With a turnover in excess of £150 million, Willerby is the UK’s largest manufacturer of holiday homes, lodges and bespoke buildings for the leisure industry, a position it has built over more than 70 years. Established in 1946, the company occupies a 90-acre site in Hull and stakes its reputation on dedication to detail and creating a quality product.

“Our mantra in the business is SQP,” explains Mike Sharp, process manager at Willerby. He continues, “This is short for safety, quality and production. We are passionate about looking after our workforce and our customers. Consequently, we are always searching for ways to improve the safety of our employees in our facility whilst increasing the quality and speed of our production.”

Comprehensive selection procedure

“As you can imagine, over the years we’ve built up a tremendous knowledge and experience of many of the woodworking machinery companies out there and we know which the stars are and which to avoid.

“Despite this, we always approach a new investment from a clean sheet of paper. So, when it came to looking for some new beam saws to replace ageing models which were beyond economical repair, we carried out a thorough due diligence process.

“Our maintenance engineer, Sam Buckley, and I approached all the current saw manufacturers with a spec of what we wanted to see if they could satisfy our requirements. Later we met with most of the companies at the LIGNA show to discuss their machine solutions and following the show we drew up a short list.”

Fast, reliable woodworking machinery that delivers

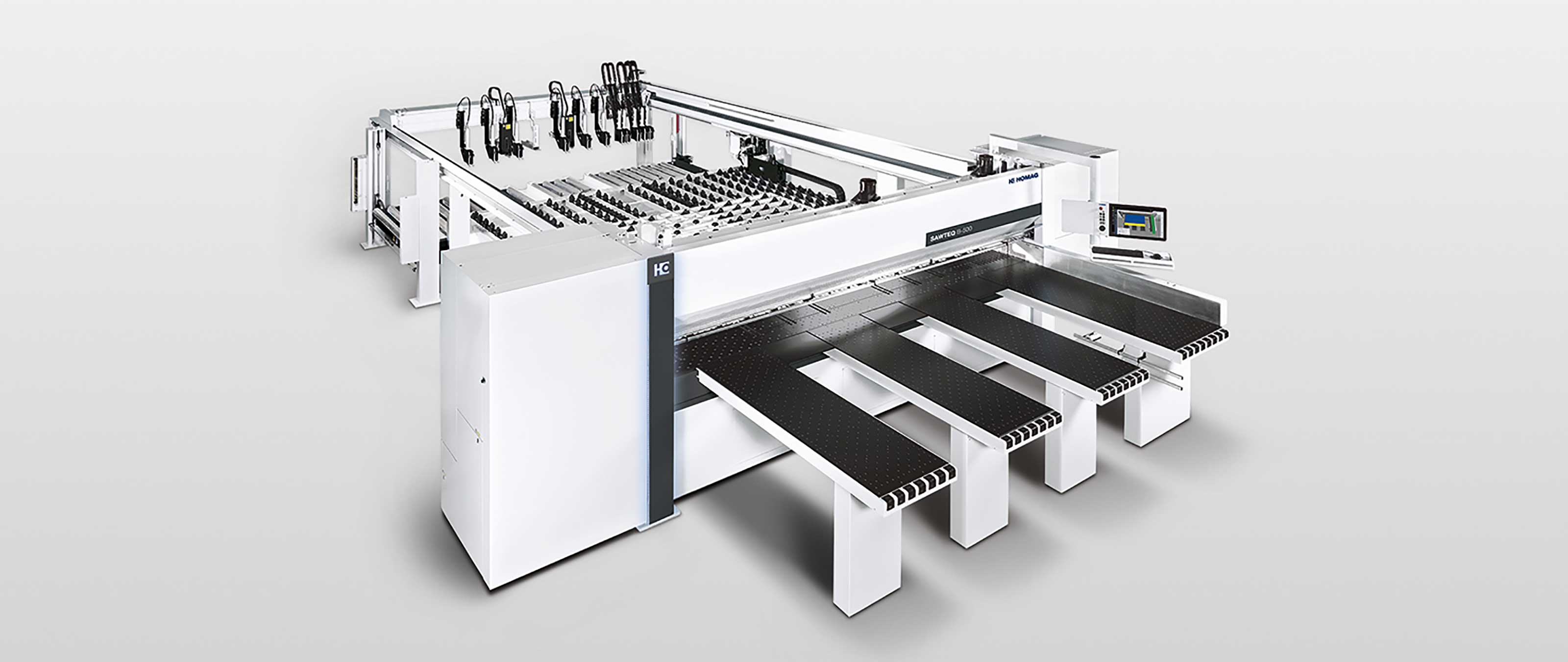

“At the end of the process, it was HOMAG that really impressed us. Not only could its beam saws meet our specification, but also John Shepherd, HOMAG’s area sales manager, was able to take us to a couple of UK installations to see both models of the saw – the HPP 400 and the HPL 500 – working in anger, so to speak, in real manufacturing environments.

“In addition to this, our previous experience of HOMAG, both machinery and service, gave us complete confidence that our significant investment would be in safe hands with them. On the shop floor level, our operators were also very keen to go the HOMAG route because of the positive experience they have of working on HOMAG machines over a period of more than thirty years.”

Getting the specification spot on

“From the outset, we worked closely with John Shepherd to create the exact specification we required for the saws. John’s knowledge and experience was a vital element in ensuring we got the best saws for the tasks we needed them to perform.

“As a consequence of John’s advice we specified a couple of optional extras on the HPL 500 saw which have proved to be invaluable. We’ve already achieved a 14 per cent increase in capacity with the new saw and there is more to come as we integrate it fully into our work flow.

“The first optional feature is a rotation device for head cuts. This is a real labour-saving device for our operators and has significantly increased output whilst improving health and safety for our people. They no longer have to perform the energy sapping manual turning of large panels; this work is all done automatically by the saw and ultimately this gives us improved productivity across the board.

“The other option that has helped speed up production dramatically is the Power Concept. This is effectively an additional clamp at the back of the saw that can be moved independently; it enables us to size several panels with different cross cuts lengths by cutting them all together in one pass. This reduces the number of saw operations we have to make and considerably increases our throughput speeds.”

Installation and training – smooth, quick and efficient

“The installation process was really impressive for the HPL 500. It’s a big machine and yet the HOMAG engineers working in conjunction with our own team were able to install and commission the machine in one week. I’ve certainly not experienced anything quite so professional before. Everything that was promised was delivered on time and we’re more than happy with the installation.

“The operators were trained on site by the HOMAG engineers and although CADmatic 5 was a brand new operating system for them, they were able to get to grips with it quickly. Combined with the MagiCut optimiser software we use it is a very powerful system.”

Lasting benefits that we can rely on day-in, day-out

“Our main key performance indicator (KPI) is safety and the HOMAG HPL 500 saw has really helped us improve the health and safety for our operators. They are no longer fatigued by having to turn big heavy boards; this ultimately means they are not only healthier, but also more productive throughout the day.

“The other two big KPIs for us, quality and reliability, have been delivered in spades with the HPL 500. On the quality front, our first production process is sizing of the large boards (2070 x 2800 mm); if we can get high quality cuts for this first process then we have the opportunity to maintain that quality throughout the remainder of the production process. Conversely, if we get a poor quality first process, then it is almost impossible for us to pull it back through subsequent processes.

“Reliability is vital for our production. The HPL 500 is so reliable we can plan production for the factory against it running perfectly every time we switch it on; we just don’t envisage any breakdowns or any problems with the saw at all.”

More to come from HOMAG

“Looking ahead, we’ve also got two HOMAG HPP 400 beam saws on order; these are due for installation by the end of January 2018 and we expect exactly the same levels of performance from these as the HPL 500 delivers. One of the HPP 400s will predominantly cut work tops and the other will focus on cutting plywood parts.

“Overall, it is the tremendous communication we have with HOMAG that makes the working relationship so strong. Whenever we speak to them we always get the answers we require; they keep us informed at all times, never leaving us in the dark.

“HOMAG always delivers on its promises. Everything it does is first class, from John Shepherd the area manager to the engineers that install and commission the saw onsite; from the team in Germany we met when we went over to sign off the machine in the factory to the visits of UK sites to see the saws in action. There wasn’t anything that HOMAG did that wasn’t short of excellent,” concludes Mike Sharp.

If you would like more information or a demonstration of the latest HOMAG saws or other machinery and software please contact HOMAG UK on 01332 856424.

“The installation process was really impressive for the HPL 500. It’s a big machine and yet the HOMAG engineers working in conjunction with our own team were able to install and commission the machine in one week. I’ve certainly not experienced anything quite so professional before. Everything that was promised was delivered on time and we’re more than happy with the installation.”Mike Sharp, Process Manager at Willerby