You all know it! Complex projects for digitizing individual processes or complete process landscapes. There are enough examples for resource-consuming and lengthy introductions to the digital mapping of business processes. SCHULER Consulting offers new approaches to simplified process digitization for a wide variety of corporate areas. Imagine you can use an app to digitally map one of your company-specific processes in the twinkling of an eye and thus easily handle an otherwise complex implementation.

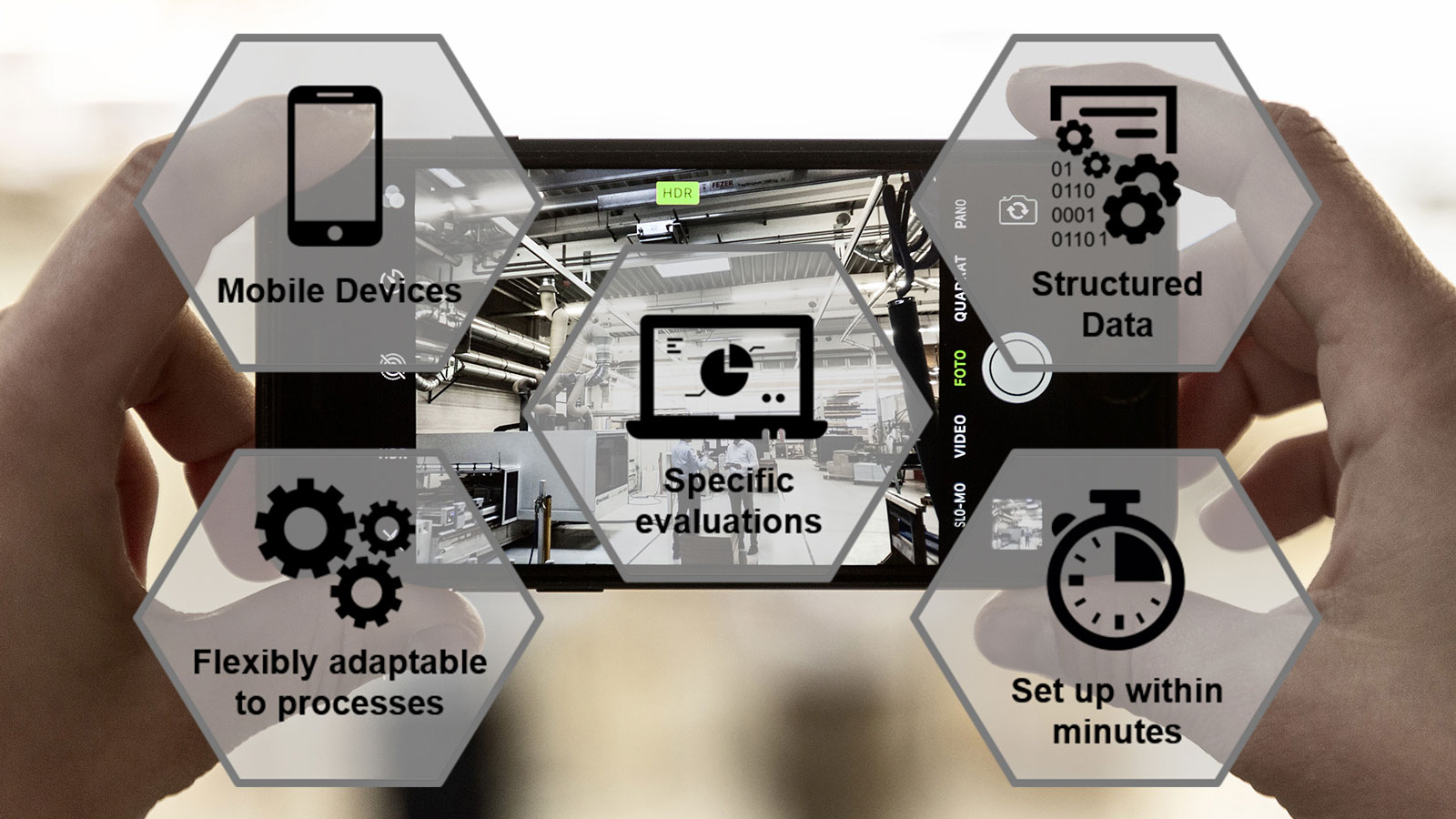

Today there are apps for almost everything. The creation of customized apps is no longer a major obstacle and, if flexible customization is guaranteed, can bring enormous advantages in the collection of production-specific data. Gone are the days when you had to bind well-trained employees to data gathering for many days. A flexibly configurable app enables new approaches to digitizing your processes. The fields of application of data recording with the app range from simple feedback to complex time recording. In contrast to conventional procedures, this mobile variant also allows the introduction not to have to be planned down to the smallest detail. Already after a rough planning within a few minutes a functional data acquisition can be set up and tested. This ensures at an early stage that the necessary data can be captured, which in many projects is not taken into account at all or only at a late stage. Subsequently, data processing can be set up on verified live data. This is all the more valuable, since a large part of the problems is revealed very early in the course of the project through the use of real data.

By using an app, workflows from various function modules can be configured and used promptly. In this way, individual functionalities adapted to the operational processes can be set up in the app and distributed to the mobile devices within minutes. For example, parts can be identified by barcode or QR code scan and their quality confirmed in the next step. If the quality is then insufficient, the further procedure can be recorded. And completeness and quality control are already completed in a single operation and completely independent of location. Thus a simple but effective digital process mapping is realized. The recorded data is stored in the cloud. In order to further process this data, a wide variety of options are available. From direct integration of the data into the company's own ERP to simple visualization and evaluation in Excel. The possibilities are as individual here as they are for data collection. This is just one of many specific applications. Much more complex processes can also be mapped, as the following practical example shows.

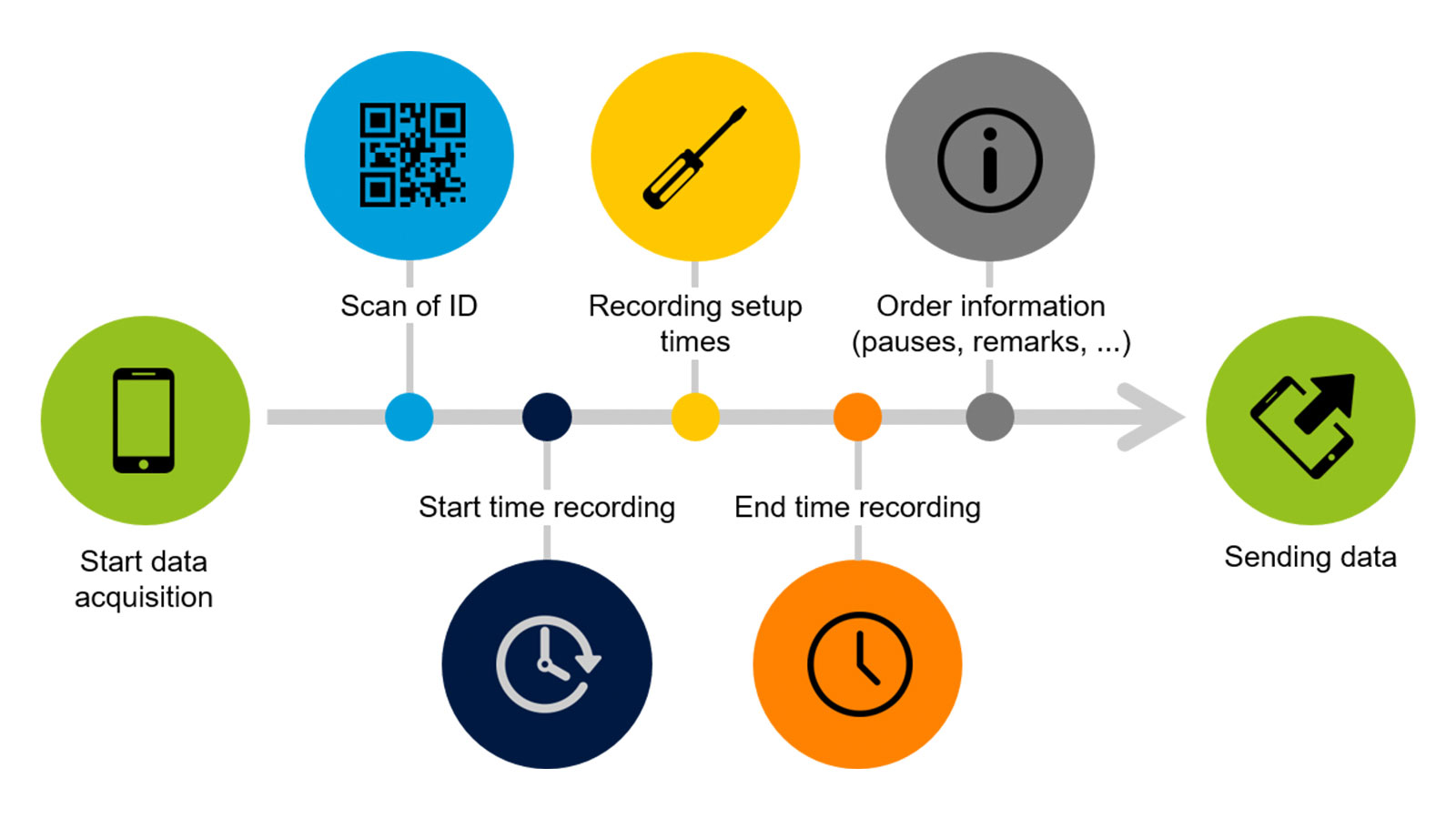

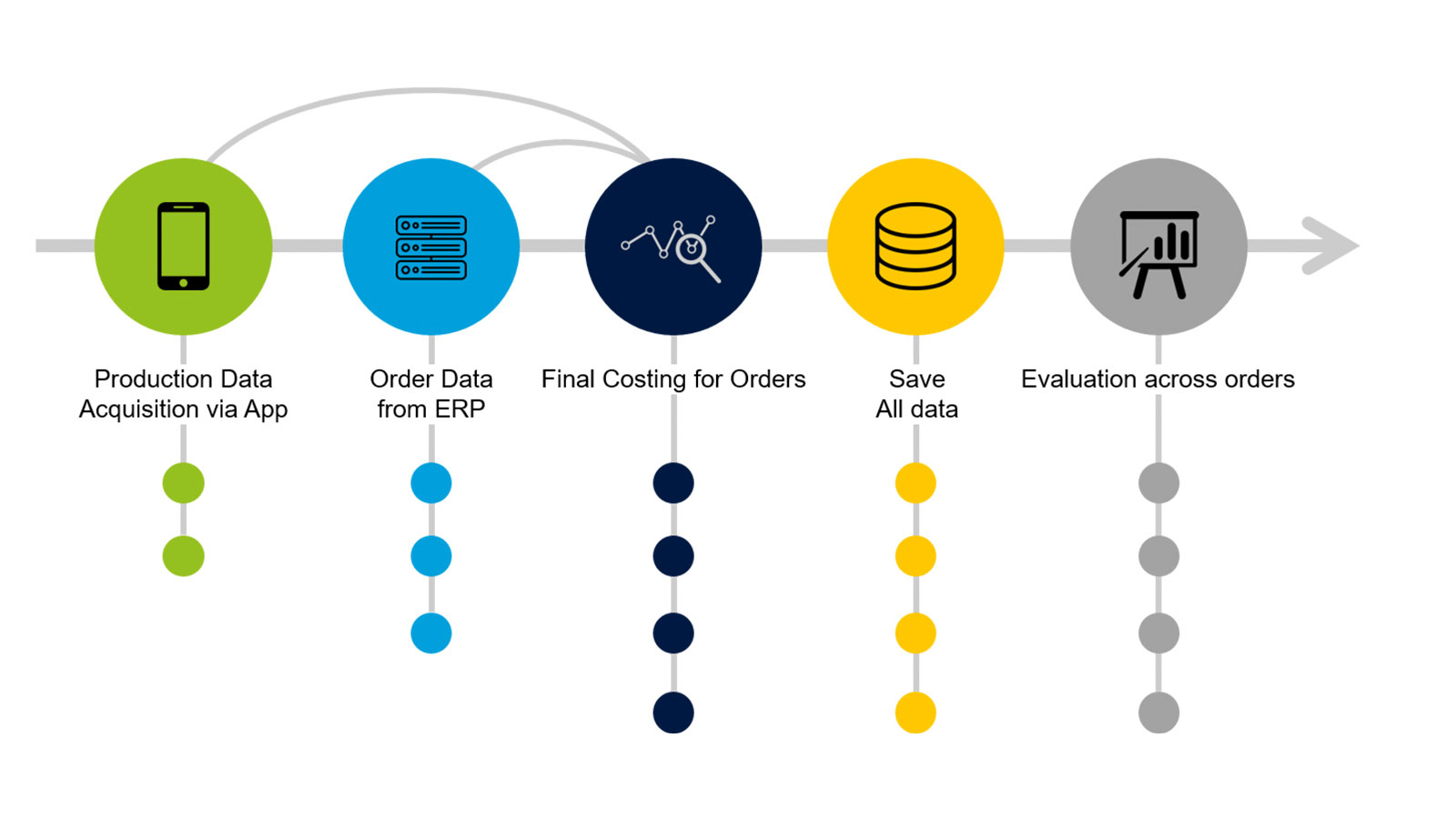

The well-known front manufacturer Reichert Holztechnik GmbH & Co. KG in Pfalzgrafenweiler has been working successfully since this spring with an app developed for him and uses it throughout the entire production process for recording production data. In this application, it was important to implement a meaningful post-calculation promptly. On the one hand, individual orders are evaluated in detail for efficient and inefficient work processes. In addition, a key figure calculation is automatically calculated based on overall order times and materials. To do this, the employees first record times for each operation using the app. This is done flexibly and uncomplicated according to the scheme: "Barcode scan → Start → Stop → Time recorded" via smart phones in production. Further details such as set-up times on the machines or other order information can also be recorded at various workstations. Together with detailed order data from the ERP system, attractive charts can be generated at the click of a mouse. Each order can be evaluated in detail with times, material and corresponding costs. This enables the company to check orders and entire product lines for cost efficiency the first time. The prepared data is then stored in a central repository. This allows the cross-order determination of key figures at the level of each operation. The data calculated in this way are used as standard values in the preliminary calculations of the products.

Data capture via smart phone or tablet brings the obvious advantages of location-independent and mobile working. Far greater advantages, however, are the low implementation and hardware costs. The latter were almost completely eliminated by customers calling for used smart phones. Data transmission takes place via the company's Wlan network, which makes a SIM card just as irrelevant. The storage of company data in a cloud is often a delicate matter although the platform used is designed according to the new DSGVO (GDPR) guidelines. The fact that the recorded data does not contain any specific knowledge relevant to operations is very promising. Only with the combination of data from the ERP and further processing do company sensitive information emerge. However, this process takes place in the company's own environment.

The fast creation of a process-specific app allows further areas of application. SCHULER Consulting also uses the app during consulting projects to access real data in non-digitized processes. Processes can be modelled and evaluated on the basis of structured data in order to obtain complete business data analyses. In other industries this is known as "Process Mining / Business Intelligence".

This enables companies and SCHULER Consulting to digitize processes within a short period of time. Be it to prepare one-time data for strategic decisions or to digitally map processes in the long term and to build up your company-specific "Manufacturing Cloud". We are convinced that many of today's analog work processes offer themselves to be digitized in an uncomplicated way.

Author: Luca Föhn, SCHULER Consulting GmbH

An article of the trade magazine HK, issue 5/2019. Here you can read the HK Magazine online.

“We quickly got something that's got rhyme and reason without investing much manpower that we don't have right now.”Jürgen Gaiser, Technical Manager Reichert Holztechnik GmbH