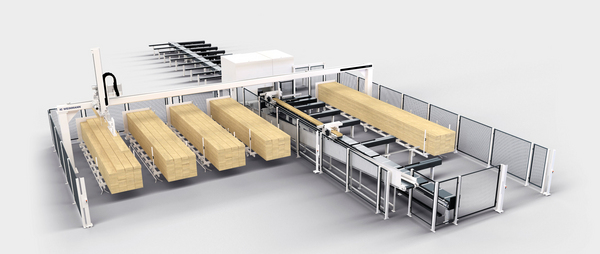

In 2017, the largest and most modern house production facility in Europe was set up at Lindbäcks in Piteå, Sweden. Lindbäcks produces around 3,500 modules per year over an area of 42,000 m². Lindbäcks is a family-owned company, which believes in healthy living and the building of sustainable houses that meets the need of tomorrow.

Founded in 1924, Lindbäcks started as a saw mill. Later Lindbäcks developed to a traditional construction company. Due to a market crisis in 1994, Lindbäcks changed their product portfolio to reach new markets. They started to use timber as a building material and changed the production process to prefabrication. For the past 20 years, all buildings have been produced inside the factory. Lindbäcks has developed an industrial production process for multi-dwelling buildings with the automotive industry as a model. To set the prefabrication degree on an even higher level, in 2017 Lindbäcks invested in the latest technology and accomplished the most modern manufacturing plant in Europe. Ola Magnusson, Project ManagerLindbäcks, tells us more about this project.

Ola, what was the reason to modernize the complete production process?

Ola: The heart of our business is to build industrially and we needed to increase our capacity. Our company vision is to be the first choice for the building market and the customers. Therefore, we need to produce with state-of-the art technology. Thanks to modern technology and lean production, we are now able to produce homes quickly, safely and cost-efficient in our new production facility. With the new production system we are now able to produce 2,600 apartments per year. Our efficient and innovative production method offers best conditions for an efficient production, provides a higher level of security for our employees and saves on material resources through reduced waste.

Can you tell us why you've chosen WEINMANN as your partner?

Ola: We were looking for a production system which fulfills our requirements and helps us to reach our company vision. Therefore we were looking for a partner who understands our needs and was able to transform this to the ideal system for us. With WEINMANN, we had a partner who offered not only the best machine technology; they offered the complete solution for our requirements. Based on our requirements, WEINMANN developed the suitable production system with complete new technologies to meet our requirements.

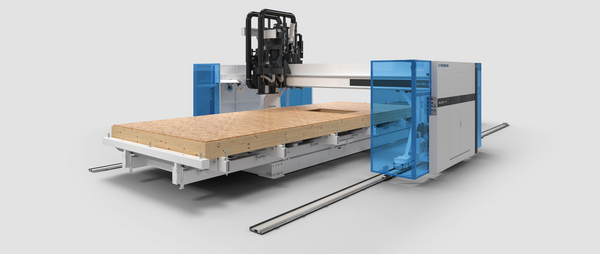

One of the highlight of the production line is the integrated robot. How do you benefit with this technology?

The robot is responsible for inserting the studs in the frame work and is integrated in the frame work station. The robot inserts them in the frame work fully automatically and completes a wall element in less than 7 minutes. The robot - and also the vacuum handling systems - makes the logistic process much easier and offers a good working ergonomic for our employees. The system offers also a high working safety. I think robots will be used more and more for prefabrication.

Why has Lindbäcks focused onmodular constructions and canyou describe some interesting projects?

Ola: We believe modular constructions in wood to be the future way of building high-quality, healthy, affordable homes that are climate-friendly and nice to live in. Industrial production is also the best way to keep a high standard in security and work environment for our employees. We build 2 - 8 floor houses with a variety of rental apartments, condominiums, senior living, student housing, retirement homes and hotels. Modular constructions are also well suitable for adding floors/apartmentsto already existing houses/buildings. For example, we have built a hotel on top of a parking garage in Umeå and student housing on top of a school in Lund. We mainly build for other clients, such as LKAB who are building several new houses up in northern Sweden, Kiruna. The city is moving(!) since LKAB needs to drill for more iron in the grounds of the former location. Another example is Rikshem for whom we build rental apartments and condominiums in different cities in Sweden. We also build in-house projects, both in the purpose to own and administer ourselves such as the rental apartments Tallenin Piteå but also condominiums such as Dagsmejan in Sollentuna that we sell directly to the end customer. Dagsmejan is a project with 203 apartments divided into five houses.

Please give us a short overview about the timber construction market in Sweden.

Ola: The share of timber as a building material in Sweden is high, especially in single-family homes. But the usage of wood is increasing overall, also in multi-story buildings. Since Sweden joined the EU in 1994 it is allowed to build higher than 2-storeys in timber construction. This opens a lot of new possibilities for timber construction. In Sweden, we have a trend to build more apartments instead of singlefamily homes. Apartments offers the people more flexibility in life as an own single family home. And there is also a growing urbanization. People are moving in to the cities. Because the land in the city is expensive and limited, apartments in multistory buildings offers more possibilities. Wood as a building material is an environmentally friendly material that contributes to a healthy living environment and reduces carbon dioxide emissions. Customers are more aware of the usage of material, because they are looking for ecology and sustainability. It is a concern of every person to decrease the own ecological footprint.

Europe's largest and most modern house production facility

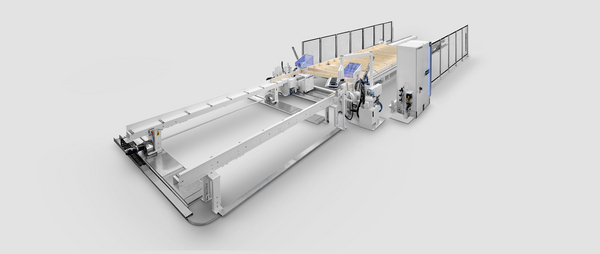

Highlights of the production line:

- Fully automated stud installation with integrated robot

- Fully automated panel placing as well as glueing between both layers

- Fully automated production flow in cycle operation

- Element tables with automated adjustment to the required element width

- Record of process times and following analysis

- Fastening of panels with 4 parallel working nailing pushers; integrated automated coil changer reduces downtimes

- Short processing times: parallel working of 2 multifunction bridges on one element

Ola, thank you for talking to us.

An article from the WEINMANN customer magazine performance, version 18/ 2019. Here you can read the customer magazine performance online.

“With WEINMANN, we had a partner who offered not only the best machine technology; they offered the complete solution for our requirements.”Ola Magnusson, project manager at Lindbäcks

Lindbäcks

Lindbäcks is a family-owned company, which believes in healthy living and the building of sustainable houses that meets the need of tomorrow.

Website