As part of a strategic expansion into fire door manufacturing, Glasgow-based construction and fit-out specialist Hugh Stirling has invested in a HOMAG CENTATEQ P-110 CNC and an EDGETEQ S-200 edge bander. The move is aimed at supporting the company’s growing fire door division while maintaining quality across its broader joinery operations.

For over 60 years, Hugh Stirling has built its reputation on personal pride, high standards, and a collaborative approach, delivering bespoke interiors and construction projects across commercial, hospitality, and industrial sectors. The company currently employs around 130 skilled tradespeople and staff, combining traditional craftsmanship with advanced manufacturing technology.

A growing focus on fire doors

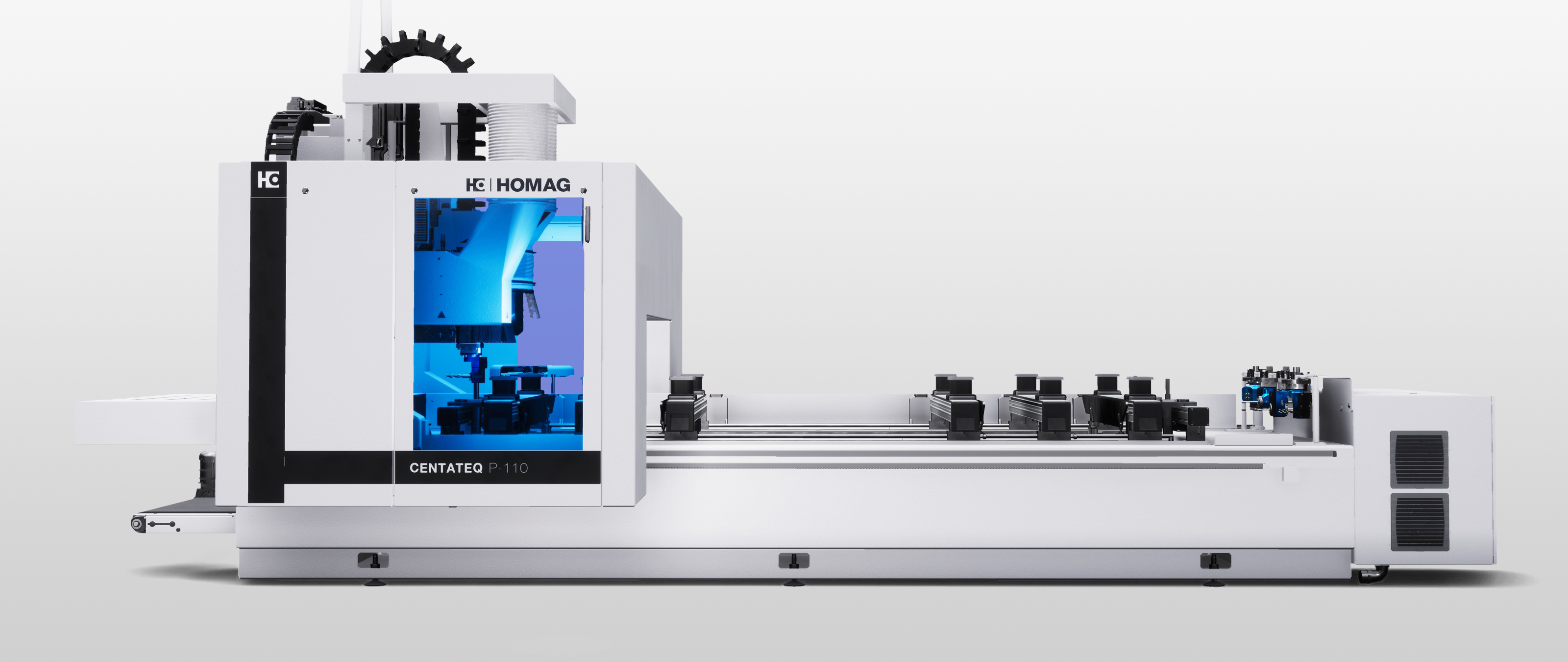

The investment in new HOMAG machinery comes as Hugh Stirling scales up its fire door offering. “We’re a multi-faceted business,” explains Brian Muslek, Managing Director at Hugh Stirling. “We do everything from bespoke joinery and facilities management to full interior fit-outs – anything from pubs to power stations. Our fire door division has been growing, and our existing CNC was reaching capacity with bespoke joinery work. The HOMAG CENTATEQ P-110 is a dedicated solution for fire door production.”

The new EDGETEQ S-200 is enhancing joinery operations, while the previous edge bander has been redeployed to the fire door line. Together, the machines help balance production and support higher throughput.

HOMAG quality and local support

For this investment, Hugh Stirling was keen to find a solution that delivered reliability, precision and strong local support.

“Our other machines are from different manufacturers, all of which continue to serve us well,” says Brian. “One thing that drew us initially to HOMAG for this investment was their locality. They have a local sales and service partner in Scotland, AWMS, who have been fantastic throughout the process. Kenny from AWMS has been a great point of contact, guiding us through the process and providing technical information during the purchase and installation.”

“Aside from local support, build quality was a major factor in the decision. Our experience with other high-quality machinery meant we knew what to look for. It was clear that HOMAG’s kit would suit our needs.”

Smooth installation and early results

Despite some infrastructure adjustments on Hugh Stirling’s end, the installation proceeded smoothly. “HOMAG and AWMS were incredibly flexible,” says Brian. “They managed the installation around us without any issue.”

Once operational, the CENTATEQ P-110 quickly began delivering results. “It’s a really impressive piece of kit,” Brian continues. “Our production team reports that features like the LED setup guides and tandem table machining are helping reduce setup times and improve throughput. We’ve seen an increase in output per hour, and we expect further gains as our team fully familiarises itself with the new workflow.”

User-friendly precision

Ease of use has also been a major advantage. “The woodWOP 9 software and PC 87 operating system are fantastic,” says Brian. “According to our operators, they are intuitive, app-based, and very quick to learn. Some CNCs require a lot of training and experience to operate. With woodWOP, any operator can program a job in under a minute. It’s as simple as clicking what you want the machine to do with no fuss whatsoever.

“We also added an aggregate tool, which has halved the time it takes to run and pilot hinge holes, all in a single pass. It’s boosted both speed and accuracy, and gives us the flexibility to carry more tooling options.”

Partnership and support

The experience of working with HOMAG and AWMS has been extremely positive. “It’s early days, but so far, anything we’ve needed has been done promptly and professionally. Between HOMAG’s quality and AWMS’s local support, we have a lot of confidence moving forward.”

Looking ahead

With the new HOMAG machinery now fully operational, Hugh Stirling is well positioned to expand its fire door production and strengthen its bespoke joinery operations. “It’s an exciting time for us,” concludes Brian. “The new machines support our growth and help maintain the quality our clients expect. We’re looking forward to seeing the full impact on production over the coming months.”

For more information or a demonstration of HOMAG’s machinery and software, please contact HOMAG UK on 01332 856500, option 4 for the sales department. Or email info-uk@homag.com.

“It’s early days, but so far, anything we’ve needed has been done promptly and professionally. Between HOMAG’s quality and AWMS’s local support, we have a lot of confidence moving forward.”Brian Muslek, Managing Director at Hugh Stirling

Hugh Stirling

For over 60 years, Hugh Stirling has built its reputation on personal pride, high standards, and a collaborative approach, delivering bespoke interiors and construction projects across commercial, hospitality, and industrial sectors.

hughstirling.co.uk