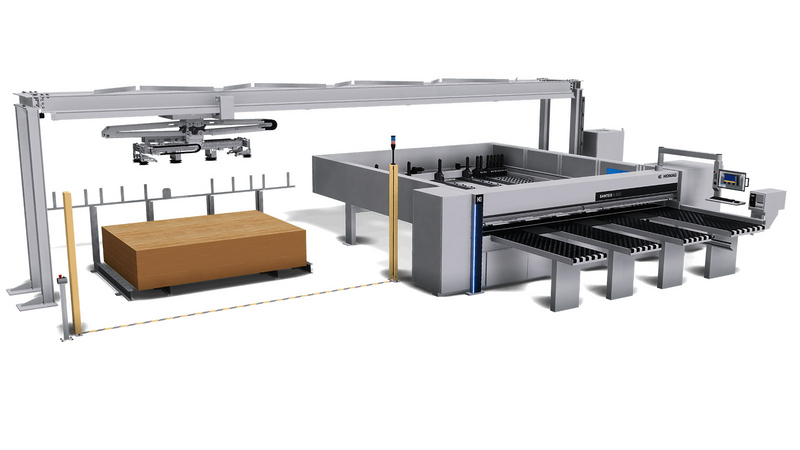

Relief and effectiveness thanks to the new HOMAG STORETEQ F-100 single-axis feeder

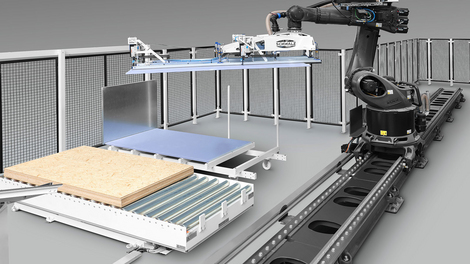

Efficient, ergonomic, material-friendly: The new HOMAG STORETEQ F-100 single-axis feeder is an asset to every aspect of the production line and it does not take up much space either. Control directly at the saw via woodStore is particularly intuitive and simple. In conjunction with the optimized SAWTEQ S-200, this creates a complete woodworking shop cell — including convenient offcut management. Using vacuum suction units, the gantry fetches the next panel from the stacking position adjacent to or behind the saw, turns the material if needed, and then places it in the saw, all on a just-in-time basis. All fully automatically. At LIGNA, automatic panel handling can be experienced live with the STORETEQ F-100 on the SAWTEQ S-200.

The benefits at a glance:

- Accelerated feed: The integrated complete solution leads to significantly higher saw performance. Additional benefit: Less time for sawing means more time for other value-adding activities.

- Fully automatic panel handling: A continuous process increases productivity and saves time.

- Optimized transport: The single-axis feeder secures panel quality.

- Fits into any workshop: The space-optimized feeder requires hardly any installation space.

- More ergonomic: The automatic feed makes work easier.

- Standard interface: All machines are already configured and ready for use — without any additional service support.

- Intuitive operation: The single-axis feeder can be operated conveniently from the saw via woodStore.

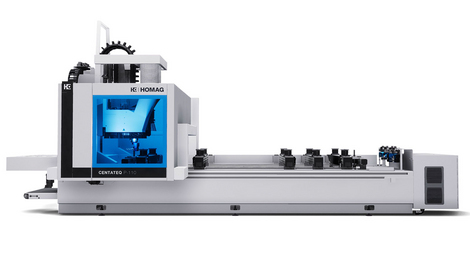

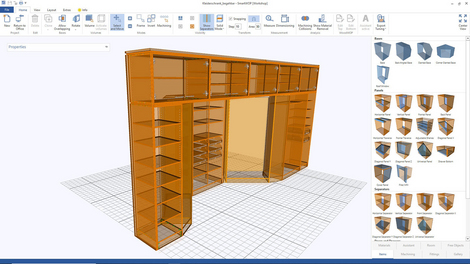

Cleverly combined: STORETEQ P-300 storage system, SAWTEQ S-300 flexTec saw and CENTATEQ N-510 nesting

The combination of storage, saw and nesting is a prime example of the wide range of options for panel processing. The combination is particularly tailored to businesses that process both rectangular parts and free-formed workpieces. The storage system and saw and nesting machines are also equipped to deal with the large variety of materials. The machines interact with each other perfectly thanks to the seamlessly compatible software solutions. An integrated data and material flow is crucial for smooth interaction.

SAWTEQ S-300 flexTec

- Modular design for use in robot mode for highly efficient batch size 1 production with up to 1000 parts per shift or in operator mode with full freedom of action in cutting

- New: The key innovations of the sister model SAWTEQ S-300 are demonstrated in the ergonomics, performance and intelligence

- New: New generation of robots for even more powerful machine processes

- Measuring system cutting quality — "MSQ" for a reliable and objective evaluation of cutting quality

- Production simulation as part of the offer ensures individual transparency and demonstrates the full performance of the unique machine concept

STORETEQ P-300

- New: New, revised platform as the basis for expanding the product portfolio and increasing reliability, flexibility and performance

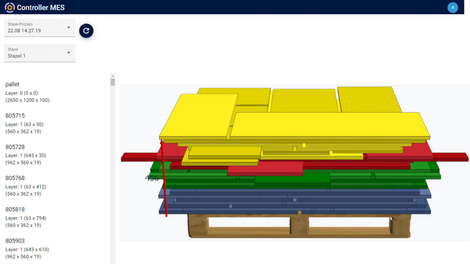

- woodStore 8 — intelligent storage control system equipped with many unique selling points for all solutions based on the new platform

- intelliStore, woodStore Analyzer, flexSort+, multiterminal interface, self-learning cross rail — for efficient and optimized panel management

- New: Protection against power failure can be added as an option

- Low consumption of resources thanks to fully automatic and manual offcut management as configurable standard functions within woodStore 8

CENTATEQ N-510

- Standardized interfaces link the storage system and nesting machine to create an effective production cell.

- The nesting machine is supplied with the appropriate material fully automatically via a workpiece turner. Traffic routes are minimized, utilization is increased and there is a measurable saving in material and time.

- The operator of the production cell can concentrate on the processing — the storage system optimizes the logistics around the nesting machine.