The new furniture parts center in the Martinov industrial park in Ostrava pushes the DÉMOS portfolio forward again = it enables customers to order an almost finished product – a kit of parts ready for assembly.

With a history of more than 20 years and 700 employees, DÉMOS are a significant supplier not only to customers in the Czech Republic, but also in Slovakia, Poland and Hungary. Apart from products from the portfolio of global manufacturers, DÉMOS also offer their customers consulting, a range of furniture fittings and a large variety of board materials - all in stock ready for shipping.

Production in Martinov is focused on working efficiently with large quantities of material. That is also why the 12-meter automatic storage STORETEQ S-200 is used for the basic distribution of material to the orders, which not only ensures the distribution of material for the panel saw, but also keeps track of the parts through the production process. The advantage of STORETEQ is that it is easy to connect to other machines in the production chain. In this case, it is a powerful panel saw SAWTEQ B-200 with the DustEx option for easier handling of boards and protection of boards from scratches. Due to the intuitive user interface and the ergonomic structure of the SAWTEQ B-200, the operator can easily cut a large amount of material. Of course, it includes the necessary label printer. The applied lables allow tracking of all parts in the production.

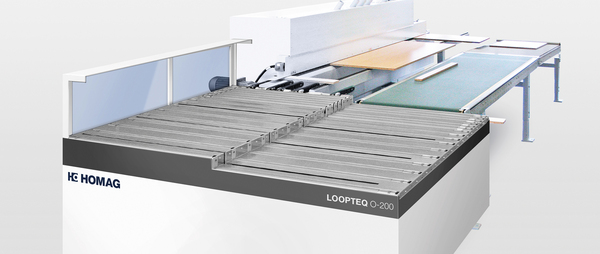

After cutting, the order is moved to the EDGETEQ S-300 edgebanding machine, where the LOOPTEQ O-200 return conveyor takes care of further logistics of the parts after edgebanding. The EDGETEQ S 300 edgebanding machine is a universal, powerful machine that is ready for all the tasks the manufacturer has. Together with the conveyor, it enables fast operation with significant savings in manpower. Part of the order then travels to the DRILLTEQ H-600, the fast horizontal drilling CNC which is particulary intended for industrial production. The CNC processing center is equipped with a prepositioning unit for loading parts and a bar code reader. Like its smaller siblings of the former BHX series, it is surpringly easy to operate. The equipment includes, of course, a grooving saw and a routing spindle. The main advantage is the possibility of machining two mirrored parts (eg. left + right side) in one step for a maximum increase in capacity. There is also the possibility of integrating a doweling unit into the machine.

DEMOS is constantly looking for ways to push the boundaries of its production forward, because they know the trends of the 21st century and the pace of today cannot be stopped. They are very pleased that HOMAG machines meet their demands and the partnership with the local dealer EPIMEX works very well.

DÉMOS

With a history of more than 20 years and 700 employees, DÉMOS are a significant supplier not only to customers in the Czech Republic, but also in Slovakia, Poland and Hungary. Apart from products from the portfolio of global manufacturers, DÉMOS also offer their customers consulting, a range of furniture fittings and a large variety of board materials - all in stock ready for shipping.

More about DÉMOS