Flooring industry: A production vision

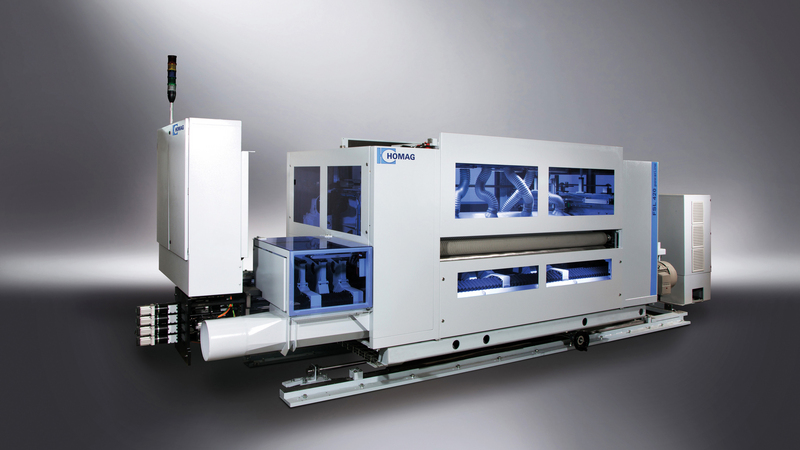

The HOMAG Group has shaped and played a decisive role in the development of plants for flooring manufacture in recent decades, primarily as a system supplier of complete solutions who has now implemented over 1,000 lines.

An article from the magazine Laminat-Magazin, edition 6/2017.

With its processing machines and handling systems for the flooring industry, the HOMAG Group, based in Schopfloch, ranks among the world’s leading technology and machine suppliers in this industry. The company group has shaped and played a decisive role in the development of plants for flooring manufacture in recent decades, primarily as a system supplier of complete solutions who has now implemented over 1,000 lines.

Even in times of digitalization, when it is all about Industry 4.0, networked production and the Smart Factory, the HOMAG Group, by its own assessment, will once again demonstrate its potential in the development of forward-looking technology and re-define the standards of flooring production.

Laminate flooring production is changing

The sudden boom in laminate flooring at the start of the 90s also resulted in increased requirements for machine and production plants. One aspect in particular was key to keeping up with consumer demand – the production speed of the plants.

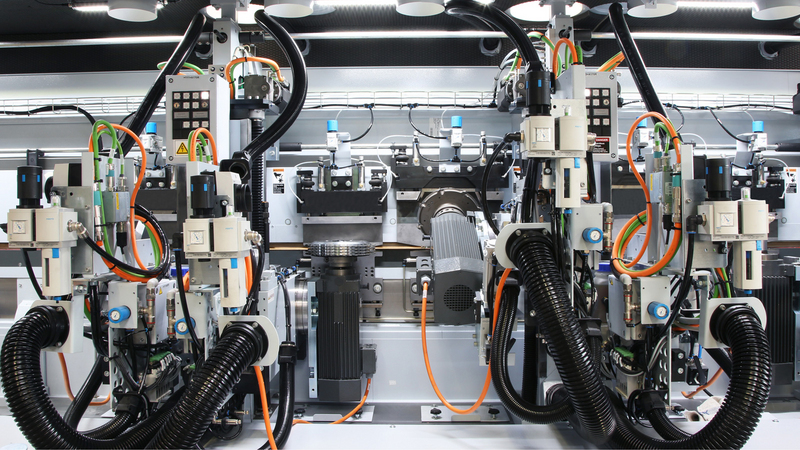

The Schopfloch-based company rose to the challenge and raised the feed rate significantly – from what was then its first profiling machine with a rate of 20 m/min to a rate of 350 m/min today, which corresponds to around 270 planks per minute.

Due to the high level of competition among laminate flooring manufacturers, they are continually launching new and innovative products onto the market. This results in the development of ever more new formats, surfaces and decors – which in turn results in a continual rise in the number of variants. Add to this the fact that consumer buying behavior is becoming more spontaneous and unpredictable, and the logical consequence is that the batch sizes are getting ever smaller.

This development poses huge challenges for laminate manufacturers and their plants, as this contradicts the principles of classic mass production.

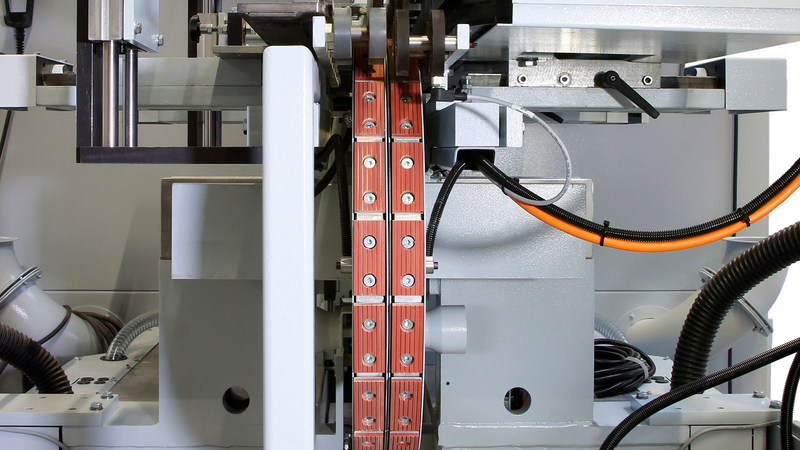

The solution? Flexibility and shorter set-up times. The ability to economically manufacture customer-specific designs in the smallest of batch sizes will soon be a, if not the key, competitive advantage. The buzzwords flexibility and shorter set-up times were and are key aspects when it comes to the development of new machines and technologies. Which is why HOMAG developed a completely new transport chain system for double-end tenoners. This transport chain enables a diverse range of widths to be covered during longitudinal profiling – from a minimum of 90 mm to a maximum of 420 mm.

Thus, with the aid of this chain design, all types, from narrow and standard planks to wide ‘farmhouse style’ planks, can be profiled. This means that almost all common width formats can be created with a single machine – giving manufacturers the ultimate in flexibility. In addition to flexibility, the narrow chain also offers all the other advantages of a high-performance machine with a feed rate of 200 m/min.

A combination of efficiency and precision during sawing

Today flexible and computer-controlled rip saws are used for tasks that used to be predominately tackled by single-shaft multiple-blade saws.

Due to the huge increase in decors and the variety of formats, today the set-up times for a single-shaft multiple-blade saw are no longer acceptable and are simply uneconomical in light of the ever smaller batch sizes.

What is more, the surfaces of the planks and thereby the unfinished panels, change continuously. This affects the pressed chamfer, for example. There is a growing trend for no longer trimming and lacquering the chamfers on the longitudinal and transverse edges and instead stamping these during the manufacture of the unfinished panel with pressing plates.

Dividing such panels poses a huge challenge for rip saws. The separation cuts must be made with great precision to prevent damage to the chamfer and to ensure that enough material remains next to the chamfer for the trimming of a click-profile.

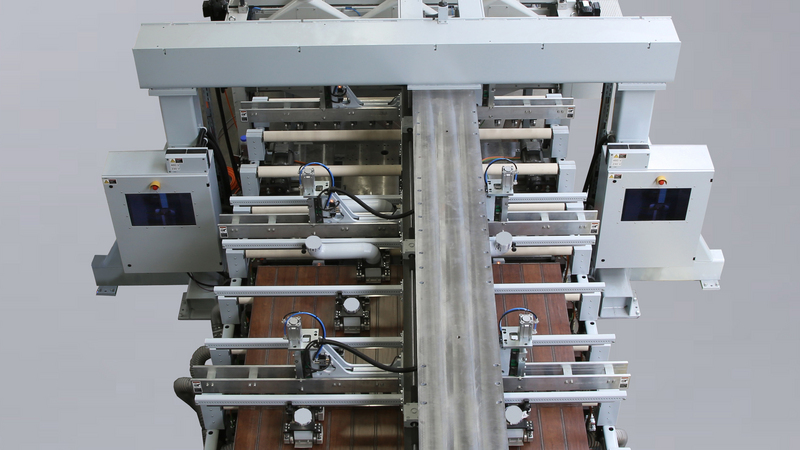

The high-precision FSL 480 rip saw has risen to these challenges. Equipped with proven components from double-end tenoners – such as a rolling magnetic chain, top pressure belt with banded V-belts and individual flexibly adjustable saw units – this machine meets all the requirements.

Flexibility is one aspect – and combined with short set-up times, this will soon be the key factor to success and maintaining a competitive edge.

For many years, the HOMAG Group’s goal has been to keep reducing set-up times further, and they have achieved what they set out to do. The FSL 420 and FSL 480 throughfeed saws can be set to the required sawing dimension and thickness at the touch of a button. The relevant saw units then move to the appropriate position fully automatically. Units that are not needed move to a park position (FSL 420) or simply move out of the working area (FSL 480).

Just like the rip saw, the crosscutting saw can also be automatically set to new part dimensions. It is worth noting that it is not only the saw that offers automatic set-up, but the associated magazine too.

Intelligent position indicators and operation 2.0

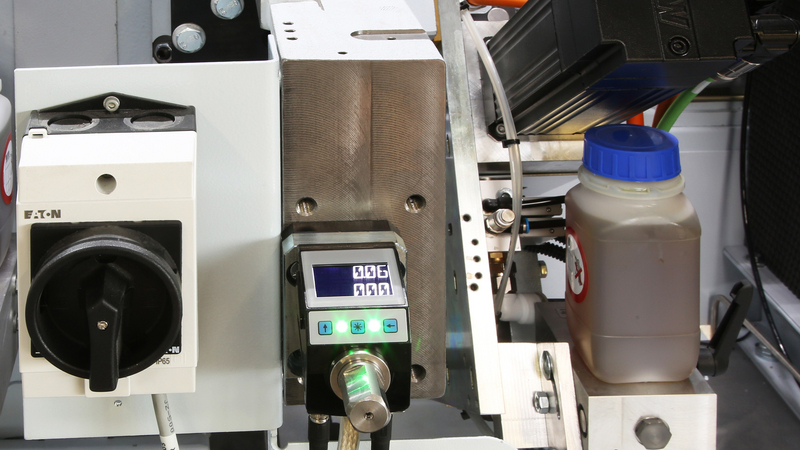

The time required for setting a profile probably leads to the longest machine downtimes during laminate floor production. However, with sophisticated technology, these settings can also be automated. The high-tech version offers fully-automatic adjustment of all processing motors into the specified position – keeping machine downtimes to a minimum, and boosting plant efficiency.

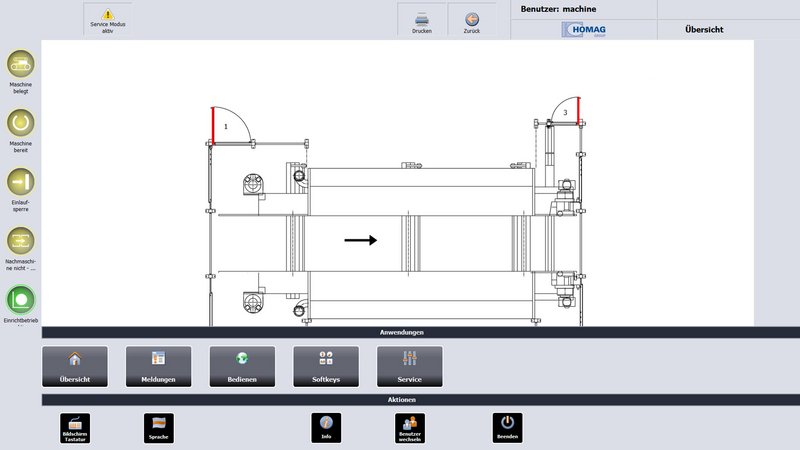

Intelligent position indicators can be used to increase efficiency when it comes to manual positioning of the processing units. The digital position indicator shows the machine operator both the actual and target value of the unit position. The great thing about it is that the operator only needs to select the required product on the control panel and the position indicator will indicate the position in which the unit needs to be set. Then, all that is needed is fine-tuning by means of a gage. The use of these features has a positive effect on the set-up times, it is also a huge help to the machine operator, and incidentally, it also considerably reduces the risk of a costly crash, as the machine only permits release once all the units are in the correct position.

In regard to packaging, the system partners of the HOMAG Group are asked to design the machines to be as flexible as possible. Thus, different package dimensions no longer pose a problem. To save time and money, the packaging plant can also be equipped with servomotors.

The robot has become indispensable for stacking the packages. Its flexibility and exceptionally high availability make it unbeatable for this application. The robot’s gripper tools are designed so they can be flexibly set according to the various package sizes.

As the interface between man and machine, operation is a key part of production – it can make or break an investment. After all, only machine operators who are familiar with all the machine’s functions are able to use it optimally. In regard to operation, the HOMAG Group focuses on two key aspects – ease of use and uniformity. The revolutionary touch operation and the uniform user interface is designed to raise the interest of the machine operator while breaking down barriers. Operation is similar to that of a smartphone or tablet, with gestures such as swipe or zoom. The intuitive and modern operating concept is easy to understand and it is also fun to use.

Another key advantage is the uniformity of the user interface. All machines from Schopfloch are equipped with this operating concept, which makes it easier for operators to also operate other HOMAG machines in the plant.

The next step – a vision of laminate flooring production 4.0

The wide range of laminate flooring products will continue to increase while products become ever more customized. Digital printing technology, which enables customer-specific design requirements to be met, has opened up a whole new dimension in regard to product variety. Previous principles of mass production are no longer compatible with this development. Laminate production is moving toward “mass customization”, i.e., the manufacture of customized products at the cost of mass production. The HOMAG Group is also preparing for the digital age. Machines will become increasingly more intelligent. There will be a significant increase in networking and communication between individual machines. But it is not just communication with one another that plays a role here – it is primarily communication to higher-level manufacturing execution systems, which the Schopfloch-based company already offers in furniture production, that will play a key role in the flooring plants of the future.

The manufacturing execution system is crucial for the production of tomorrow. It coordinates the order sequence and supplies the plant with the material required for the order. The plant adapts itself fully automatically and in the shortest time possible to the specifications of the manufacturing execution system and processes the order. Any deviations from normal are reported immediately.

This is carried out by intelligent components within the stand-alone machines, which monitor and fully control the machining processes. Thus, profile measurement is coupled to the processing units. Even the slightest deviation between the target and actual values is immediately sent to the relevant processing motor, which then corrects itself – during operation. The plant only needs to be stopped if the profile accuracy exceeds a specific tolerance level.

If a worn tool is the cause of the plant stop, the new tool is read in to the system and the relevant data is forwarded to the processing unit, which then re-positions itself based on the actual tool data. All requirements which arise on the plant are reported so that production is not interrupted unnecessarily. If, for example, the next service is due, then this can be taken into account in production planning and carried out in parallel to a scheduled stop.

Thanks to the vast flexibility and shortest possible set-up times, this vision for a flooring plant of the future places the manufacturer in a position to process customer-specific orders in the smallest batch sizes within the shortest possible amount of time.

Source for images: HOMAG Group AG