Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

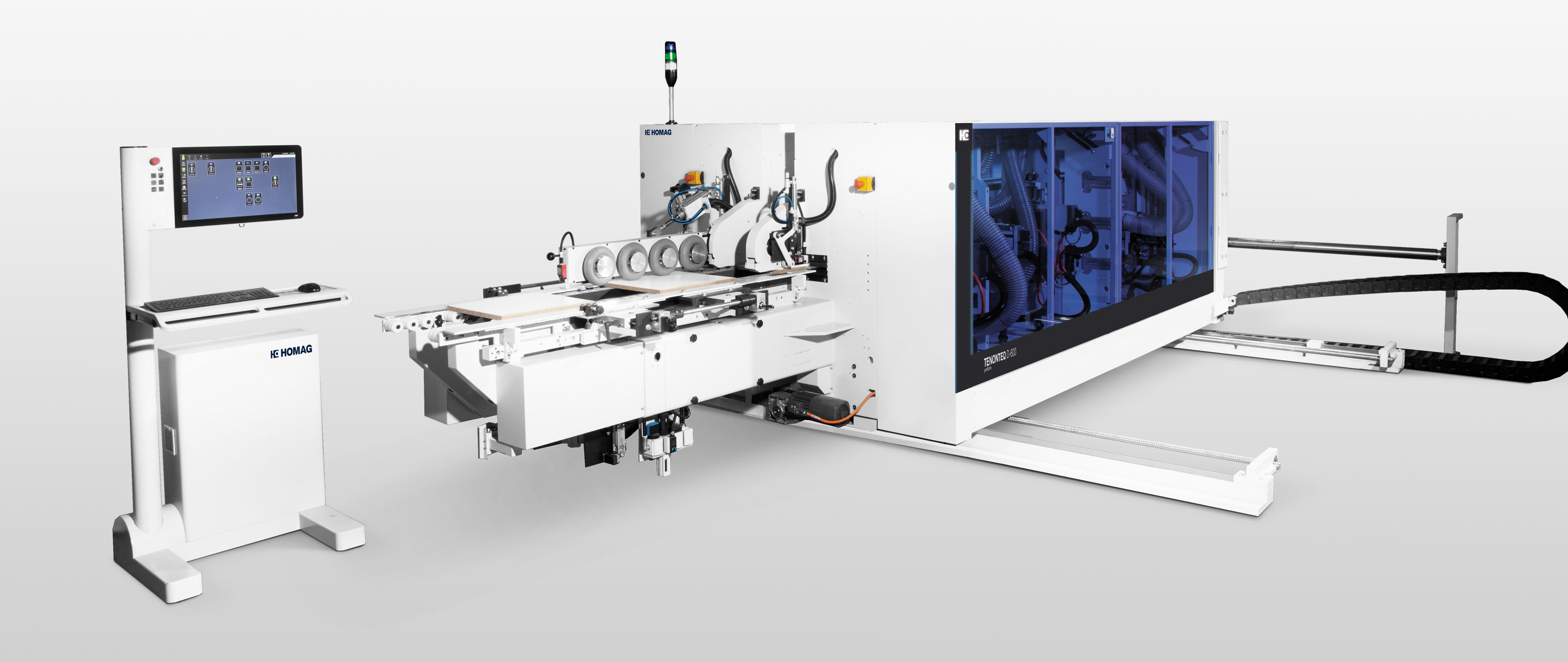

Double End Tenoners TENONTEQ D-600

Double End Tenoners TENONTEQ D-600

Two throughfeeds - longitudinal and crosswise - process the four sides of your workpieces

Angle cuts, sizing, profiling, rabbeting and grooving: The double-end profiler offers a range of different capabilities, as well as being a robust and reliable machine that can deliver precisely finished workpieces in large quantities. You can massively increase your production capacity with two machines in sequence.

Images

Features

-

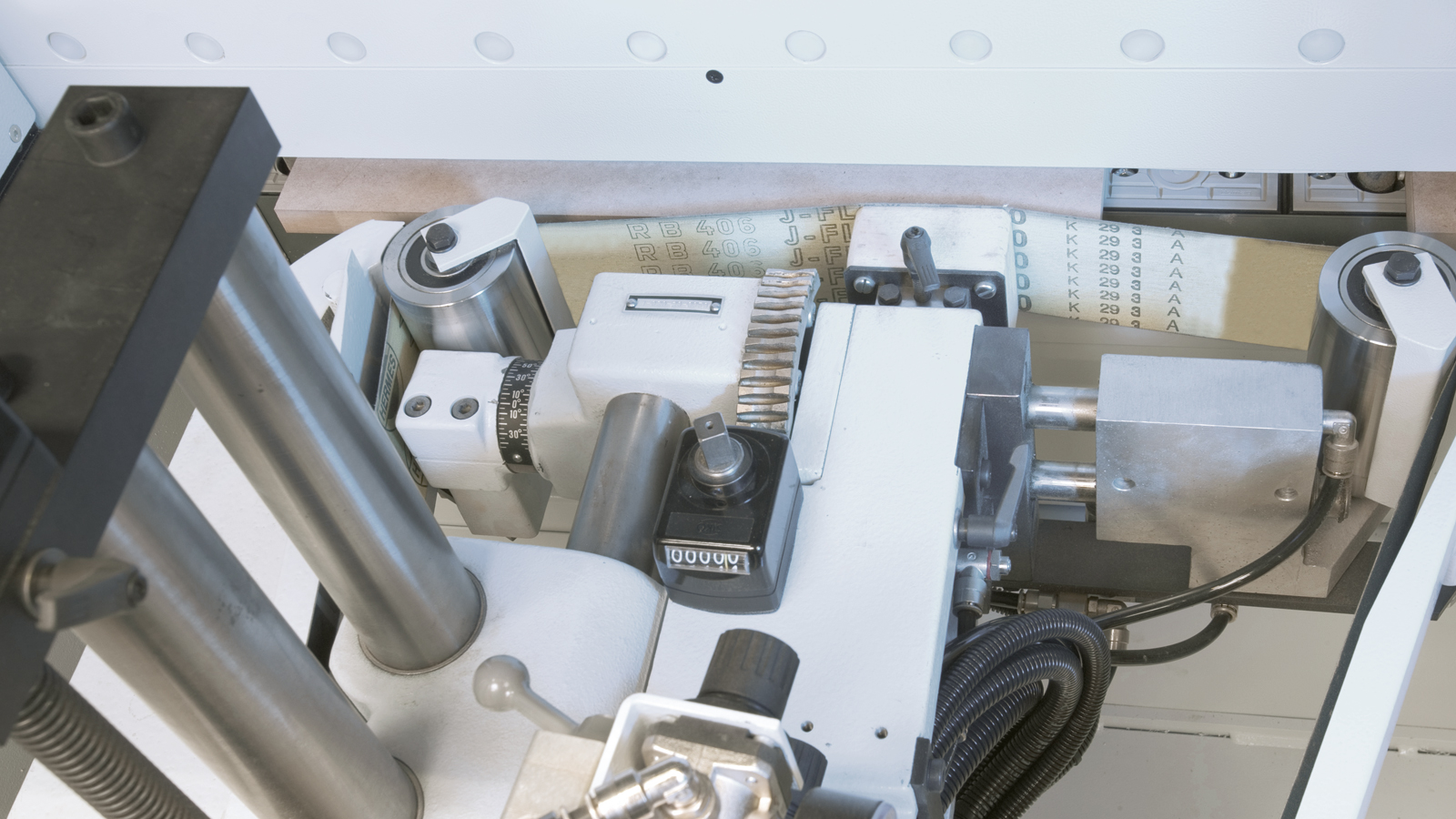

Scoring and chipping unit for tear-free processing of coated surfaces or clean cross processing of veneered parts and solid wood

-

SF20 standard trimming unit for precise trimming of grooves and rabbets within the machines without the need for an additional processing step

-

PS10 profile sanding unit for sanding profiles and straight edges with a large belt length, two belt speeds, swivel range of 30° upwards and 45° downwards

Technical Data

| TENONTEQ D-600 | ||||

|---|---|---|---|---|

| Machine length [mm] | ||||

| FPL 525 | 3,650–7,650 | |||

| FPL 526 | Individual machine | 4,650–8,650 | ||

| FPL 526 | Line execution | 4,880–8,880 | ||

(Previous product name: Double-End Tenoner FPL 520: for manufacturing doors, fronts and panels)