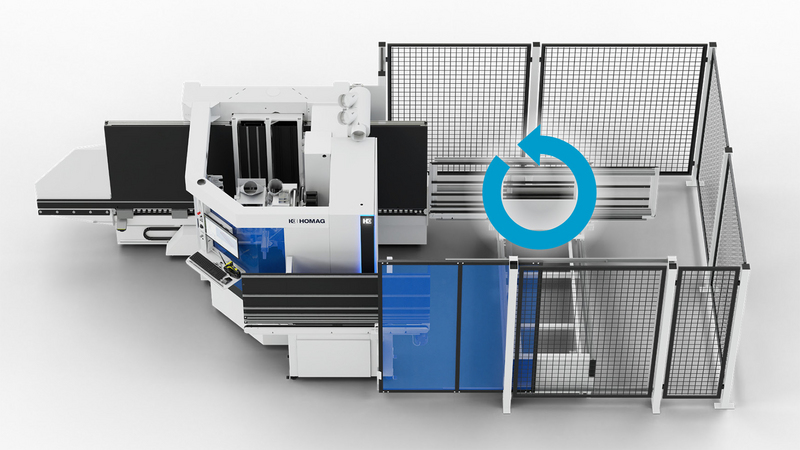

The motto from now on is "Turn it around!" New workpiece return system for the DRILLTEQ V-310

The new workpiece return system for the DRILLTEQ V-310 vertical CNC processing center has a special feature that its precursor could not offer: It reverses the parts. To process the 6th side, the workpieces are now automatically fed back into the machine without any additional manual intervention. It’s now a fully automated solution for complete part processing.

The workpiece return system is the perfect complement to the DRILLTEQ V-310 and optimizes the machining process by perfectly matching the characteristics of the CNC processing center. The material flow is automated and organized, and cost-effectiveness is increased. The result is a lean and efficient process that offers added value for every production solution, regardless of whether it’s batch size 1, order-based or series production.

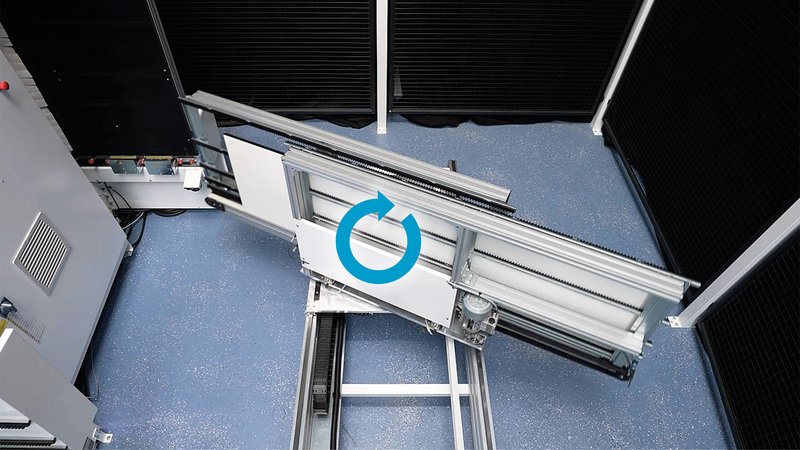

Reversing function offers complete processing

The 6-sided processing operation, which previously required the workpiece to be reinserted manually, now runs automatically in a single flow.

Manual intervention and reloading between the processing of the 5th and 6th side is not necessary. The result is better machine utilization and significantly reduced downtimes. Even large workpieces up to a length of 3,050 mm will be fully processed in an ergonomic manner in future. Manual part handling is reduced to a minimum, which also increases the quality of processing. Thanks to the turning function, one machine operator is sufficient to process the workpieces. The workpiece return is fully integrated into the machine's user interface and is operated via the powerTouch control system.

A "yes" to the automation of the DRILLTEQ V-310 is not a question of company size, but a prerequisite for greater economic efficiency. Workpiece return solutions are therefore worthwhile for anyone who operates a CNC processing center in their production.

Thanks to the new reversing function, "The Raumwunder" now also becomes a "amazing mover" by offering the workpiece reverse.