KWB London specialises in bespoke kitchens, bedrooms, bathrooms and concierge fit outs for the London contract residential market. Founded in 2012 by joiner Kevin Behan, KWB’s focus on quality and service has given rise to rapid expansion. Since 2015, the company has been working exclusively with the large tier 1 contractors in London.

“We’ve been lucky to be invited to do some prestigious work, perhaps the most notable being Chelsea Waterfront which is our latest project,” explains KWB’s owner, Kevin Behan. He continues, “The gap in the market we fill is producing very bespoke joinery detailing in volume, something the larger outfits struggle to achieve.

“As our business began to take off, we realised we had to invest in better, larger CNC machinery. So, in 2016, we visited the Ligna show to research the market. That was a real eye-opener for us, and we were particularly impressed with the breadth and depth of the HOMAG presentation.”

Swayed by price

“Despite feeling that HOMAG’s solutions were technically superior, we made the mistake of being lured by a lower-priced alternative. Unfortunately, we very quickly learnt the error of our ways. The cheaper machine ended up costing us dearly, as we suffered all sorts of issues and downtime which held back our progress.

“It was during the first lockdown period in 2020 that it became clear the time was right to make the next major investment in the business. Throughout the COVID crisis we kept operating, but many of our suppliers didn’t, and this exposed weaknesses in our supply chain.

“Hindsight is a wonderful thing, but we weren’t about to make the same mistake again. So when it came to investing in new machinery and software to take us to the next level, we turned to the major players. Yet again, HOMAG came out on top and so we decided to partner with them.”

Specifying the right equipment

“Before approaching HOMAG we analysed our production processes. We highlighted the machinery we felt we needed to create a workshop that would not only produce the right volume and quality for our customers, but also enable us to grow the business.

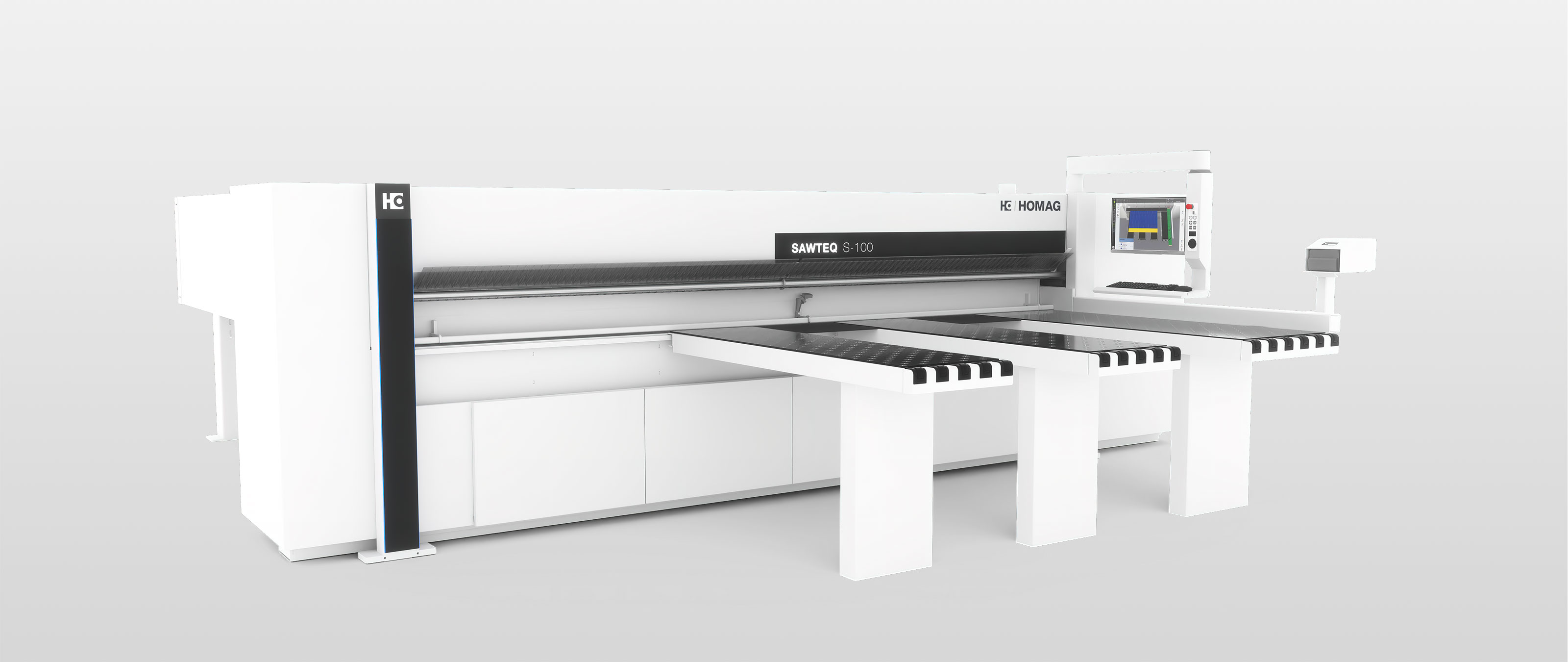

“Our plant wish-list included a beam saw with an automated panel lifter, an edge bander, a vertical CNC drill and a carcass press. Working closely with the HOMAG team we finalised our order for a SAWTEQ B-130 with panel lifter, an EDGETEQ S-300, a DRILLTEQ V-200 and a CABTEQ S-250.

“It’s very disruptive, changing your whole 10,500 sq. ft. workshop with new equipment, but HOMAG’s installation organisation and planning was excellent. From the moment we placed the order for the kit, they kept us informed of the delivery time frame. True to their word, their engineers installed all the machinery at the end of September, and I must say, they did an amazing job.

“The engineers weren’t precious, they just cracked on with installing the new machines. This enabled us to get on with our day-to-day production with minimal disruption; it really was a seamless process.

“Within a week all the machines were commissioned, and the engineers then trained our guys on site. This was supported by online training via Teams prior to the installation. HOMAG will also be providing refresher courses and advanced training online as and when we need it.”

Service and spares

“Aside from the quality and performance of the HOMAG machinery and easy to use woodWOP software, another deciding factor in partnering with them was the level of service and support they offer.

“HOMAG has its own team of engineers in the UK and consequently is able to provide an exceptional level of service. Not only that, but our research showed they also hold a comprehensive stock of spare parts. So, in the unusual event of a machine issue, they will be able to get us back up and running very quickly, and that is vitally important to us.

“Obviously, with five machines and software, this was a significant investment for a £5.5 million business like ours, but again, HOMAG was able to help. They introduced us to HOMAG Finance, who made it very easy for us putting together an attractive investment package.”

The results speak for themselves

“The new equipment has revolutionised our production; we are seeing efficiency gains 30 per cent higher than before, particularly with the automated SAWTEQ B-130 beam saw and the EDGETEQ S-300 edge bander. For example, on the new edge bander we can change between tape thicknesses, widths and diameter of radii without having to stop the machine; it’s all done at the touch of a button.

“There are hidden benefits too; when we invite potential customers to our facility the image the HOMAG equipment creates is hugely beneficial. It gives clients confidence that we can achieve the results they want and so it is definitely helping us to clinch contracts.

“Our employees too have gained in stature; they see they are in a truly professional environment and consequently have gained a deeper sense of pride in their work,” concludes Kevin Behan.

“Aside from the quality and performance of the HOMAG machinery and easy to use woodWOP software, another deciding factor in partnering with them was the level of service and support they offer.”Kevin Behan, Owner, KWB London