Between Nuremberg and Ingolstadt, just a few kilometers from the Main-Danube Canal, lies Fribertshofen. The village in the Upper Palatinate has a population of just 160. Here, everyone knows each other; here, everyone helps each other; here, Saturday is still a real working day. It‘s also completely normal for people to still be working hard in the early evening. However, it‘s awkward when you then run out of screws or need something sawing, but the nearest hardware store has been closed for hours.

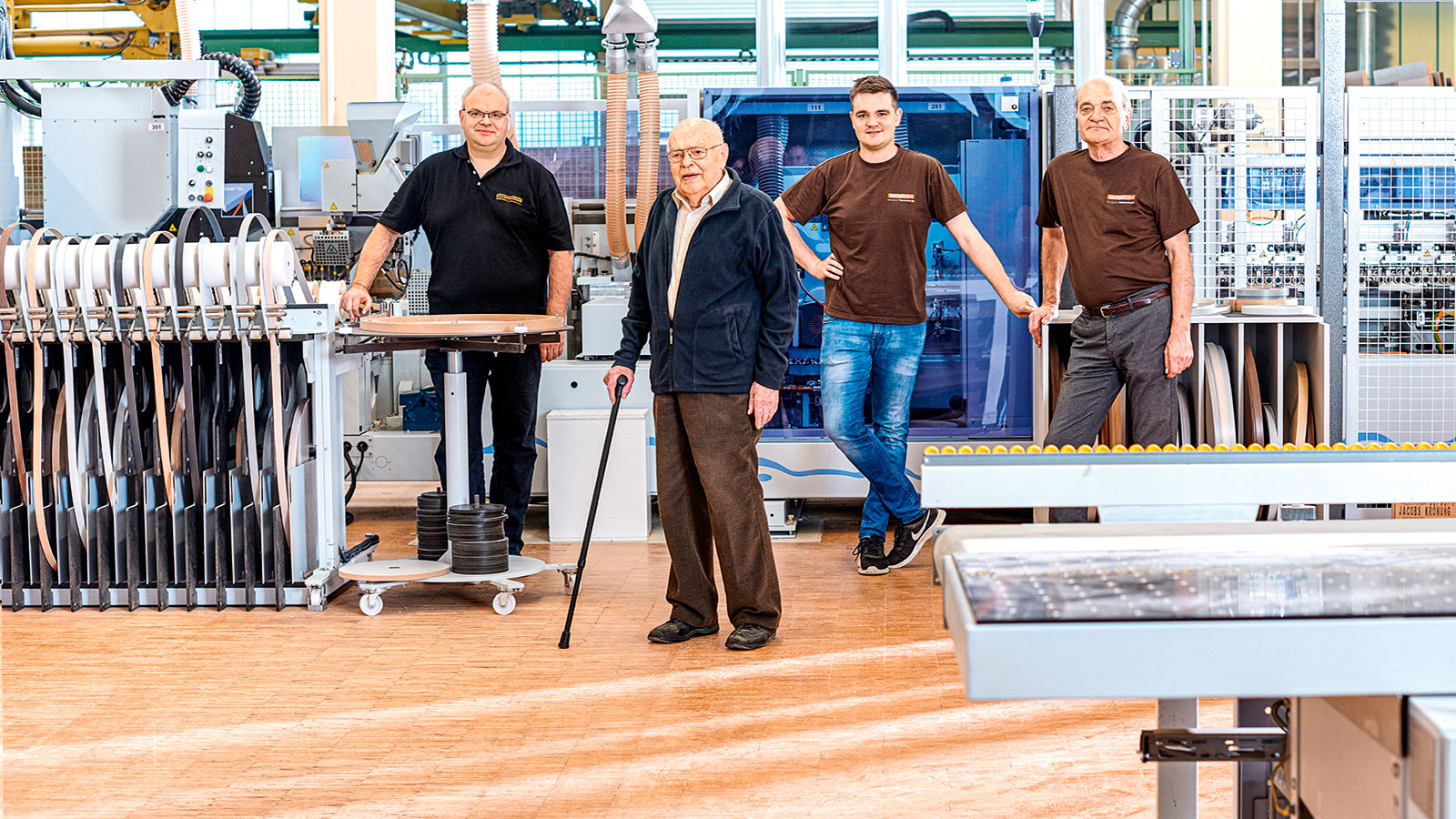

What‘s great is that the solution is right on the main street: the Amler joinery, founded in 1995 by master joiner Ludwig Amler. Since 2018, his son Christoph, who is also a master joiner, has been running the family business. Although the company started as a classic joinery for construction and furniture, the Amlers now focus more heavily on interior fittings and small series production. Over the years, they have made a name for themselves with architects and customers in this field, thanks to traditional craftsmanship and the latest technology.

The latest machines and flexible finance

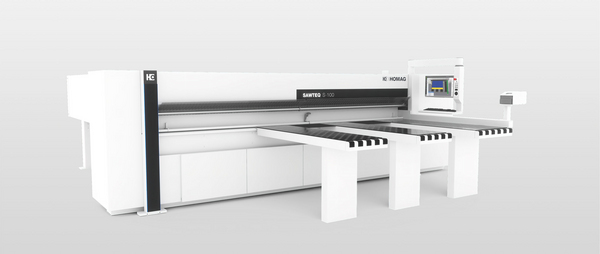

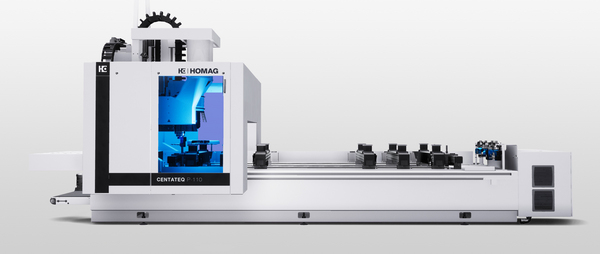

The starting point for the current machine pool was in 2018, with a HOMAG Edition 1440 (now: EDGETEQ S-300). The EDGETEQ S-240 would have been a real alternative, particularly with the new airTec hot air process. However, the Amlers intentionally chose the larger variant, as it was ultimately the edge that was often the bottleneck in production. However, that was not the end of the story; the order books were full to the brim. In 2019, therefore, along came the CNC — for one simple reason. As the level of orders remained consistently high, the joinery made further investments in both 2020 and 2021, first in a wide-belt sanding machine and then in a panel dividing saw.

For Christoph Amler, it was clear right from the start that the new machines had to come from HOMAG: „HOMAG stands for quality, the service and training are first class, the cooperation works and the proximity is of course a big advantage.“ The Competence Center in Denkendorf is less than half an hour away and Ludwig Amler has known HOMAG salesman Robert Herrler for ages. They both completed their carpentry training in the same company, almost 40 years ago. Today, Robert Herrler advises father and son on the machine selection and on financing matters.

The Amlers have a level-headed approach to investment, using leasing from HOMAG Finance. The fixed installments allow them to plan more reliably while tying up hardly any of the company‘s own capital. This means that the joinery will remain flexible in the future as well. The business manager has already made new plans for the joinery: in the medium term, there will be an extension with an exhibition space, but Christoph Amler doesn‘t want to rush anything.

A really good nursery

A large number of Amler customers also want to grow healthily: children. In recent years, the joinery has provided the interior fittings for several kindergartens. What‘s great for the little ones is that the joinery uses only good and certified raw materials, primarily from the surrounding region. This is where we find the showcase project of recent years: the Sulztaler Wichtelnest kindergarten in Mühlhausen. Curved shapes, bright colors and hidden passages all make the hearts of the children and carpenters beat faster.

It‘s no wonder that Christoph Amler occasionally had to rein in his two assistants and his intern Isabella. However, without this commitment and the machine support, the joinery would not have been able to fulfill the order. As other trades were delayed, the time frame for the interior fittings was continually shrinking. However, it was enough and the job was even completed quicker than planned, thanks to teamwork. The punctuality, the quality of the craftsmanship and the exact implementation of the customer‘s wishes impressed the developers and architects so much that the collaboration resulted in multiple subsequent projects. The children at the Wichtelnest kindergarten are also impressed. And, according to Christoph Amler, at the end of the day, that‘s what counts.

Maßarbeit – Issue 6 | 2021

“It‘s very hard to find good people at the moment. This makes the calculation easy: few people, lots of orders, equals CNC.”Ludwig Amler, Founder Bau- und Möbelschreinerei Amler

More about Amler joinery

Products: Interior fittings, small series production

Location: Fribertshofen, Germany

Founded: 1995

Employees: 7

First HOMAG machine: 1996

HOMAG machines used:

- Edition 1440 (today: EDGETEQ S-300) edge banding machine

- CENTATEQ P-110 CNC processing center

- SAWTEQ B-130 panel dividing saw

- W-100 wide-belt sanding machines