Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Edge Banding Machines EDGETEQ S-810

Edge Banding Machines EDGETEQ S-810

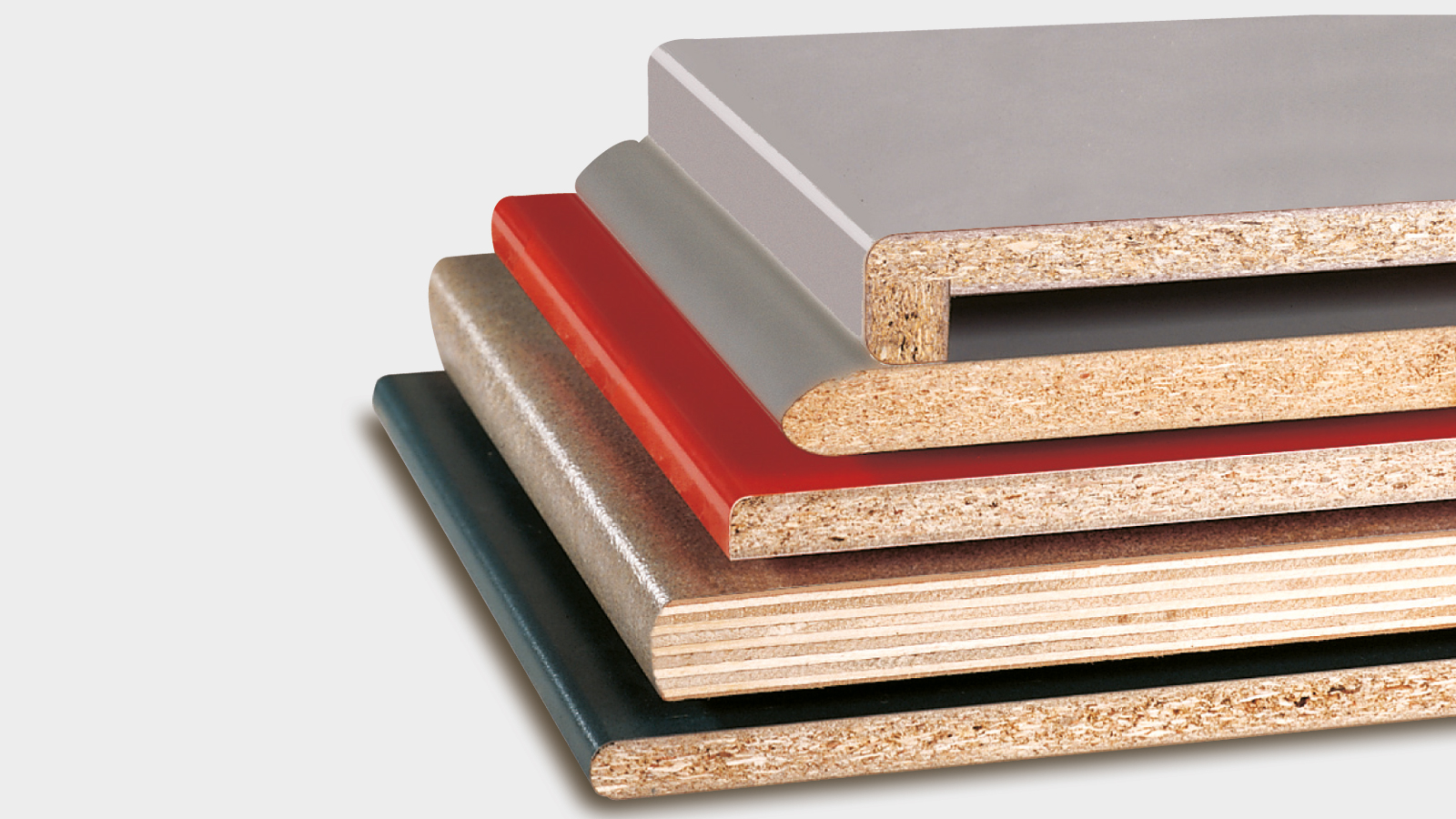

Pre-coated panel in – postforming part out

A postforming process provides the surface and edge of a workpiece with a continuous laminate coating for optimum protection. This technology is ideal for any application involving mechanical, thermal and chemical stress or moisture. Only one machine is needed, as the panels processed to produce postforming elements are already fully coated.

Images

Features

-

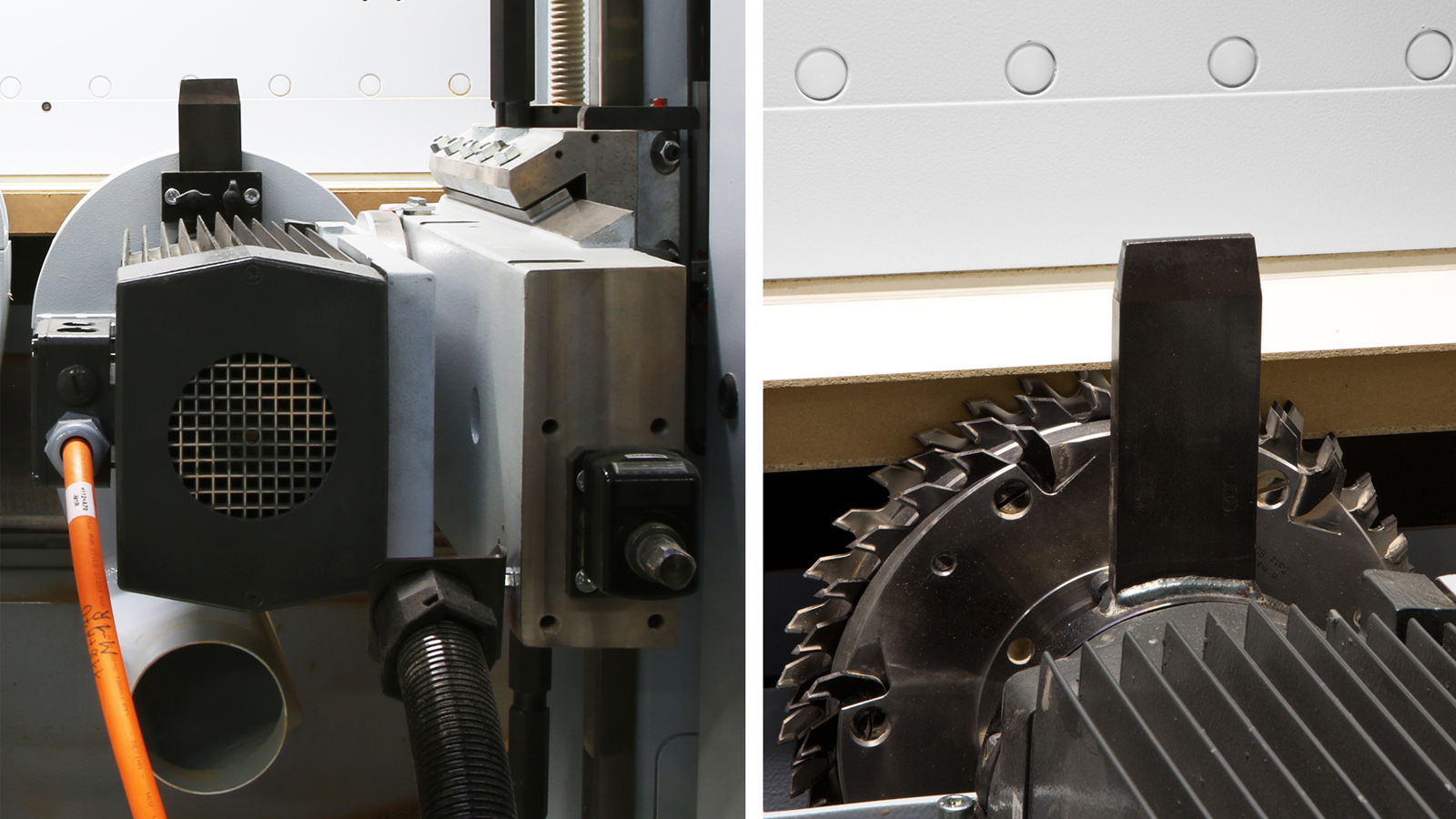

Postforming sizing unit for trimming excess laminate

-

Postforming units for scoring and smoothing when processing surfaces of U-profiles

-

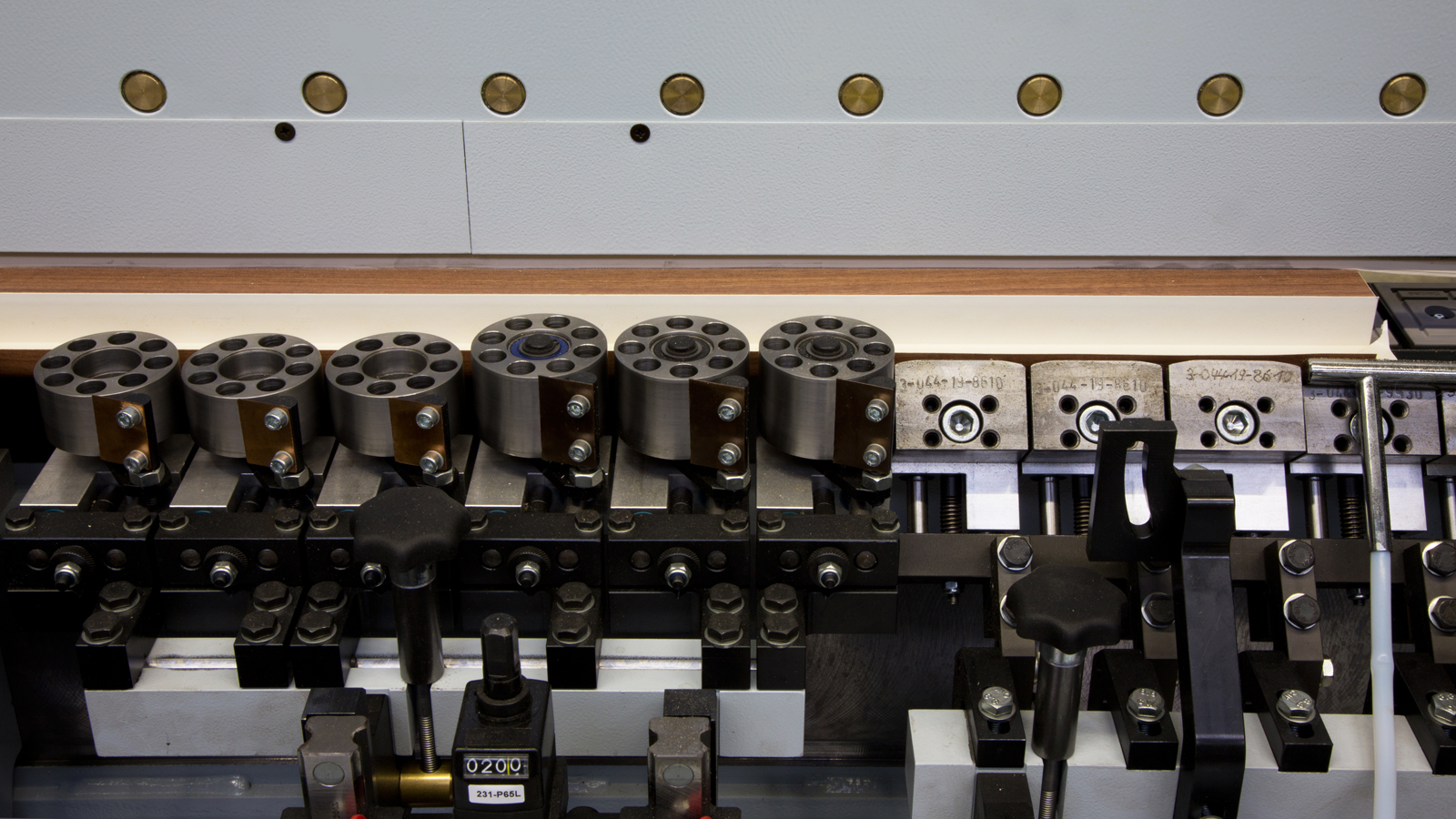

Glue application with nozzles

-

Side glue application with roller

-

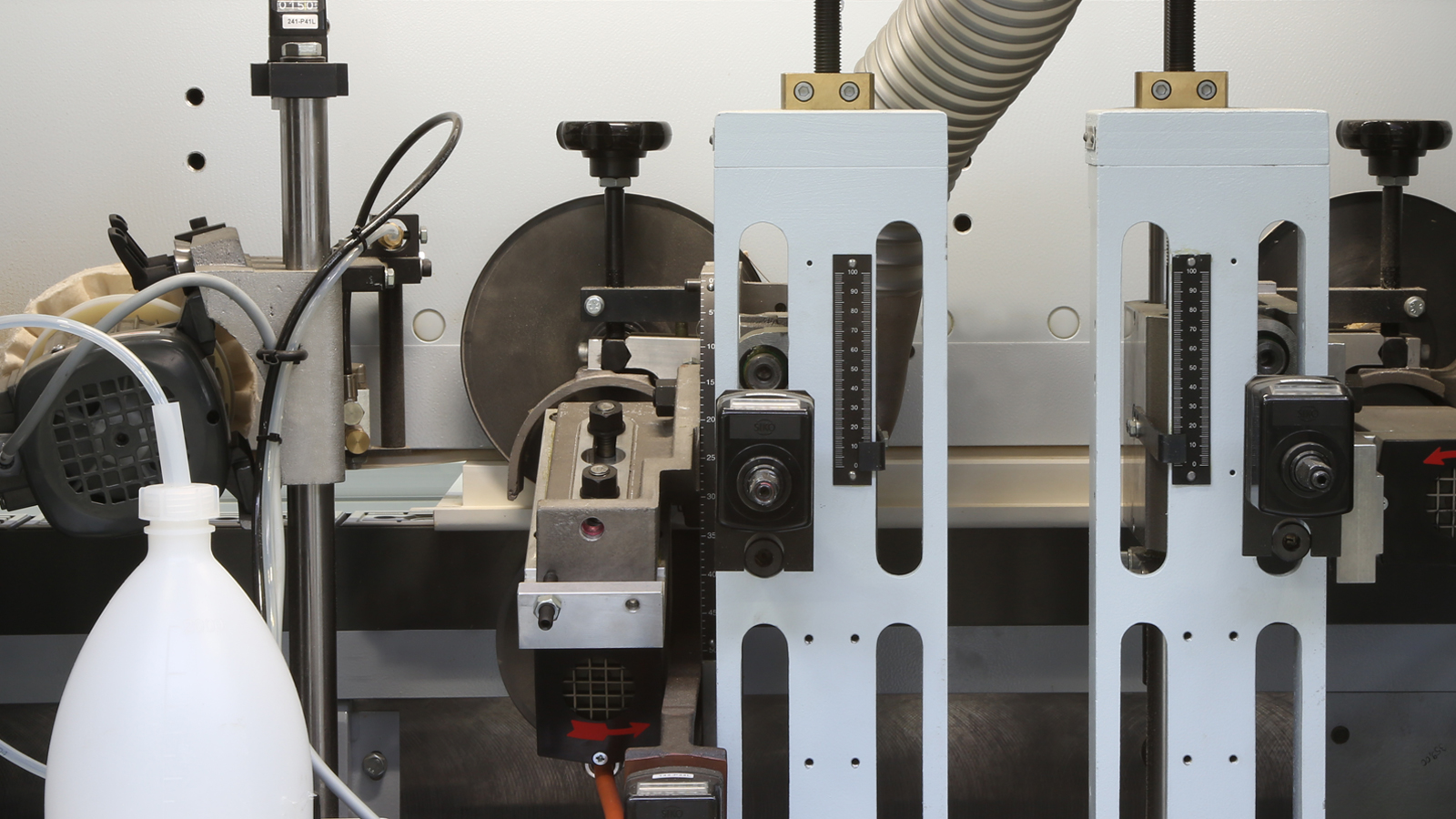

Individually adjustable heaters for the thermal preparation of the laminate for shaping

-

Pressure zone for shaping the laminate and pressing into the shape of the carrier material

Technical Data

| EDGETEQ S-810 Postforming | |

|---|---|

| Workpiece width [mm] | min. 150 |

| Workpiece thickness [mm] | 16–60 |

| Workpiece length [mm] | min. 700 |

| Profile depth top [mm] | max. 40 |

| Workpiece overhang [mm] | max. 70 |

| Feed speed [m/min] | 10–32 |

(Previous product name: Postforming machines VF 610)

Software

Brochures