Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

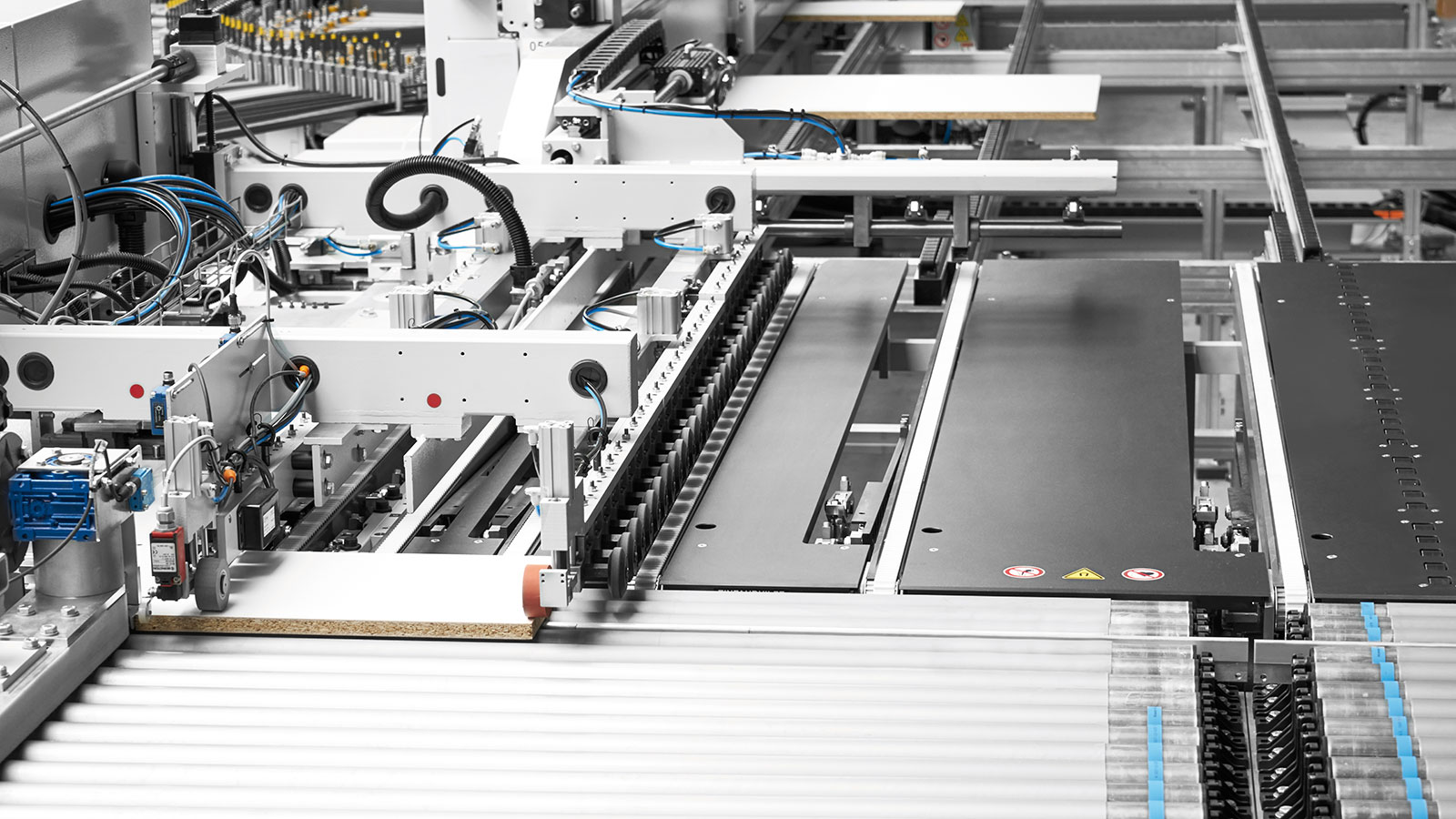

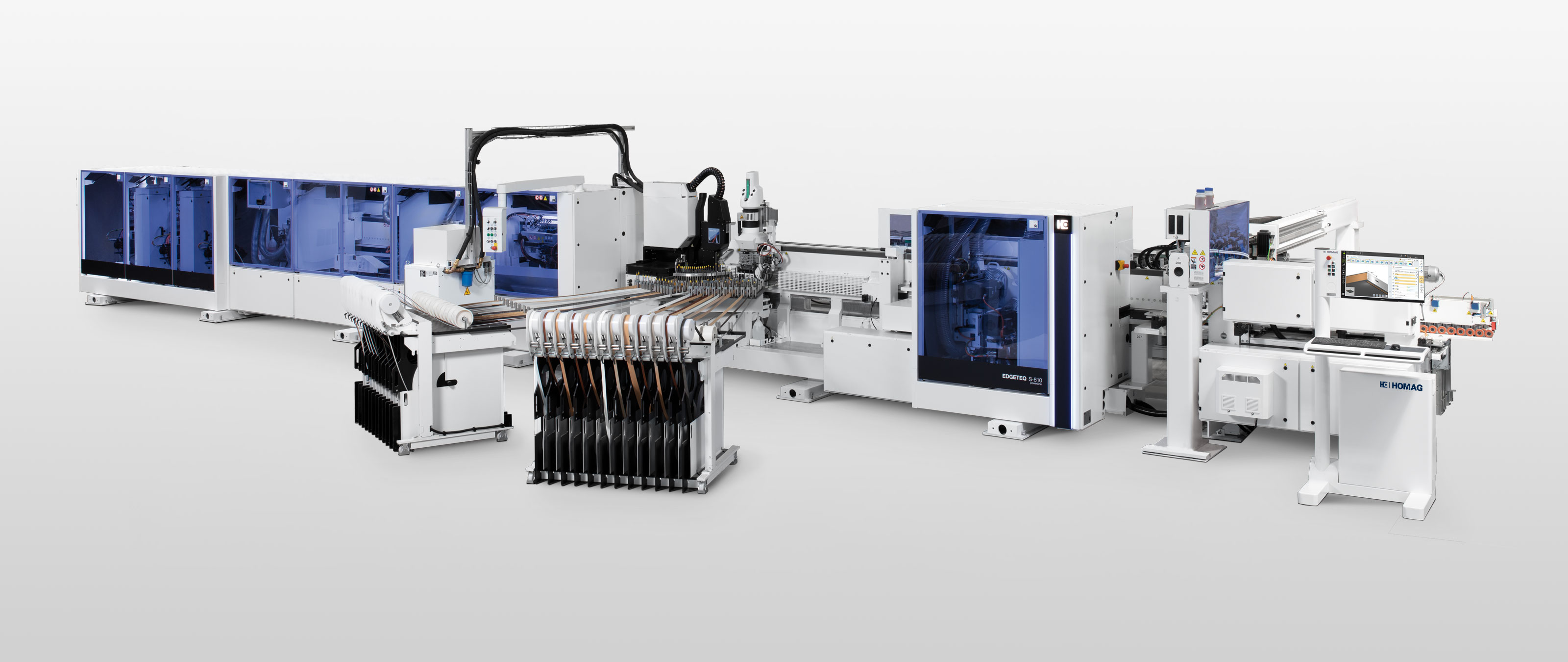

Edge Banding Machines EDGETEQ S-810 powerLine

Edge Banding Machines EDGETEQ S-810 powerLine

Delivering accurate processing and the perfect aesthetic in combination with any edging material

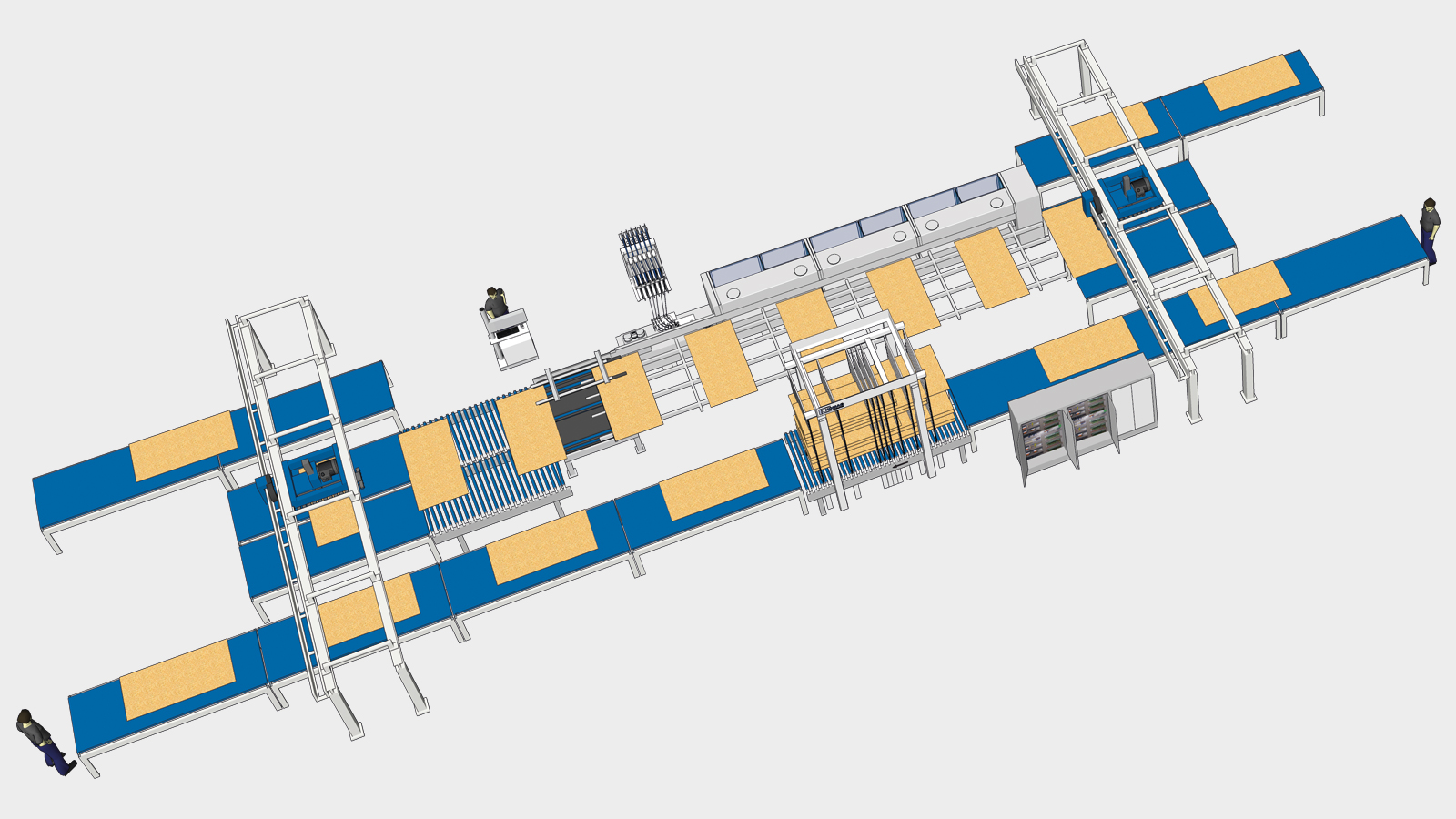

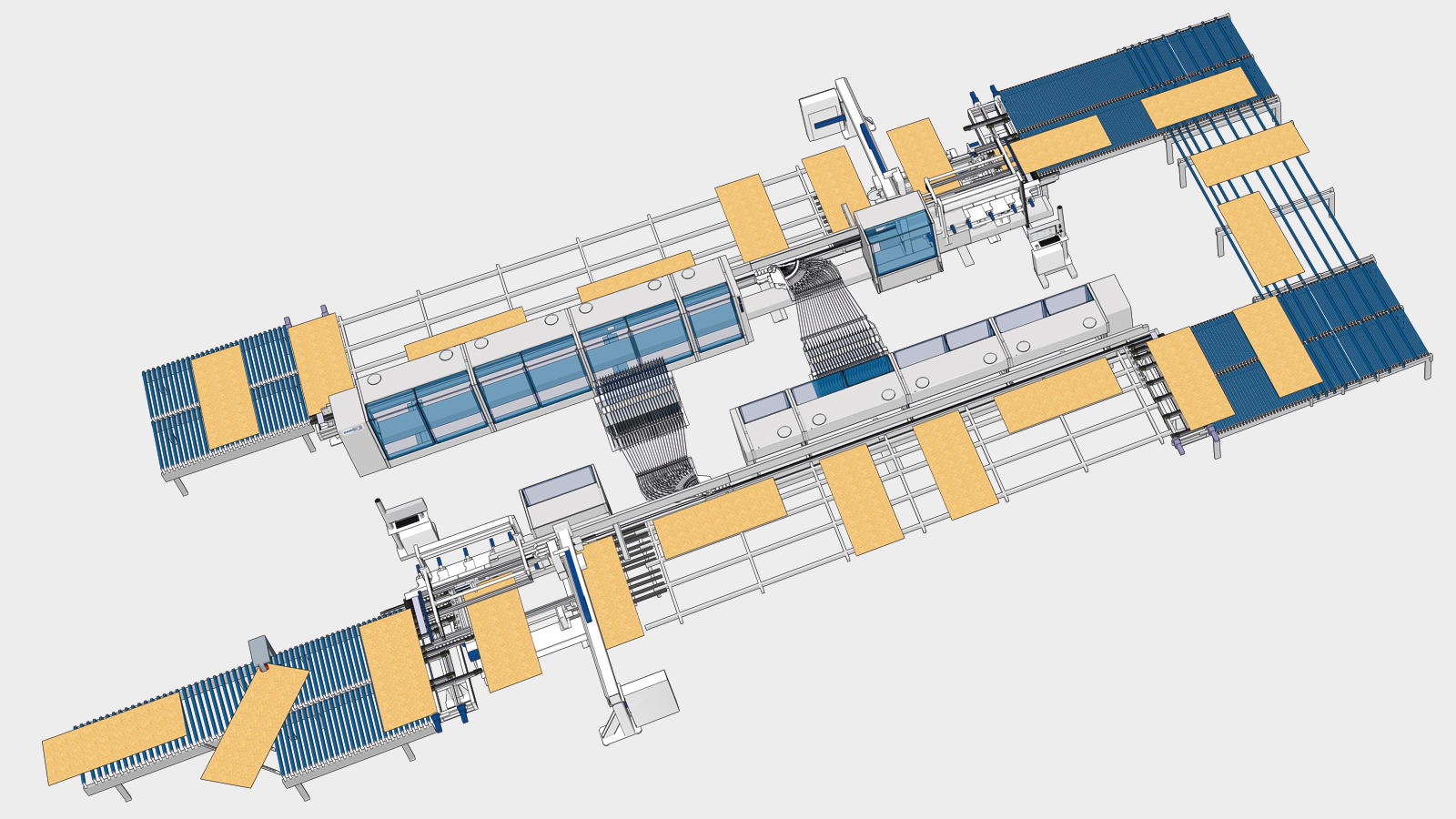

The single-sided machines in the EDGETEQ S-810 powerLine series are ideal for flexible furniture part production up to batch size 1. These machines offer the flexibility for different system concepts to be set up, i.e. a concept that prioritizes precise results, a specific productivity level or a defined performance level per shift. Simply choose the units that suit your individual production needs from our tried-and-tested range of modules.

Images

Features

-

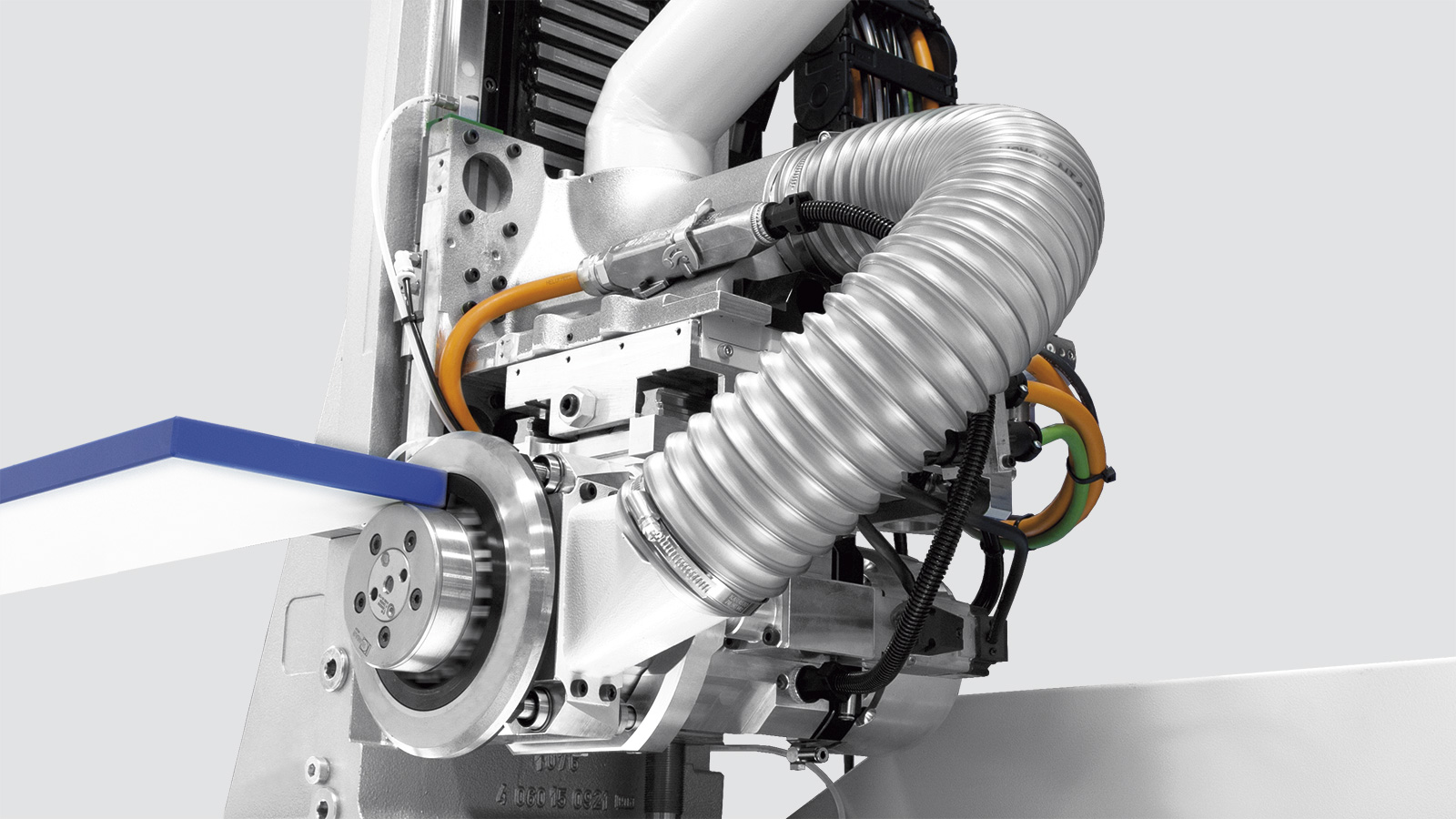

Wide variety of edging materials: Efficient processing is achieved by selecting gluing units with several edging feeds

-

The grooving unit with automatic tool changer enables excellent groove variation

-

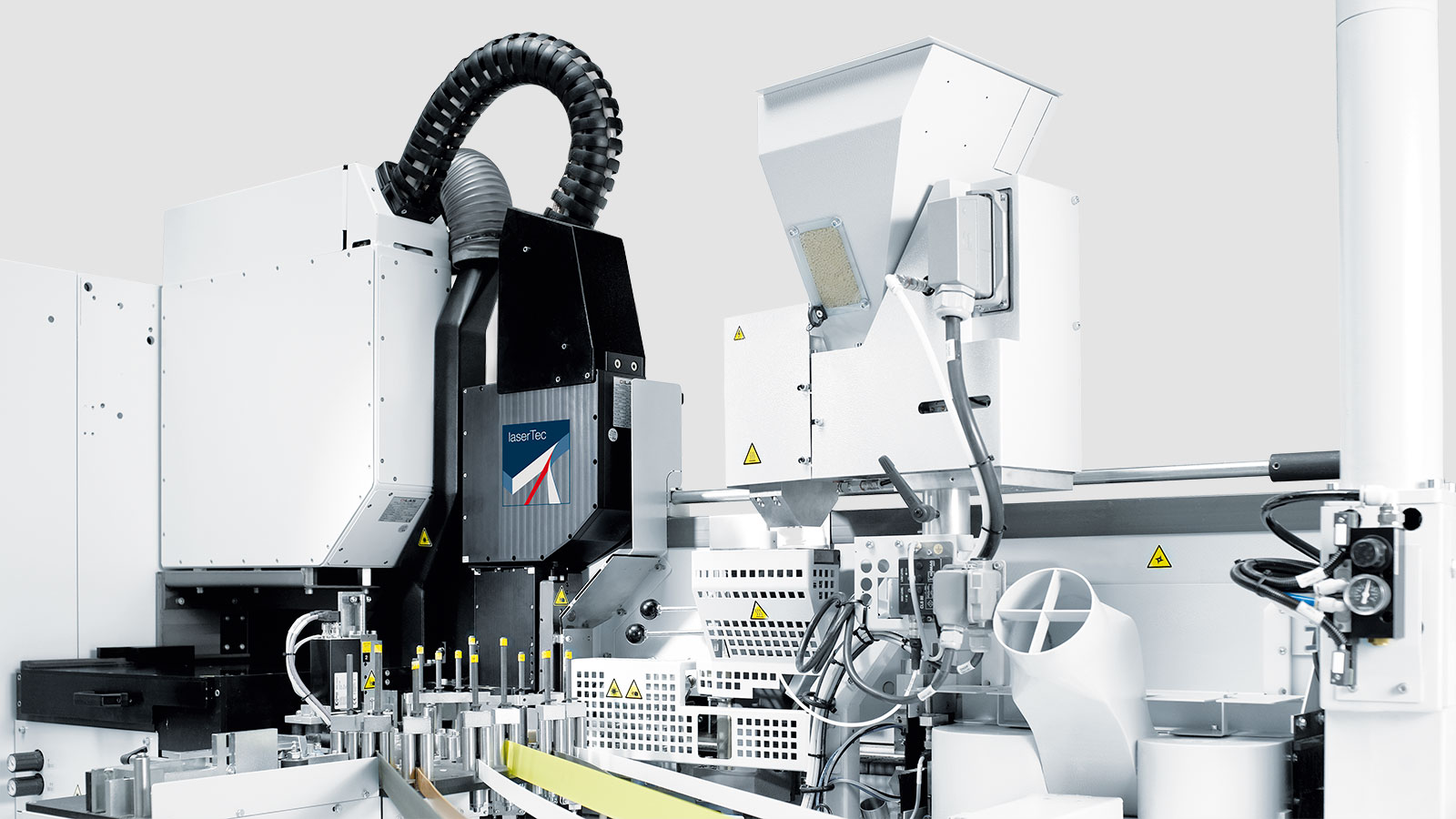

All commercially available edging types can be processed with the HOMAG laserTec technique.

Under patent law in Germany only usable with Rehau edge! -

Compatible transport equipment enables easy workpiece handling in a way that protects the material

-

Low energy costs plus material savings with ecoPlus

Technical Data

| EDGETEQ S-810 powerLine | |

|---|---|

| Workpiece width | |

| with workpiece thickness 22 [mm] | min. 85 [mm] |

| with workpiece thickness 60 [mm] | min. 100 [mm] |

| Workpiece thickness | |

| min. | 12 [mm] (optional 8 [mm]) |

| max. | 60 [mm] |

| Edge thickness coils | min. 0.3 [mm]–max. 3 [mm] |

| Feed speed | 10–40 [m/min] |

(Previous product name: Edge banding and combination machines K 610: Individual equipment configuration)

Here's how your colleagues produce

Brochures