Based in East Kilbride, Laboratory Specialist Services Ltd. (LSS) is one of the UK’s leading manufacturers of specialist laboratory furniture, fume cupboards, and extract systems. For over five decades the company has served industrial, research, pharmaceutical, and educational clients, delivering tailored solutions and exceptional service either as a turnkey provider or as part of a wider project team.

As their client base has grown and projects have increased in complexity and size, so too have their manufacturing requirements. The company has continually invested in upgrading its workshop to keep pace.

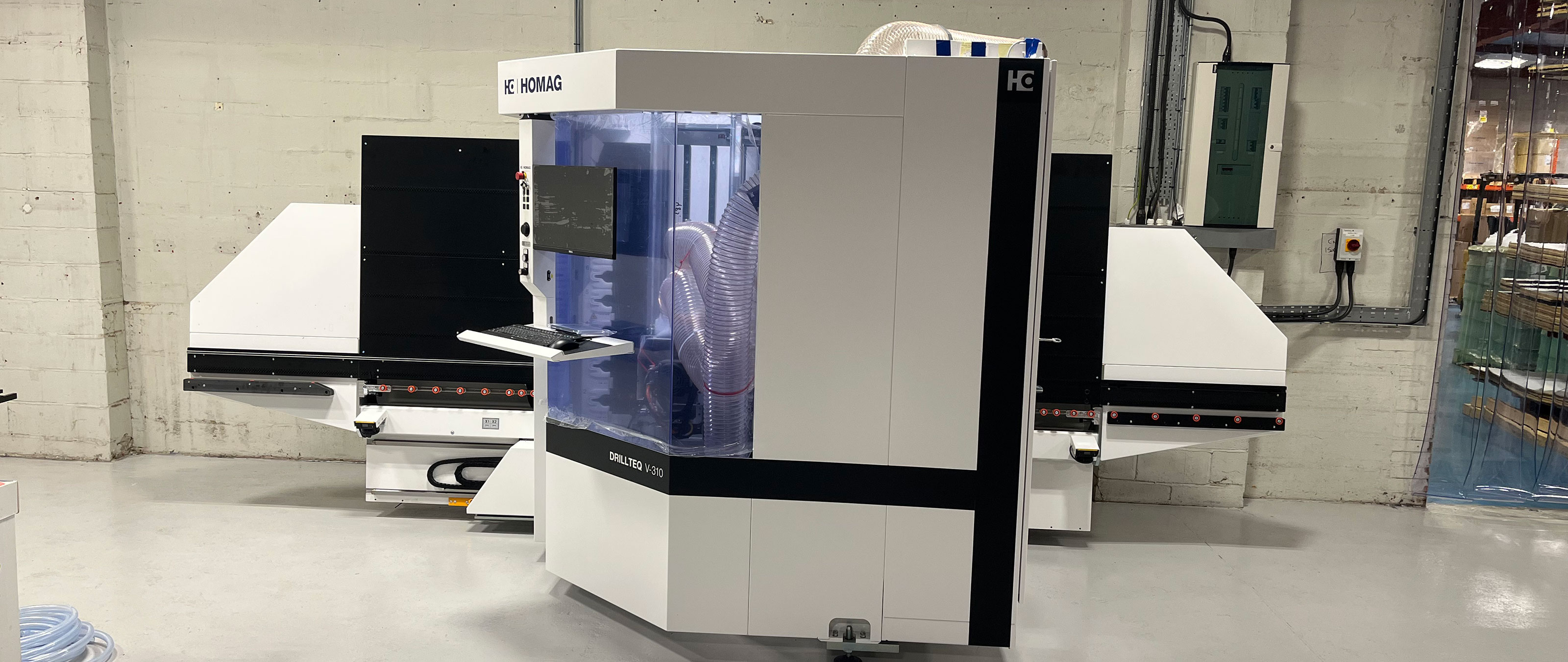

“When I started seven years ago, all we had was a panel saw and an edge bander,” explains Brian Daly, Production Manager at LSS. “Everything was done manually. Since then, we’ve added a beam saw and two CNCs, the most recent being the HOMAG DRILLTEQ V-310 – a transformational investment.”

Breaking the bottleneck

The company’s previous CNC had become a clear operational bottleneck. With a product range that spans lab furniture and worktops, the team was restricted to producing one or the other at any given time. “We wanted to run both in parallel to effectively double our capacity,” Brian explains. “But to do that, we needed a brand new beast of a machine.”

Having used HOMAG equipment throughout his career, Brian was confident in the quality and performance it could deliver. “When we were getting our beam saw a few years back, I gently insisted it be a HOMAG. They have always been exceptional. When it came to getting to the CNC, we went through the motions of exploring what else was out there. But in my experience, all roads lead to HOMAG, and this time was no exception.”

A thing of beauty

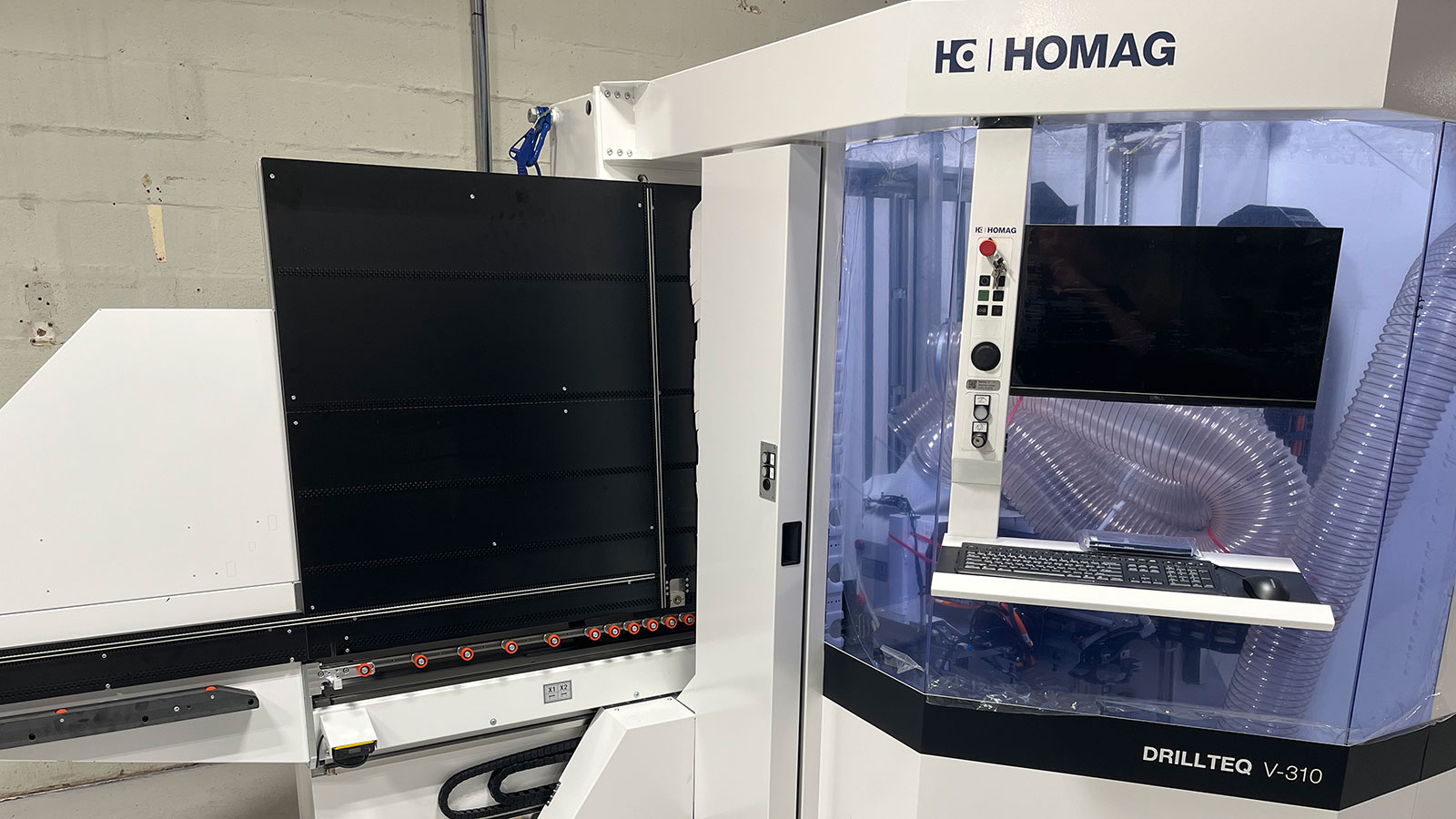

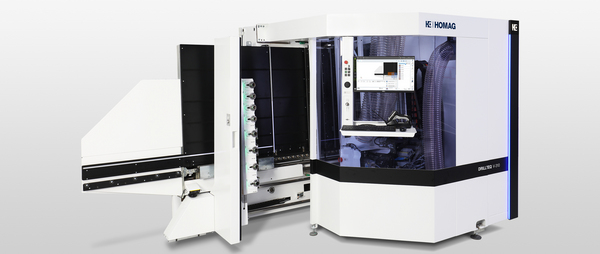

The team visited HOMAG UK’s showroom in Castle Donington for a demonstration of the DRILLTEQ V-310, including its software capabilities. “We had a great day out. The HOMAG team were very welcoming, lunch was included, and seeing the V-310 first-hand was a big moment. It’s a thing of beauty.

“One of the most appealing things for us was the size of it. We have limited floor space so we needed a CNC that could do a lot without taking up too much space. The DRILLTEQ V-310 is very compact, and yet it’s an absolute powerhouse.”

Another standout feature for Brian was HOMAG’s smartWOP software. “When I saw a demo of smartWOP it blew my mind. We’ll be getting it fully integrated later this year.”

Installation and training

The installation was carried out in collaboration with AWMS, HOMAG’s agent in Scotland. “We’ve worked with AWMS for years and I can’t speak highly enough of them,” says Brian. “This project was no different; all we had to do was sort out extraction and some wiring, and they handled the rest. It was probably the easiest installation I’ve had in my career.”

Training, delivered by AWMS’ Robert Herron, was equally efficient. “It was booked for four days, but Robert, a bonafide CNC wizard, was able to get us up to speed in just two. Since then he’s kept himself available to answer any questions, but for the most part we’ve been able to handle everything ourselves. He taught us well.”

Brian also credits AWMS’s Kenny Dickson, Andrew Carson, and John Small for the seamless process, from pre- to post-sale. “It’s no wonder HOMAG trusts them with their Scottish accounts. They do a fantastic job.”

Rapid results

With the V-310 now fully operational, LSS is already seeing the benefits. “We no longer have to alternate between manufacturing lab furniture and worktops, and the implications of this for our business are huge. We are well on track to double our capacity.

“What’s more, the capabilities of the machine are such that we can confidently take on bigger projects. Before, £500,000 was a big contract for us. Now, we’re quoting for £2 million jobs. That’s the kind of level we’re looking at now, and with this in mind, we expect the machine to pay for itself within the first year, easily.”

Brian concludes, “You always know what you’re getting with HOMAG: quality beyond compare and the service to back it up. As if I needed reminding, this latest investment has demonstrated the ways in which their machines can transform a business. I don’t think I’ll have any trouble persuading my colleagues at LSS to stick with HOMAG for future investments!”

For more information or a demonstration of HOMAG’s machinery and software, please contact HOMAG UK on 01332 856500, option 4 for the sales department. Or email info-uk@homag.com.

“You always know what you’re getting with HOMAG: quality beyond compare and the service to back it up.”Brian Daly, Production Manager at LSS

Laboratory Specialist Services Ltd

Located in Newton Aycliffe and part of the McQuilkin Group – A family business for over 100 years

labspecialistservices.co.uk