Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

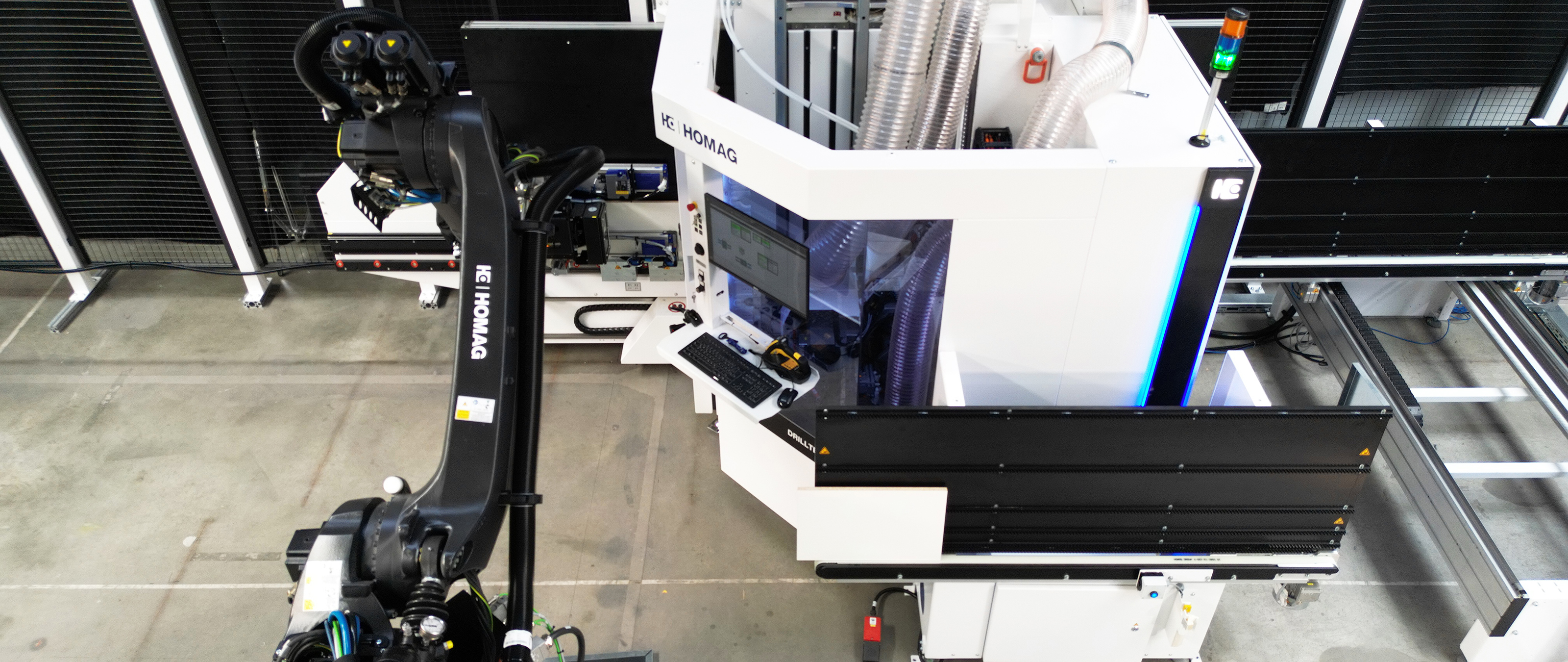

Robot Solutions for the Furniture Industry FEEDBOT D-310

Robot Solutions for the Furniture Industry FEEDBOT D-310

Safe, precise, automatic handling of workpieces for more efficient production

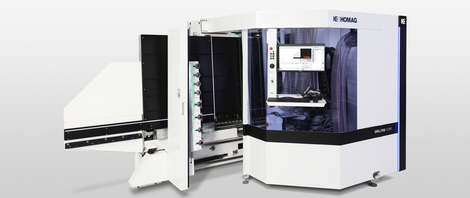

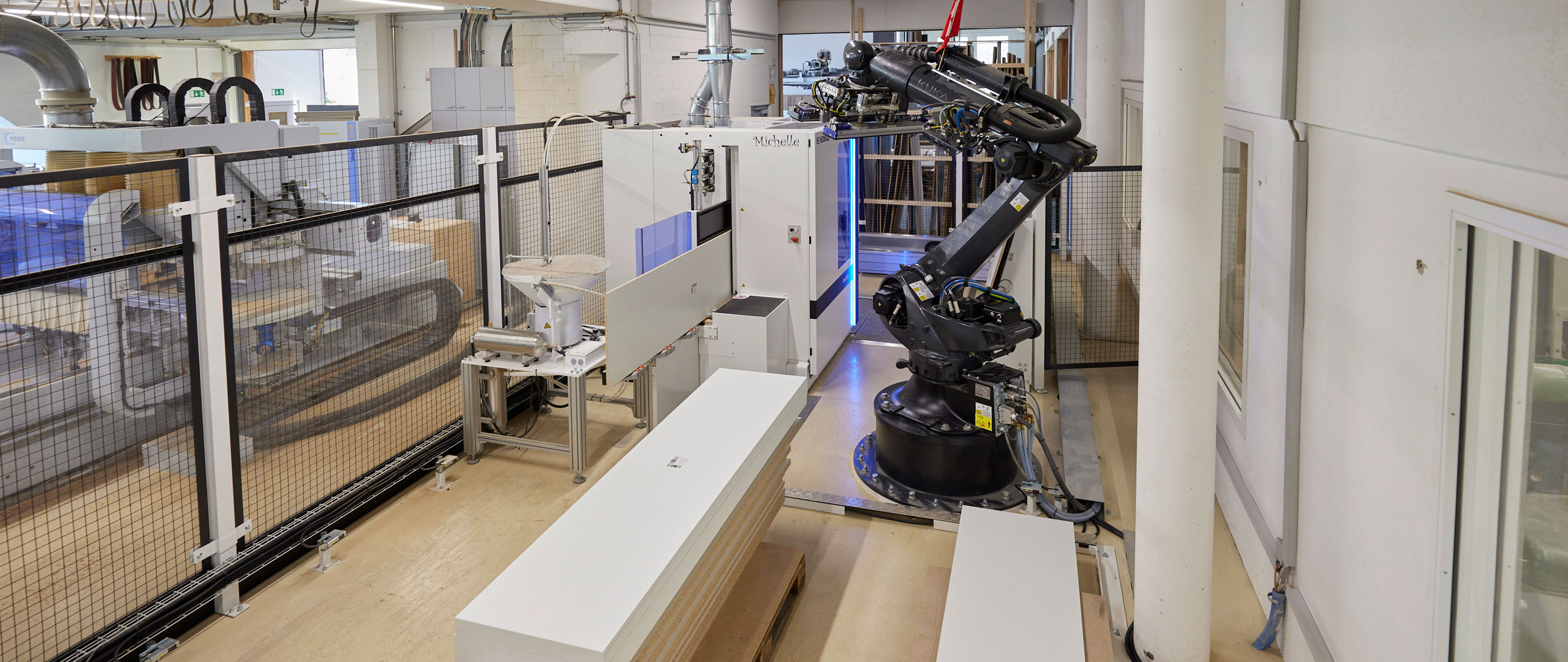

The CNC processing center with robot support forms one of the smallest possible cells of the furniture production. In this combination, the FEEDBOT D-310 increases your overall productivity. It does not have to take a break, can work around the clock on the shop floor and ensures consistently high quality. Small and medium-sized companies save a lot of time by using the robot integration FEEDBOT D-310 and reduce the workload for their staff. The resulting flexible manpower organization allows your workforce to be used more for value-added activities and production processes. The result is added value for your plant in terms of quality, availability and performance.

Images

Features

-

Everything from a single source from HOMAG (Liability and safety, CE, one contact, HOMAG service)

-

Processing on both sides possible due to return conveyor reversing function at the drilling machine

-

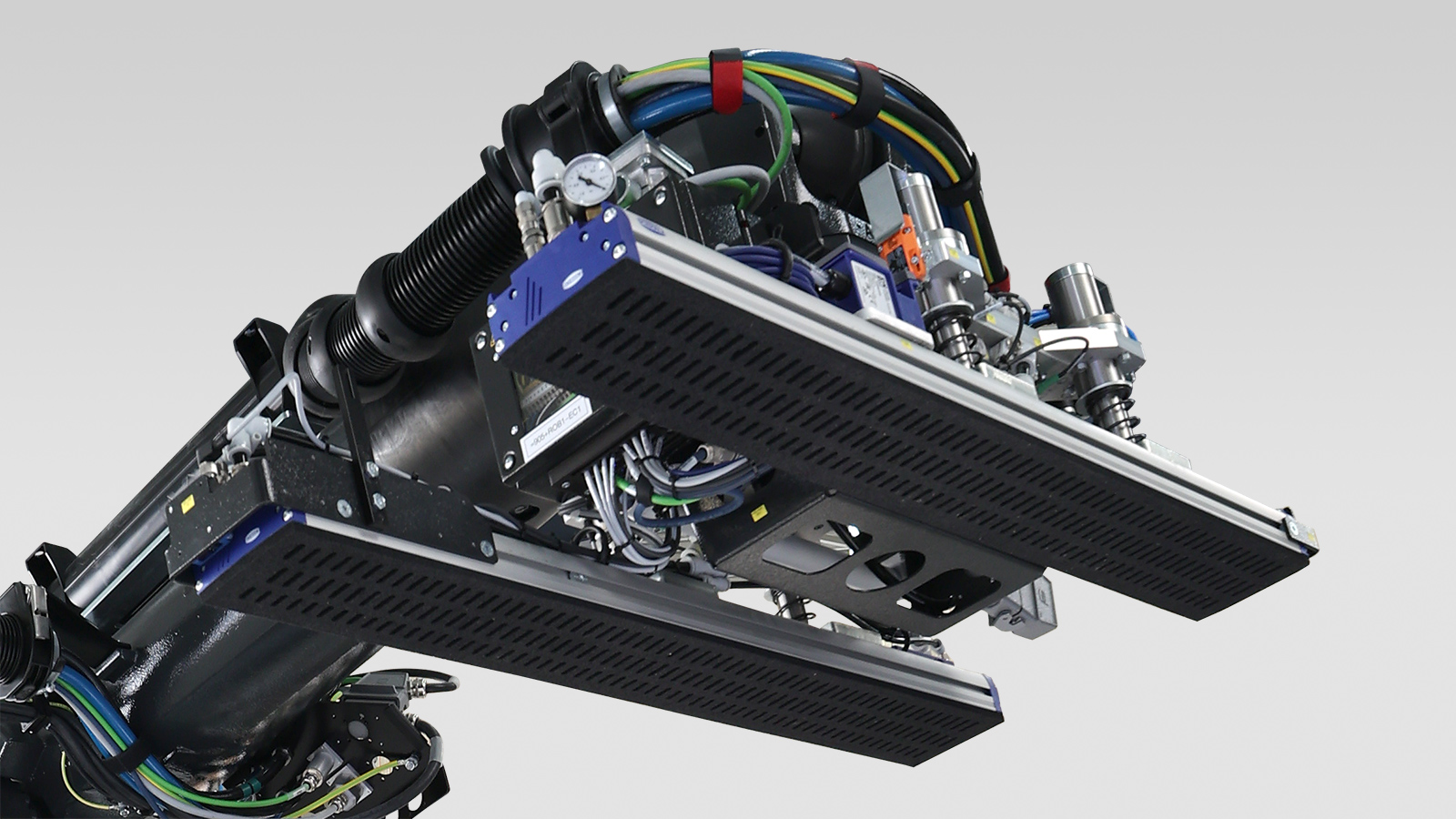

Robust suction technology and high-quality crosshead lead to high process reliability

-

Sensitive contact with the CNC pins - thanks to the floating crosshead - ensures gentle operation

-

Large workpiece variance

-

Automatic setup of the cell (CNC and and robot) as well as visualization in woodFlex

-

Plausibility check - comparison of the data from the control to the actual part

-

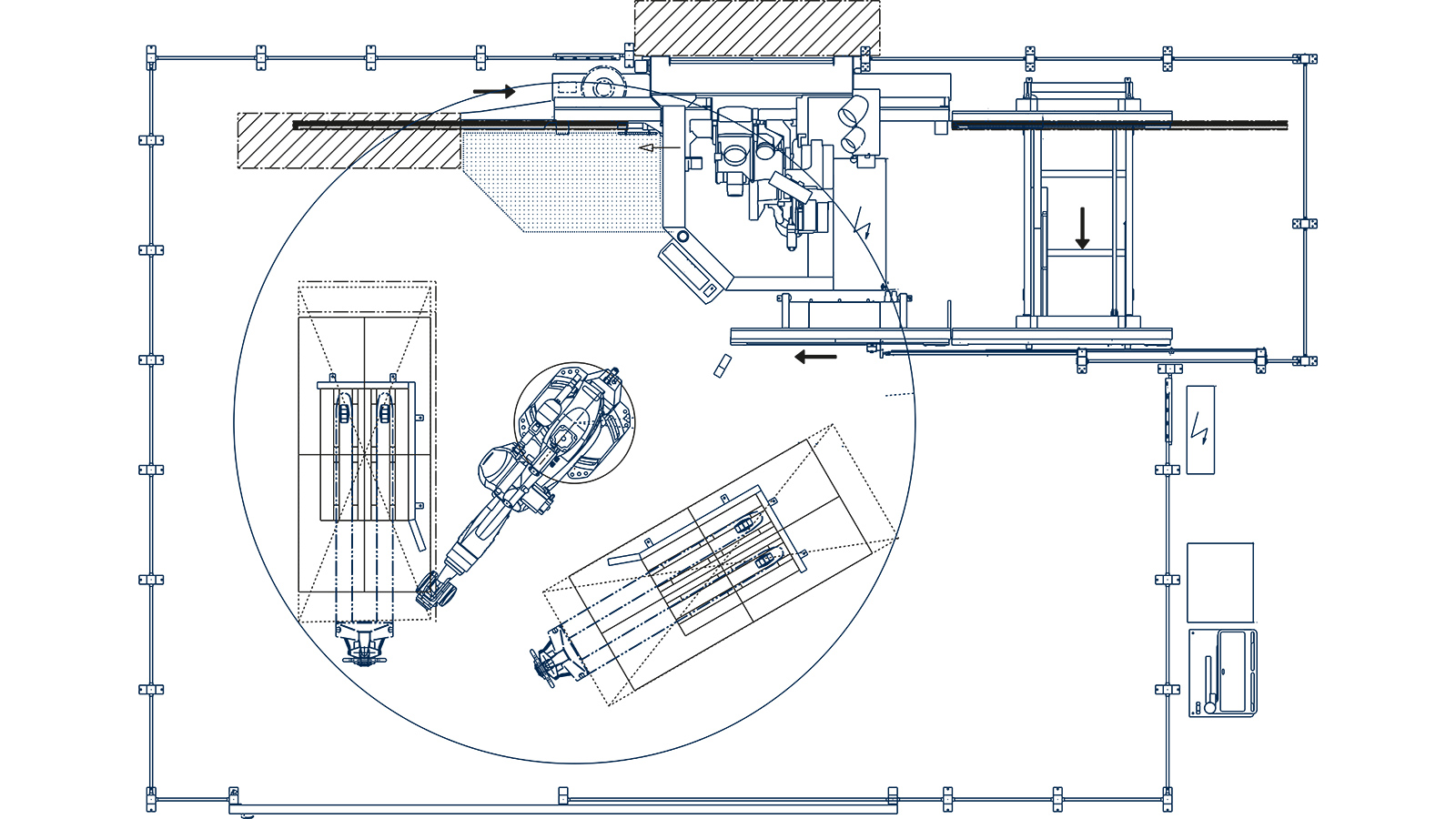

Space-saving, fully automatic loading and unloading by robot

-

Additional standard layer patterns (up to 4 different series stacks on one pallet)

-

Extended layer patterns for batch size 1 (2 fir tree stacks on one pallet) possible

-

Cell control and integration of the robot in the HMI of the DRILLTEQ V-310

Technical Data

| Technical Parameters | |

|---|---|

| Carrier material | Chipboard, MDF, HDF, plywood, solid wood |

| Surfaces | Melamine, Raw (carrier material does not soak through), Veneer, Laminate, No overlap (optional) |

| Special workpieces | Highly structured or absorbent materials and workpieces with high adhesion must be requested separately. |

| Stacking hight max. incl. base frame [mm] | 1,500 |

| Technical Data | DRILLTEQ V-310 with FEEDBOT D-310 |

|---|---|

| Workpiece dimensions max. with manual feeding [mm] | 3,050 x 1,250 x 80 |

| Workpiece dimensions min. with manual feeding [mm] | 200 x 45 x 8 |

| Workpiece dimensions max. with feeding via FEEDBOT D-310 [mm] | 2,500 (3,050 Opt.) x 1,200 x 60 |

| Workpiece dimensions min. with feeding via FEEDBOT D-310 [mm] | 350 x 120 x 10 |

| Workpiece weight max. [kg] | 60 |

| Installation dimensions [mm] | 11,500 x 7,000 x 2,160 |

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

HOMAG DRILLTEQ V-310 | Automatic material handling with FEEDBOT D-310

A CNC processing center with robot support forms one of the smallest possible cells of the furniture production.

Brochures