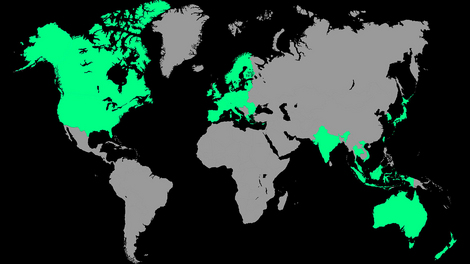

Advanced solutions for CNC processing and drilling technology, from single operation to interlinking in cells.

At HOLZ-HANDWERK 2022, HOMAG will be presenting an extensive selection of machines that already shine individually or that, supplemented by a robot, contribute to the optimum performance increase, for the target group of CNC processing and drilling technology.

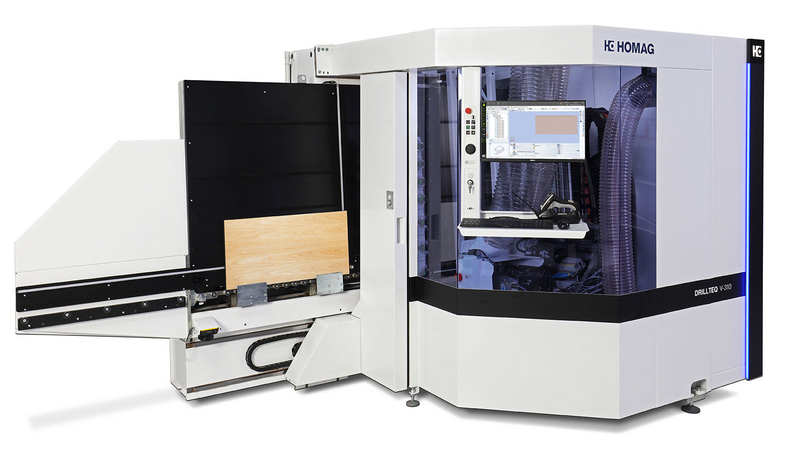

NEW: The Raumwunder — The new DRILLTEQ V-310 vertical CNC processing center.

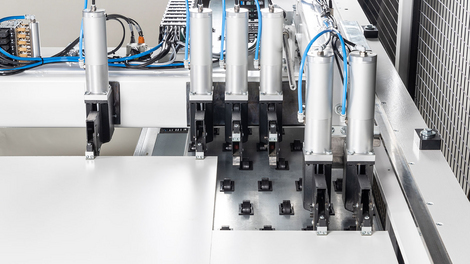

The new DRILLTEQ V-310 vertical CNC processing center, a space-saving masterpiece in the field of cabinet processing, will be presented to the public for the first time. Ergonomics and ease of use were at the heart of the model's development. The new machine is therefore characterized by its wide range of functions in just a small space.

Look forward to a processing center that will take new approaches to accessibility and setup functionality. A selection of up to 45 drilling spindles in a split head configuration and a C axis with a unit interface offer extensive processing options. The improved suction concept and the vacuum-free fixing of the workpieces save energy and costs at the same time.

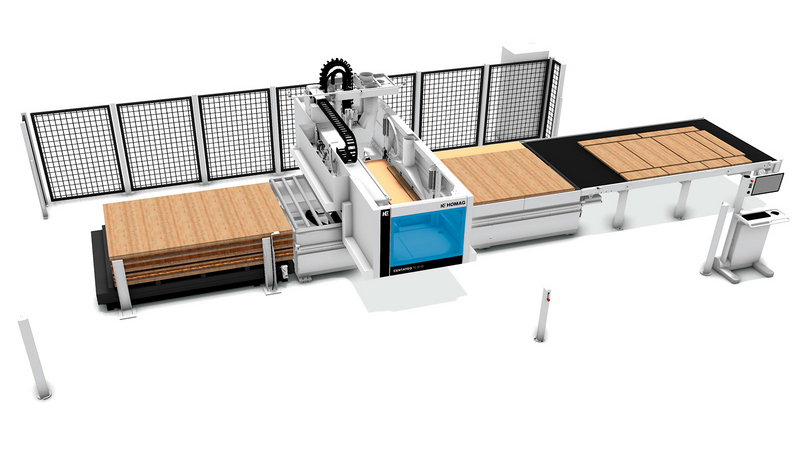

NEW: The CENTATEQ N-510 model. Comprehensive new solutions for working efficiently with maximum flexibility.

At the HOMAG Treff in Herzebrock in November 2021, customers were able to experience the new nesting series live for the first time. This series caters to all demands as well as future requirements — from entry-level woodworking shops through to industrial orientation.

Improved handling and increased output were the clear areas of focus in the development of the new nesting series. Key features include the different table sizes and automation concepts, which are optimally designed for the target groups. The new generation is automated and works in single operation, from three-axis technology to five-axis technology and on table sizes from 1.25 x 2.5 m to 2.1 x 7.4 m — also in half-sized format. The main components are a highly modular, switchable vacuum and air cushion table concept as well as newly designed suction components that have been optimized using CFD flow simulation. There are also innovations in the area of workpiece handling that can be easily expanded via plug-and-play in the modular concept.

The new nesting series is designed and prepared in such a way that additional components such as the label printer, the automatic lifting table or the webbed belt can be easily installed and connected via plug-and-play.

Live in Nuremberg is the CENTATEQ N-510 model, which, in addition to the extensive nesting processing, also enables five-axis processing as it is equipped with the Drive5CS unit. On the one hand, the already well-known serial holes, 8.5-mm grooves for rear walls, light strips and furniture connectors such as dowels, Mini Fix or Cabineo can be processed without any problems. The CENTATEQ N-510 can also deal with miters with a 350-mm saw blade, solid wood components such as stair stringers and door panels without the slightest difficulty. The high-precision stopper systems provide optimum support for the machine, as they can be controlled at different levels depending on the application.

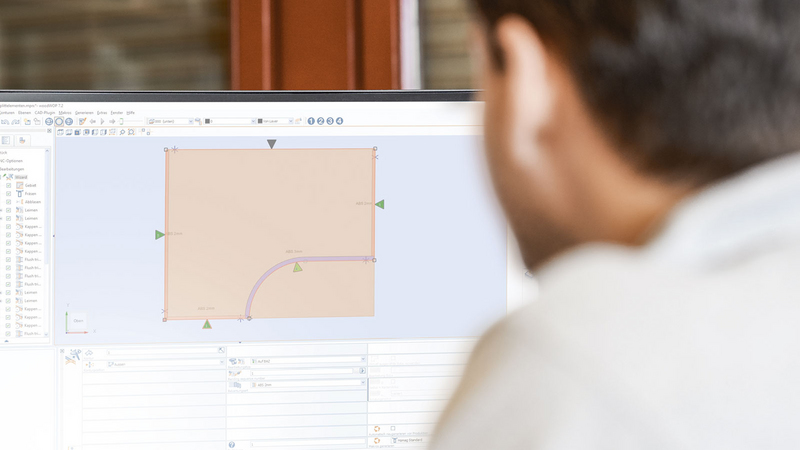

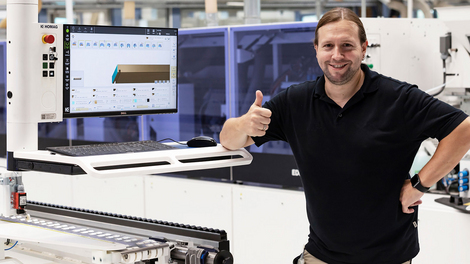

woodWOP 8 software: New functions. Infinite possibilities.

The focus of the new version of woodWOP, which was introduced in fall 2021, is on the innovative large graphics area, which displays the workpiece in three dimensions. The relevant processing parameters can be entered and realistically displayed in the graphic to program trimming and drilling operations and saw cuts quickly and easily. Since the introduction of this new version, users have benefited from these innovative new features.

- The contour assistant provides comprehensive support for beginners when programming non-rectangular workpieces.

- The feature recognition not only detects bore holes but also pockets and grooves in a 3D workpiece model.

- Auxiliary graphics, additional attributes and the form view simplify the operation of extensive variable tables.

- With the new gluing wizard, workpieces for edge banding can be programmed even more efficiently.

- The formula assistant easily defines even highly complex formulas and thus offers further options for advanced users.

To simplify and increase efficiency, tried-and-tested settings can be stored in the CAM plug-in for similar applications.