Founded in 1998, Preston based Fern Doors produces a range of high quality made to measure doors for fitted furniture manufacturers. Based in two units, Fern Doors’ facility covers a combined total of 1,300 sq. ft. with 20 staff members. Dealing exclusively with trade customers, its range features a variety of materials and colours for custom-made kitchen and bedroom furniture.

As the demand for its bespoke fitted and sliding wardrobe doors increased, Fern Doors decided it was the right time to upgrade its production process.

Phil Philipson, managing director at Fern Doors explains: “We were seeing increases in both the volume of production and the size of the doors we were producing. It soon became obvious that our existing edge bander could no longer keep up with demand and to make matters worse, we started to face reliability problems as well.

“In addition to this, our existing return system no longer met our needs. For one thing, it wasn’t big enough and it also did not turn long panels on the far end after they had been edged. This meant we needed an additional operator to manually turn the doors so that they could begin the edging process on the opposite edge. With 80 per cent of our manufacturing work being large wardrobe doors, this was proving to be very time consuming and was slowing down production.”

Looking for the edge

“We started our search for a replacement machine by looking at a couple of the popular edge bander manufacturers. However it was proving difficult to find a solution which not only matched our requirements but was also the right size for us. A couple that we looked at were either too small or too big – there was no suitable medium size. This was an important factor for us because we are limited on space at our facility.

“We knew that HOMAG not only had a reputation for being the market leading woodworking machinery provider but also for its pioneering edge banding technology. After contacting HOMAG UK the area manager, Jon Lawman, invited us to visit the Castle Donington showroom to look at its edge banding solutions.

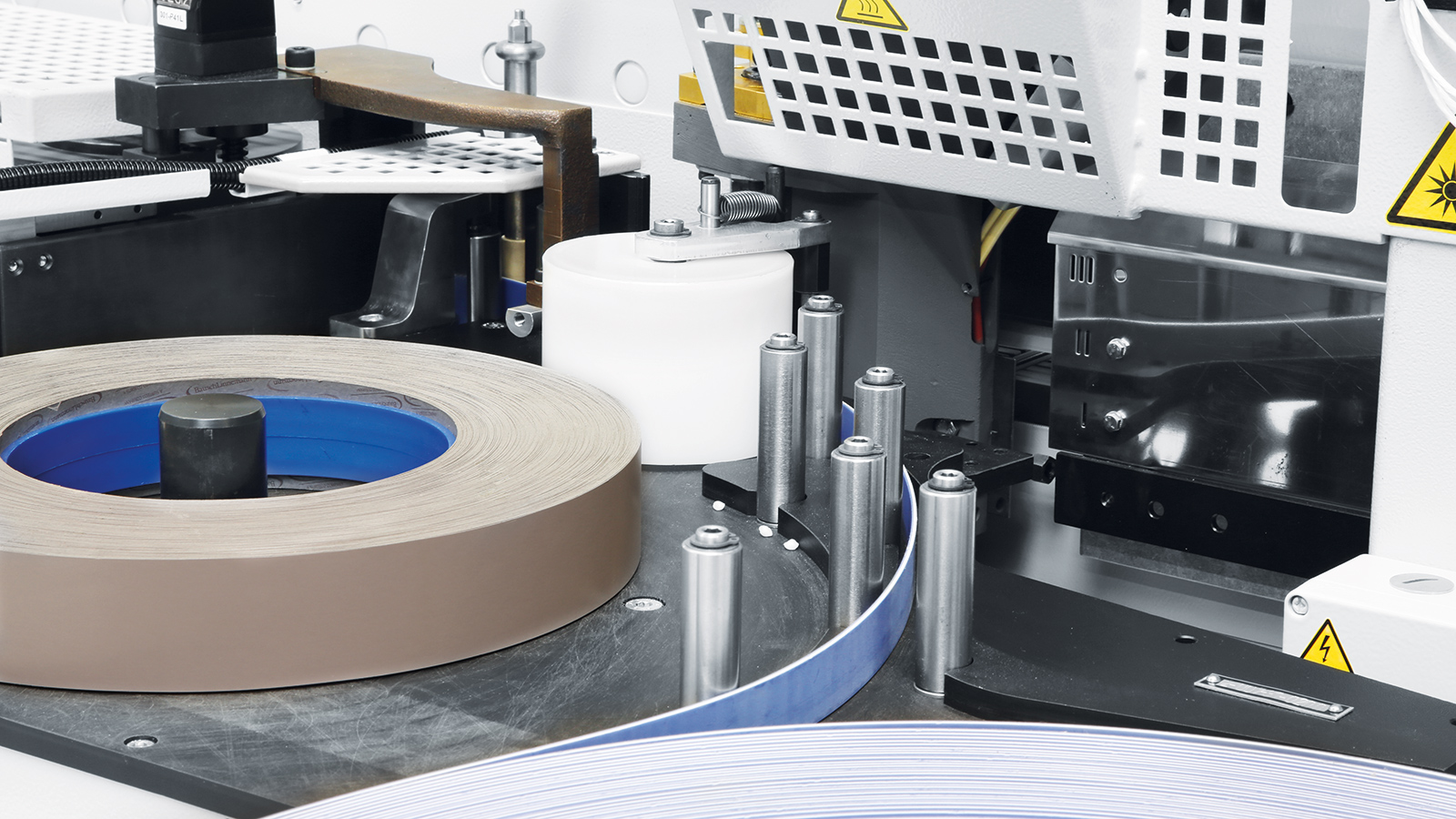

“We did visit another factory first, but failed to have our requirements met so we went straight to HOMAG UK that same day. Right from the start Jon was very upfront with us and didn’t try to baffle us; he listened to what we wanted. We explored a couple of HOMAG’s options before placing an order there and then for a HOMAG KDF 670 airTec edge bander with a BOOMERANG® TFU 140 return system. Not only had we found a system that met our exact requirements, but also we were impressed by both the speed and the build quality of the HOMAG machine.”

A seamless installation by HOMAG

“The installation process ran very smoothly. The machine was delivered and up and running when HOMAG stated it would be. Our operators received in-house training when the machine was installed. They have found running the edge banding return system extremely easy. And as for the KDF 670 itself, the powerTouch control screen makes production very straightforward.”

A new lean and efficient production process

“The HOMAG KDF 670 has not only sped up our production process, but also improved our edge finishing. Even though we mainly use PUR glue, we were very keen to have the addition of airTec on our new machine. It means we are able to offer an additional edge sealing option for customers requesting an invisible joint. Similarly, the PUR gluing system on the new edge bander is producing a far superior finish quality on PVC doors than our previous machine.

“The new return system has reduced our edge bander from a two-man process to a one-man operation. We no longer need an additional pair of hands to turn edged doors round as this system is well equipped to do this. Not only has this saved a tremendous amount of time but it has allowed us to move the surplus worker to a more productive role in the workshop.

“As we expected from its reputation, the HOMAG edge banding system is extremely reliable. We run the machine every day for at least eight hours. The only downtime it sees is when the operator goes for lunch break.”

HOMAG – a manufacturer who cares

“What I really like about dealing with HOMAG is the superior after sales support. Since the installation was completed, we have received several calls from HOMAG checking the system still meets our expectations. On top of this, we know that if we ever have any problems, there is always someone willing to help on the other end of the phone.

“We took advantage of HOMAG Finance to purchase the new equipment and the team made the process very easy. The machine has sped up production so much that I expect the system will pay for itself within the next five years. It was definitely money well spent,” concludes Phil Philipson.

If you would like more information or a demonstration of the latest HOMAG edge banders or return systems please contact HOMAG UK on 01332 856424.

“What I really like about dealing with HOMAG is the superior after sales support. Since the installation was completed, we have received several calls from HOMAG checking the system still meets our expectations. On top of this, we know that if we ever have any problems, there is always someone willing to help on the other end of the phone.”Phil Philipson, managing director at Fern Doors