Successful software implementation by SCHULER Consulting at joinery in Lleida (Spain)

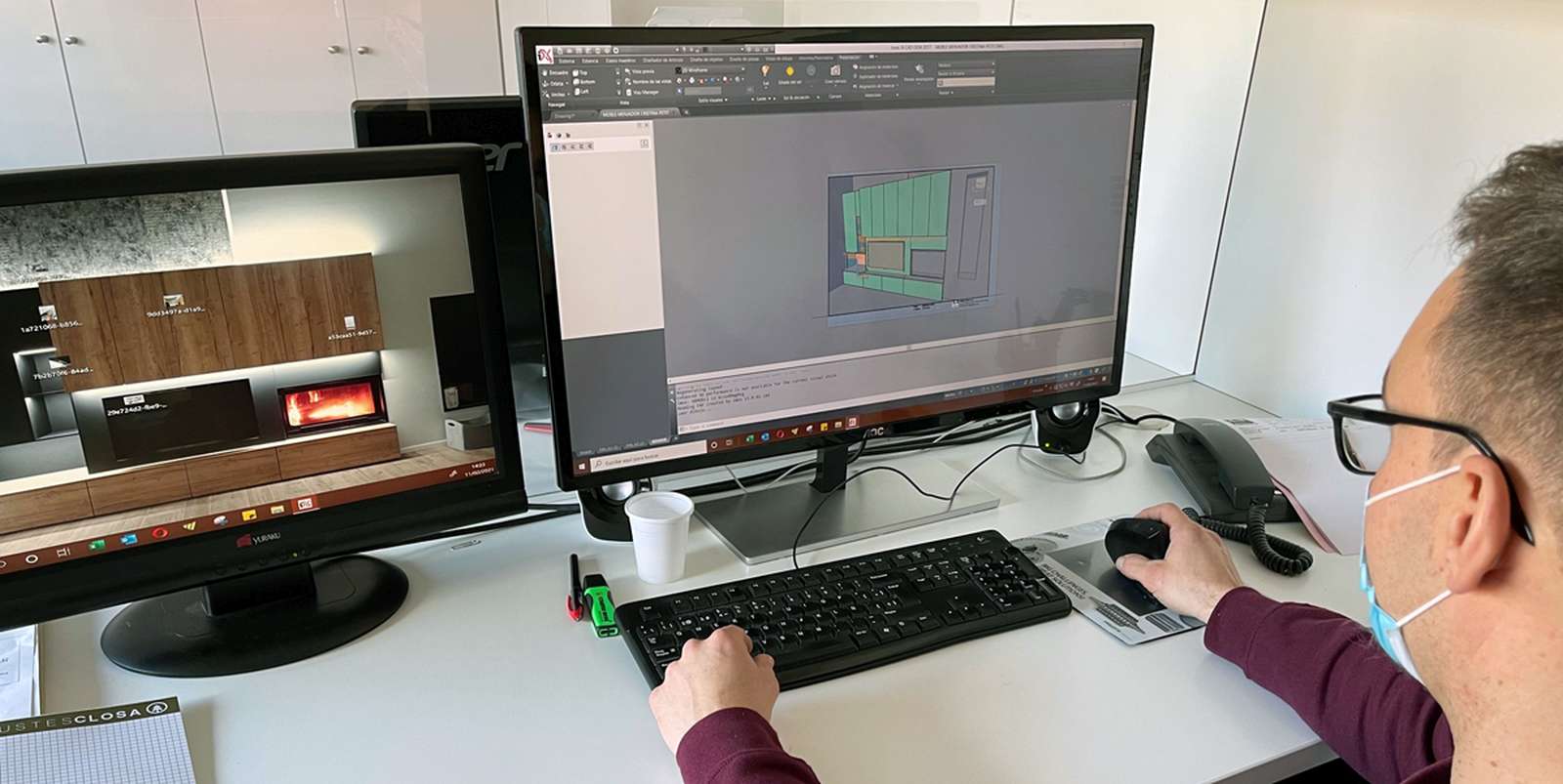

The carpentry BERBIO FUSTERS - B&B continues to make progress towards complete automation. After the installation of a second CNC machining centre, the technical office now controls the production of furniture with the CAD-CAM programme of the renowned German company imos.

Two years ago, when the orders became more and more complex, BERBIO FUSTERS decided in favour of imos. The basic software of the two CNC machining centres was no longer sufficient to handle the increasingly demanding projects. "With imos CAD-CAM, B&B can meet all the requirements they have," says Maria Garcia, Product Manager at SCHULER Consulting. SCHULER Consulting has been a distributor for imos software in Spain for more than twenty years.

CAD-CAM is the core and basis of the imos solution. It enables the carpenter to design and manufacture furniture automatically. On the one hand, imos covers the work step of room planning and its presentation to the customer with technical layout plans. On the other hand, the software offers the possibility to automatically export the design of the rooms and their furnishing to the cutting as well as to the machining centres. In the near future, B&B Fusters will consider integrating modules for sales and quotation.

AUTOMATION AND DIGITALISATION

BERBIO FUSTERS has made great strides not only in automating its manufacturing process, but also in terms of digitalisation. For example, part of the implementation of imos carried out by SCHULER Consulting was to optimise the label that contains the information required for the production of each piece of furniture. Now, each label carries information about the part, its cutting and machining process, as well as the order number and customer name. It contains all the necessary information to identify each piece in production and manage it correctly up to the last step, the logistics. The implementation of imos thus significantly improves and structures the work of BERBIO FUSTERS.

"We gain precision in optimising materials and agility in the manufacturing process without making mistakes on the shop floor. Because the instructions come revised and contrasted from our own technical office, where we have two people who draw and organise production," explains Toni Bernaus, Managing Director of B&B Fusters. "It was a 180º turnaround. It has nothing to do with the way we worked before."

The path of an order from entry to production is now structured and precise: a project is received by BERBIO and prepared in the technical office. From there, the precise instructions are sent to the machines. Everything is carried out down to the last detail, without restrictions and with absolute precision. This goes so far that imos warns of possible errors in the design and proposes solutions to correct them.

"Imos is compatible with the CNC machines we operate," explains Toni Bernaus. "The combination of imos and the numerically controlled machines gives us greater ease in carrying out any project and the certainty that we will not make any mistakes."

TRAINING AND CONSULTING

BERBIO FUSTERS has been very satisfied with the prior consultation, training and technical support provided by SCHULER Consulting after the software purchase. "We always accompany the client during the implementation of the software so that the development of the project is successful," explains María García. "We train them on how the programme works and advise them on how to create their own catalogue. During the training, we carry out practical applications with real customer models with the staff."

At the end of the imos implementation phase, B&B Fusters already had a database of its products. From there, they could continue to develop it themselves. SCHULER Consulting maintains direct contact with the customer through a dedicated technical support team and answers all questions that arise during the catalogue creation process.

After twenty years of sales partnership with imos in Spain, SCHULER Consulting's collaboration with the German brand's highly qualified team of engineers, specially trained for the furniture industry, is very close. "We have a broad technical background in all aspects of production, fittings, components and end products for the implementation of imos in small, medium and large companies," says María García.

B&B Fusters does not produce furniture in series. Everything is made to measure, each project is personalised. Kitchens, bathroom furniture, dining rooms, doors - from complete room redesigns to individual pieces of furniture. "With imos, we are a modern, competent and competitive joinery," sums up Toni Bernaus. "With imos, there are no limits. You make and learn, and you see that you can do many things with it. You work in detail, which is ultimately our way of working."

IMOS OPENS UP NEW DIGITAL PATHS FOR THE WOODWORKING INDUSTRY

The imos iX 2019 software release is the result of the technological development that started in 2017. The trends and technologies of digitalisation have been incorporated into the development and offer new possibilities, from the end customer to the machine. imos AG has deepened the focus on virtual reality and further realised the concept of an end-to-end complete solution.

The result is a holistic and optimised process that is fully adapted to the usage profiles of the furniture industry. This makes iX 2019 even more integrative and consistent than its predecessor.

In addition to the revised user interface, special emphasis was placed on user-friendliness, making the new version significantly easier to use. The core modules of iX such as CAD, CAM, NET, PLAN and iFurn have been revised and convince with new functions for the user in industry and tra

BERBIO FUSTERS

The furniture manufacturer Berbio Fusters relies on imos CAD|CAM to process increasingly complex orders. SCHULER Consulting supported the company in the software selection and implementation.

"With imos we are a modern, competent and competitive joinery. With imos there are no limits" - Toni Bernaus, Managing Director B&B Fusters.

>> More about B&B Fusters