Easy machining: Use data smartly

"Easy machining" represents the combination of tools, materials and the machine. All three components communicate with each other consistently. The result: Data is combined and used intelligently and interactively, making your day-to-day work even easier going forward.

- Is the creation of new items (e.g. panels or edges) becoming too complex?

- Is searching for the right tool for the next work step too time-consuming?

- Don't have an overview of your edgebands or know how much stock is still available?

- Do you consume unnecessary material when trying to find the correct setting for your machine, or use up excess time that might be better spent elsewhere?

With "Easy machining", these questions are a thing of the past.

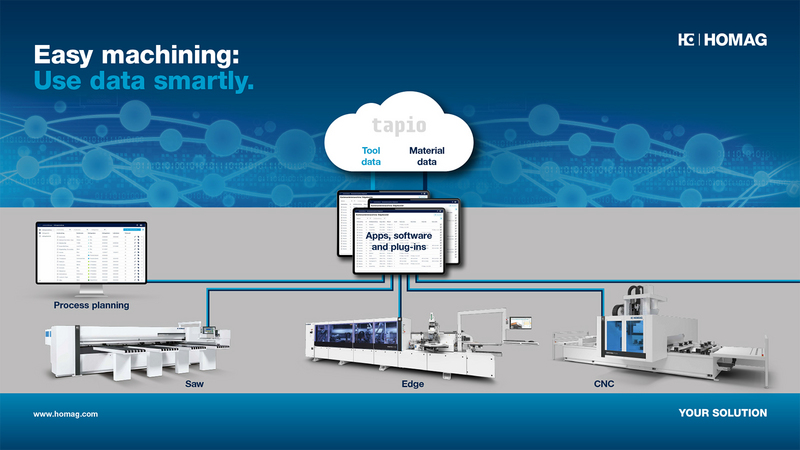

How "Easy machining" works

In the first step, data is provided via tapio. In particular , this involves tool and material data. Tool data from LEUCO or AKE, for example, or material data in the form of panel and edge data from EGGER, REHAU or Ostermann is available digitally.

Wondering how that works? The tool and material data is accessed easily via tapio, is automatically available in various HOMAG digital products and machines, and can be used consistently without additional effort.

This is not a one-way street — your machine returns the residual length of an edgeband or the tool service life. If the tool is blunt, you can commission a sharpening service with one click. After sharpening, the digital tool operation card is updated with the current measurement data. This is what "Easy machining" offers.

The automatic provision and integrated use significantly reduces the manual creation of tool and material data. Data that you have added in the tool or material management during work preparation is automatically available in your machine. For example, thanks to the interaction and flexible combination of your data, automatic parameter suggestions for material and tool combinations for adjusting the machine are provided by HOMAG, which is crucial during a shortage of skilled workers. Your machines access the same data in a uniform way and use it without any manual intermediate steps.