Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

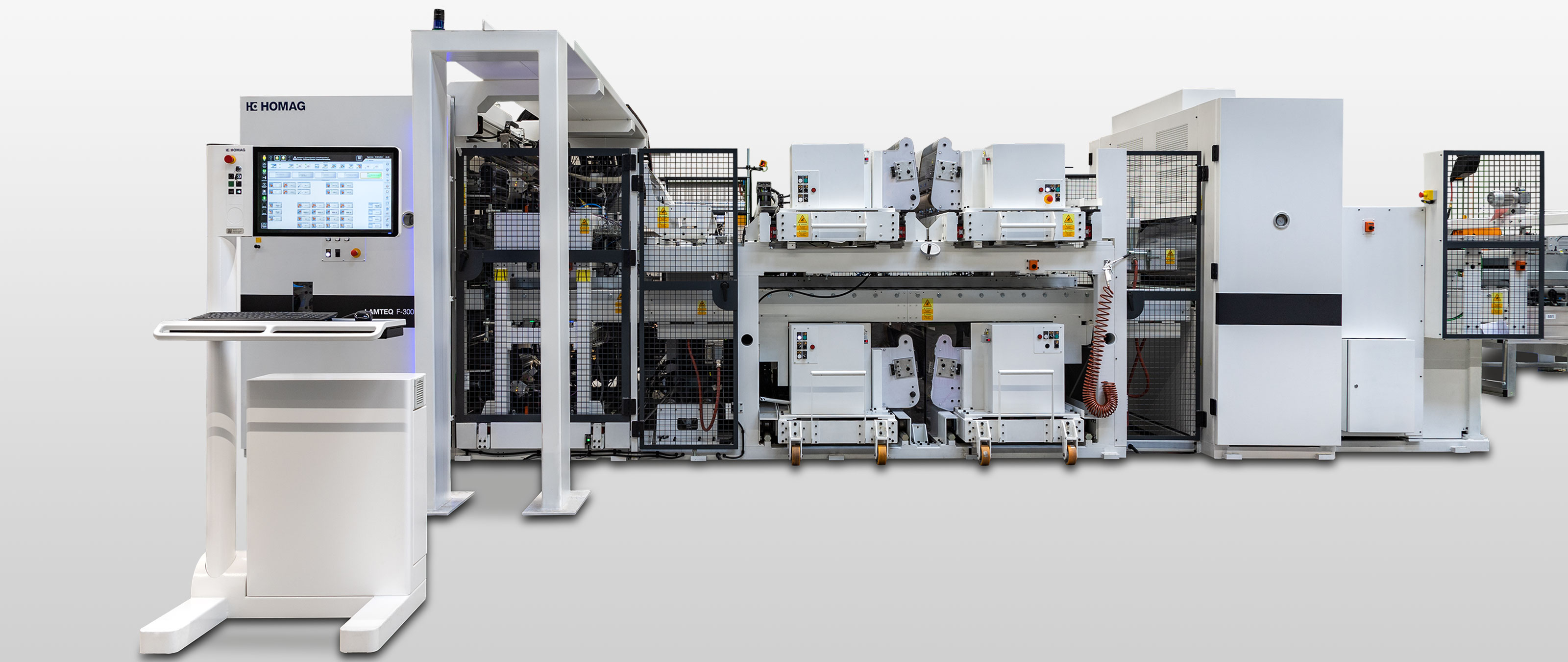

Laminating Machines LAMTEQ F-300

Laminating Machines LAMTEQ F-300

Individual as the demand of your customers

Laminating is experiencing something of a renaissance in the field of decorative finishing of wood-based panels. Major trends such as natural and tactile structured surfaces are raising the bar for surfaces in the furniture industry. Today, technical innovations and continuous developments are making laminating a powerful, flexible, and reliable finishing procedure. Progress made in using hot-melt glues — and in particular, reactive PUR — is replacing entire generations of glues such as PVAc. Improved quality in resistance to moisture and temperature qualify PUR in particular for use as a binding agent between panels and surface films. The different requirements for surfaces in furniture manufacturing demand clever production solutions that can be achieved by utilizing the experience and solid process expertise of HOMAG. HOMAG has aligned and expanded its portfolio on this basis. Customized laminating technology for customer-specific solutions.

Images

Features

-

Single-sided or double-sided lamination

-

Workpiece width up to 1300 mm

-

Glue application via slot nozzle or roller bar nozzle

-

Processing of thermoplastic films, high-gloss and supermatt films, as well as decorative papers all on rolls

-

completeLine: possible combination of surface lamination with wrapping of the workpiece longitudinal edges

-

Laminating system with automatic change of film without interrupting the feed

Brochures