Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

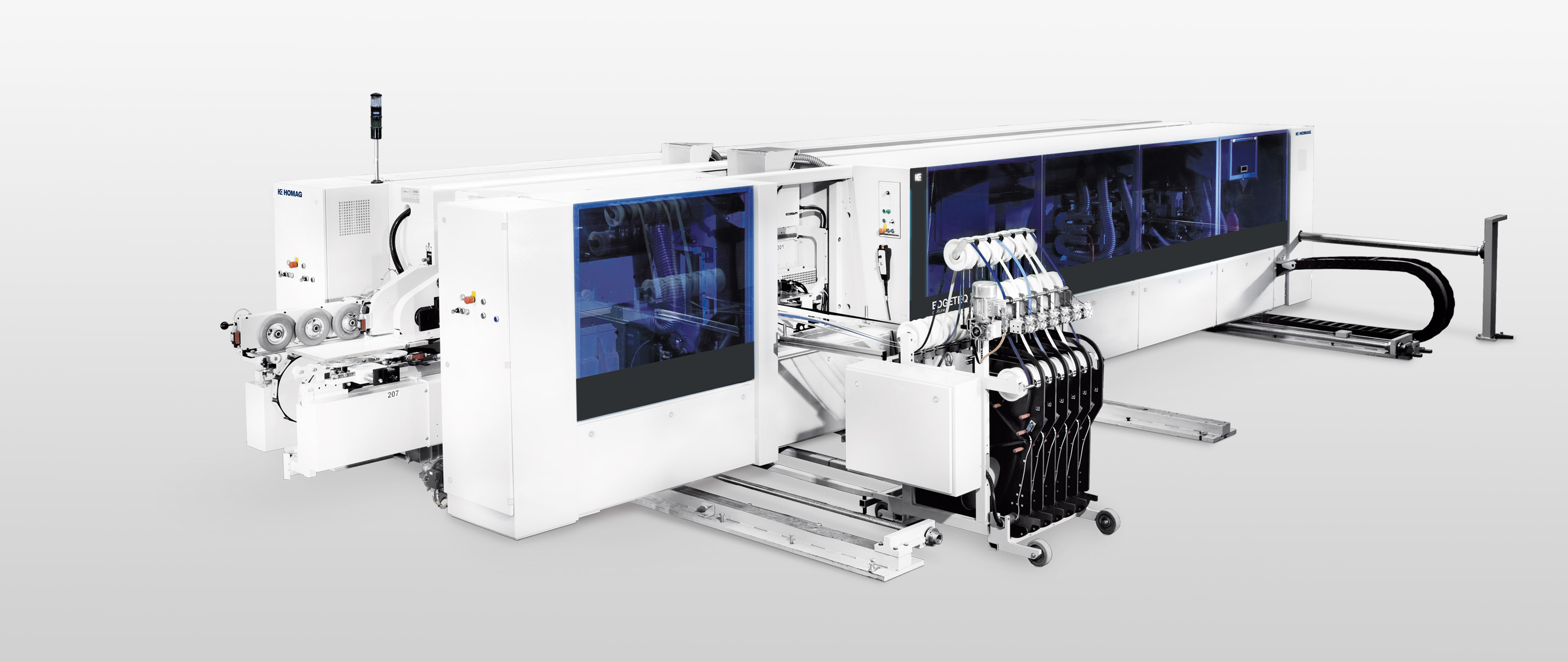

Edge Banding Machines EDGETEQ D-610

Edge Banding Machines EDGETEQ D-610

High-performance machines offering compact to tailored solutions

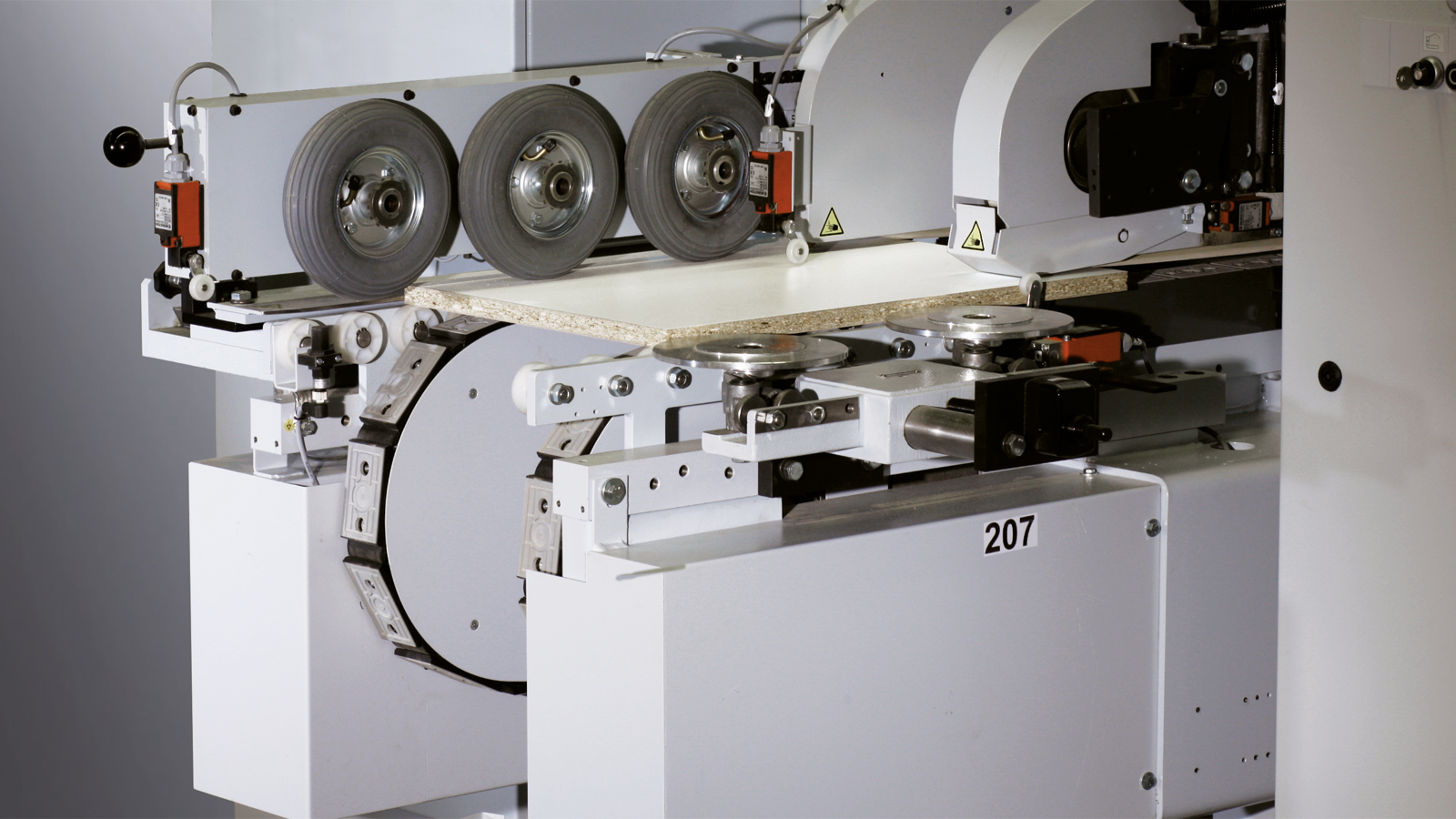

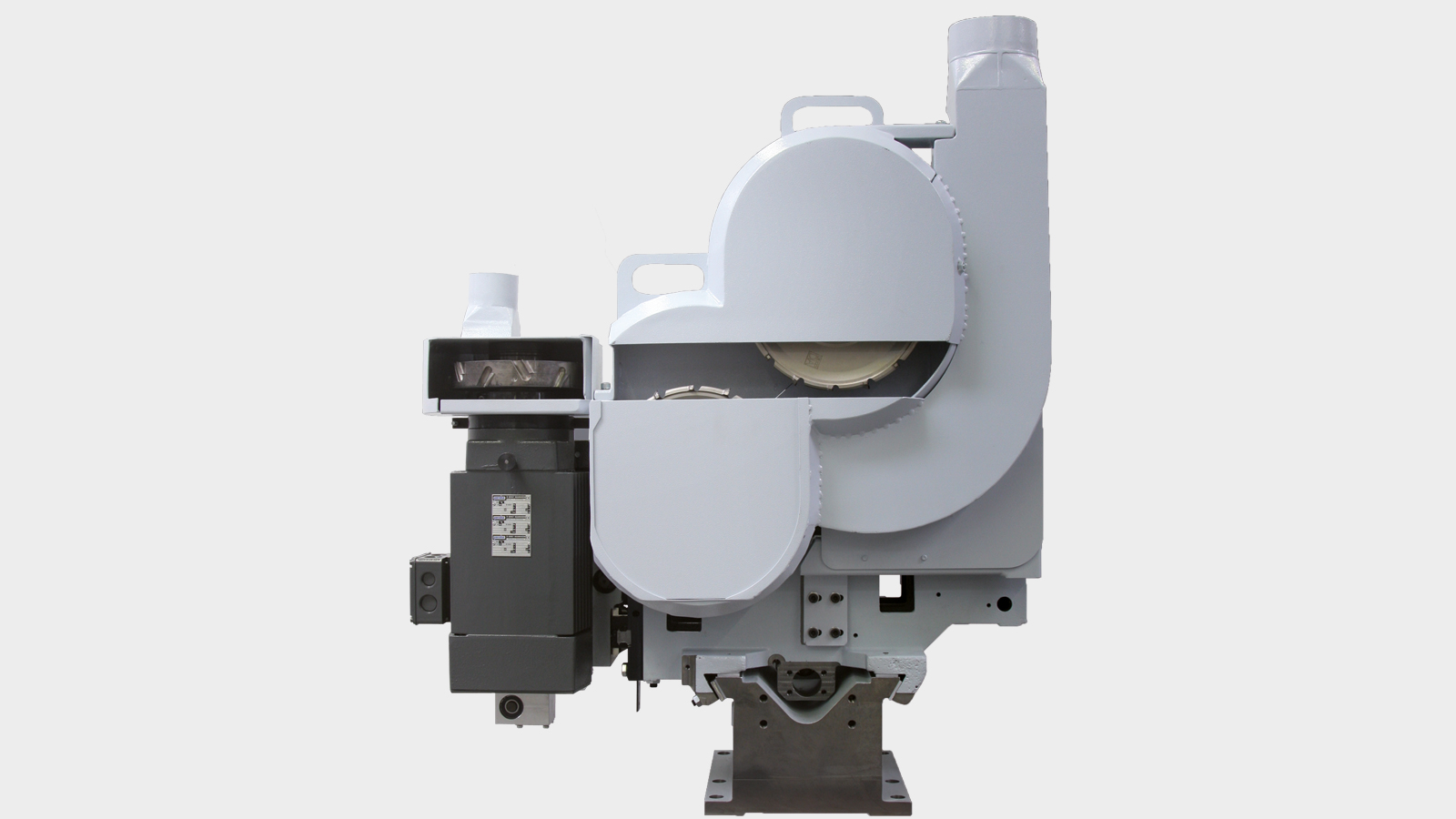

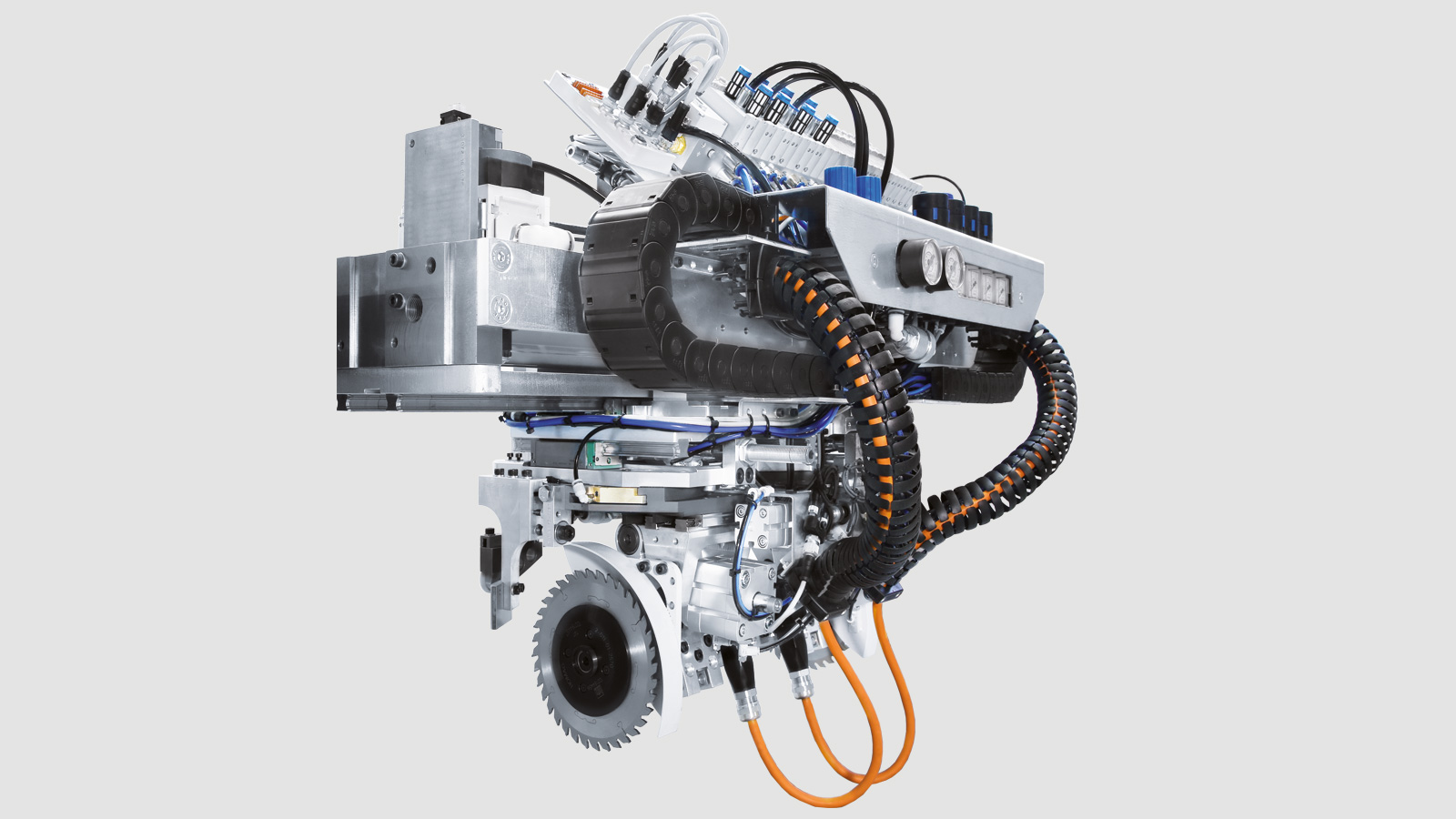

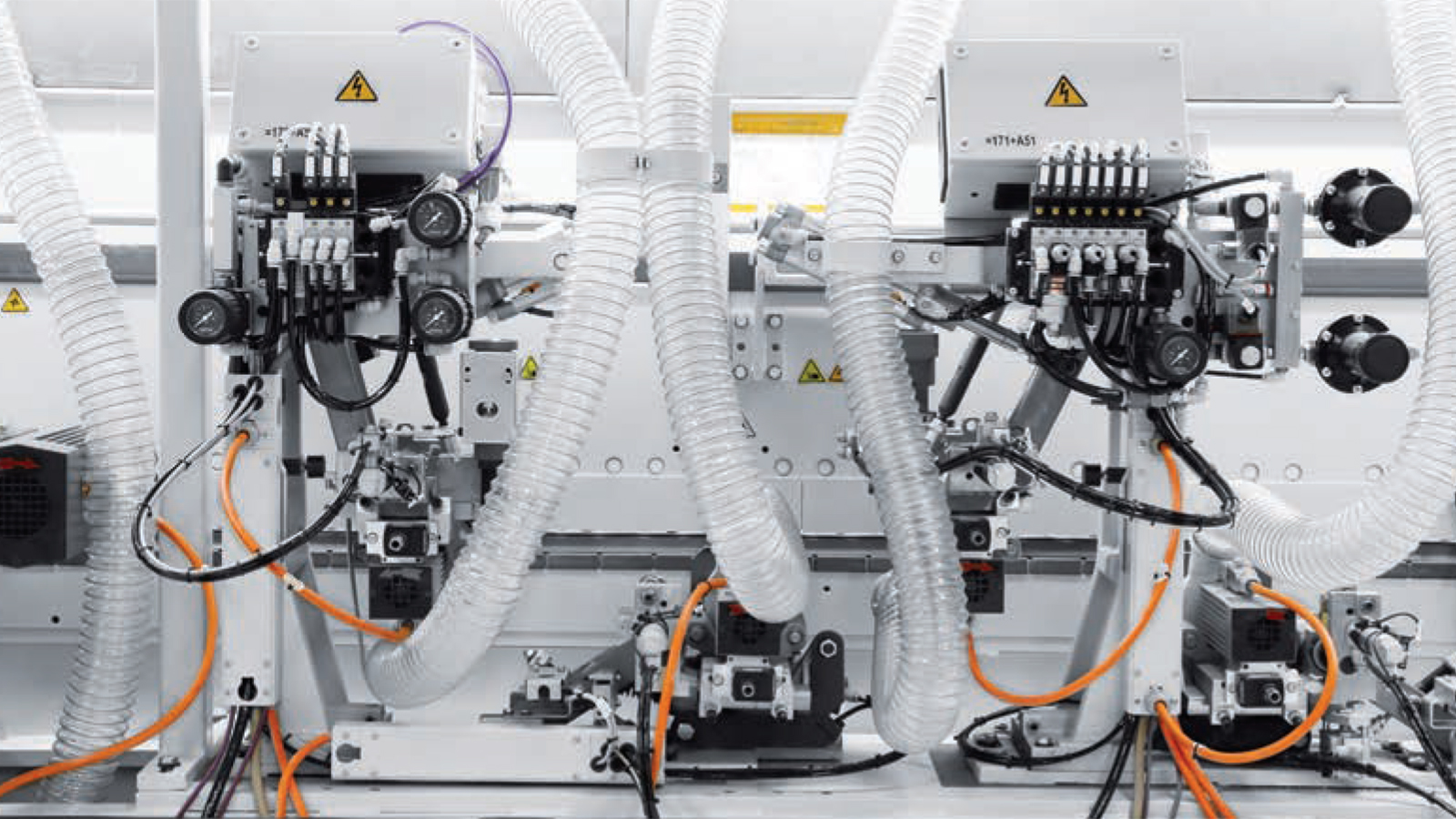

With the EDGETEQ D-610 profiLine series, you can format, profile and edge your furniture workpieces on two sides in a single run. Double-sided machines and machine lines are traditionally used to produce medium to large series at a high performance level with few changeovers.

Images

Technical Data

| EDGETEQ D-610 profiLine | |

|---|---|

| Machine length [mm] | 6,650–12,880 |

Workpiece width [mm] Machines 1 Machines 2 |

min. 195 min. 250 |

Workpiece thickness [mm]

| min. 12 (optional 8) max. on request |

| Edge thickness coils [mm] | min. 0.3–max. 3 |

| Feed speed [m/min] | up to 50 lengthwise |

(Previous product name: Edge banding and combination machines K 520 optimat and profiLine)

Here's how your colleagues produce

Brochures