New options, perfect edges, extremely simple programming

From the outside inconspicuous, from the inside completely new. 30 years of experience combined with completely new technologies are taking CNC gluing technology to a new level.

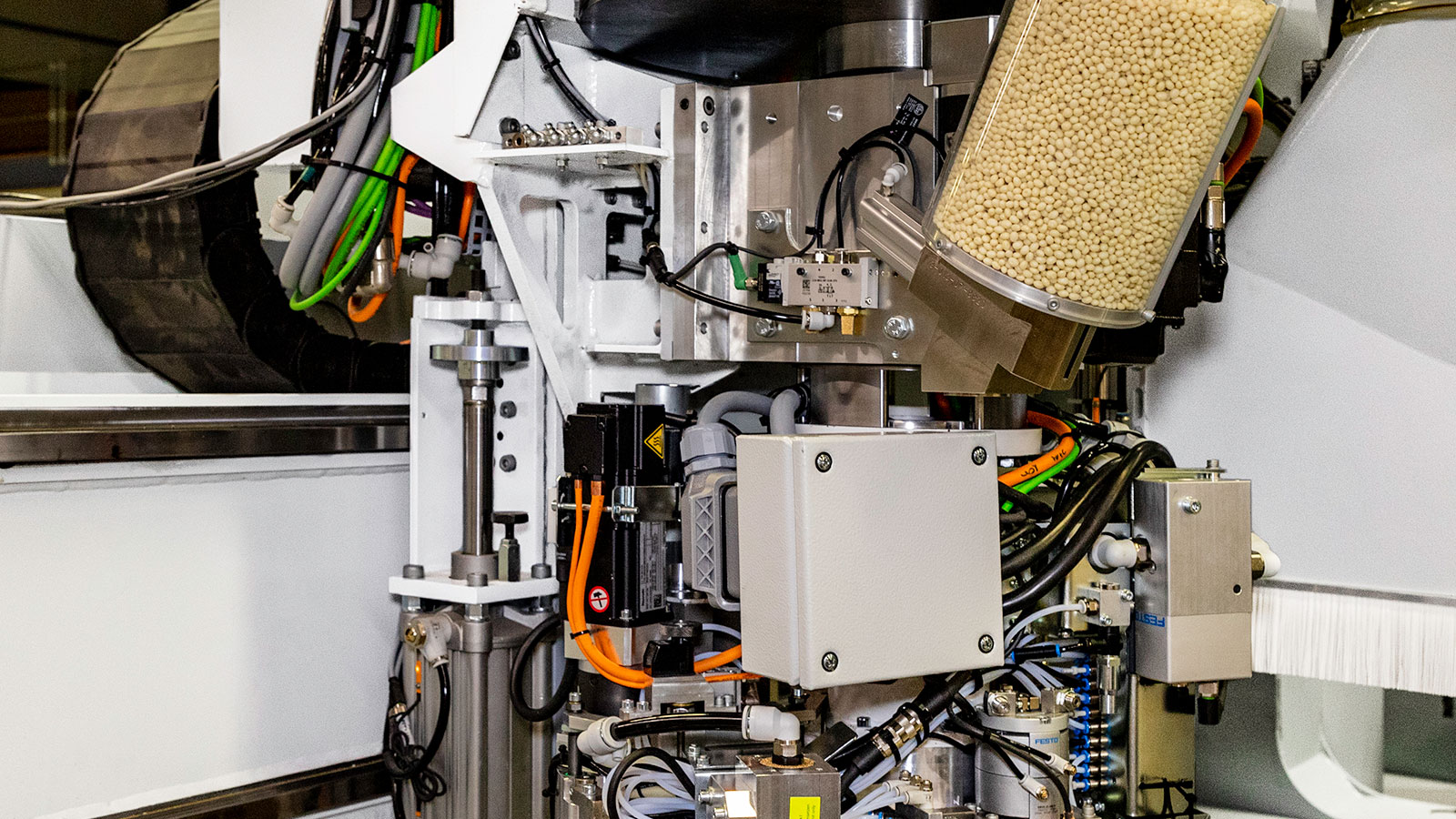

The new powerEdge Pro Duo has the same basic components as previous units: edge transport, edge snipping, glue application and reactivation/rewarming. However, if you look more closely, every component has been redesigned and equipped with the latest sensors and new control algorithms, making it easier than ever to get the perfect edge, even on challenging shapes. And this is possible for all gluing processes.

Overview of the highlights:

- Intelligent control system: defined speed, temperature and contact pressure at every point on the contour. In most cases, no manual fine adjustment of the parameters is required.

- Edge positioning and 360° gluing: the start and end of the edge are positioned precisely, even with a true batch size 1. This enables 360° gluing, even on the smallest components.

- Genuine combined function: zero joint or hot-melt glue application? The unit can do both, with no conversion required. The hot air nozzle for reheating the hot-melt glue also activates the functional layer of a zero joint edge.

BM asks some questions

Questions to Manfred Weid, at Ackermann

What was the reason for investing in a new CNC machine?

Originally, we wanted to extend capacity to ease the load on the existing machine. A low-priced second-hand machine or demonstration machine was also an option.

Why did you decide on a machine with the new powerEdge Pro Duo?

HOMAG asked us if we wanted to be a prototype tester with this gluing unit. Then they presented the new possibilities. We have many years of experience in CNC gluing, so the advantages of the new unit soon became clear to us — in particular, the new programming and control system of the unit, as well as the 360° gluing.

And the option of being able to process zero joints?

Originally, that was only of secondary importance. It was an interesting option but it wasn't essential for us.

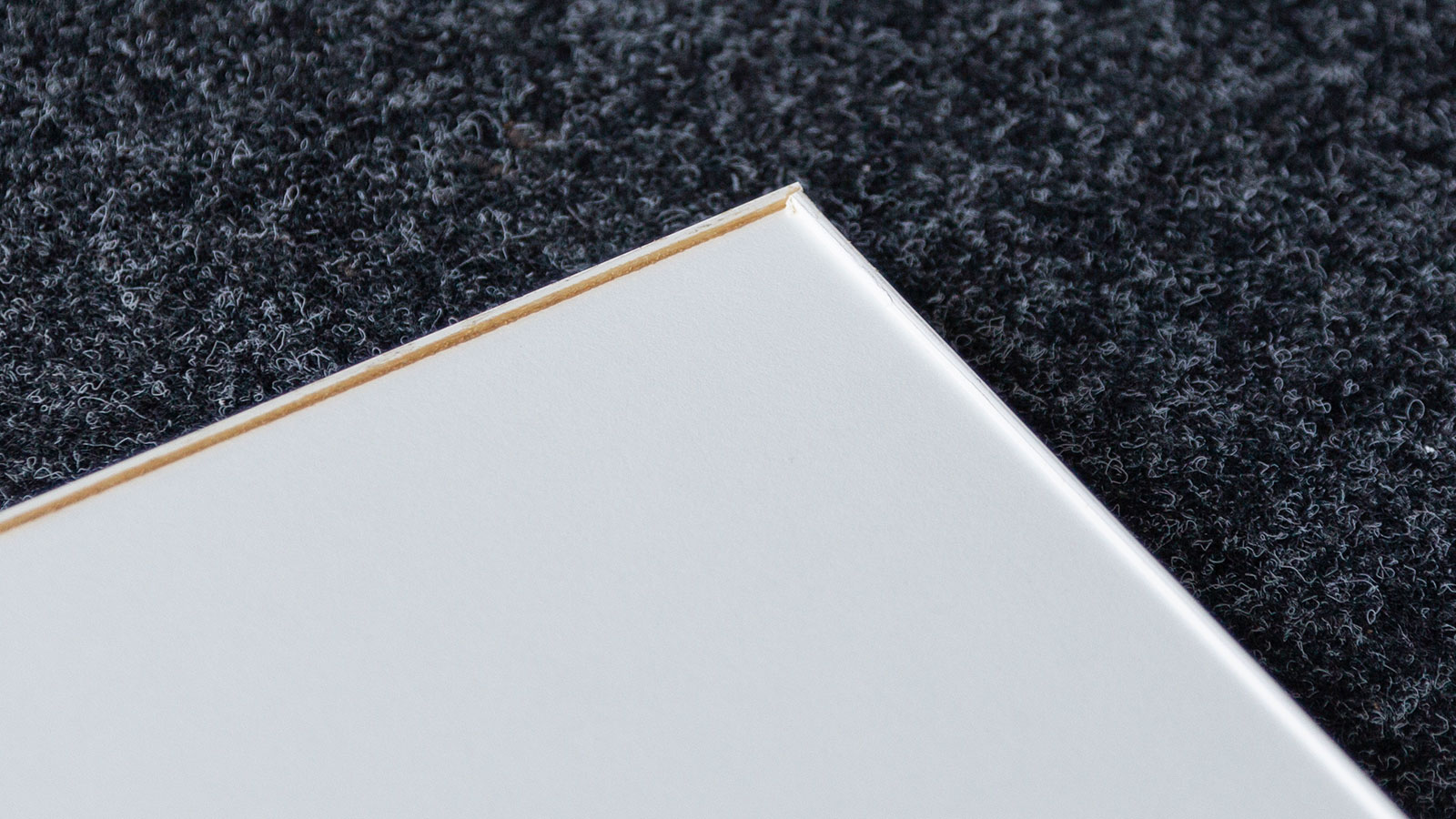

Now, however, we frequently use zero joints, especially due to the easy handling and the matching joint without a change in the glue color. Therefore, we also use the zero joint for parts with a straight edge when we are producing small quantities, for example, or for visually high-quality components such as with Arpa Fenix laminate.

You have been using the unit for several months. What conclusion have you come to?

We have been able to use the unit fully from the very beginning and it has proven its worth. It's very stable and the programming is also significantly easier. Programs can be run with higher feeds than ever allowing the operator to complete the required task more quickly. For us, the unit is a real step forward.

An article of the trade magazine BM 10 / 2019. Here you read the article on BM-Online.de

“The advantages of the new unit soon became clear to us.”Manfred Weid, Technical manager and authorized signatory, Ackermann GmbH

Ackermann GmbH

More than 120 employees rely on the latest production techniques:

- six large-size CNC processing centers

- one PU hot melt calander press

- two CO2 laser cutting machines

- one CNC cutting plotter