It is around the turn of the millennium, and Benjamin Löw and Thorsten Breidenbach are working in Ettlingen, Baden — Löw as an apprentice, Breidenbach a senior journeyman. The two keep joking: "One day we'll work for ourselves." Then Benjamin Löw goes to Australia for a year, studies timber construction and development in Rosenheim, completes his Master's degree eventually and returns to Baden as Plant Manager in 2009. But the office job is not for him — he wants to get back to the machine. So he calls his old companion to remind him of the promise made years ago in jest. Thorsten Breidenbach, who in the meantime has become a master craftsman, project manager and father, hesitates for a while before eventually agreeing.

In 2011, they become their own bosses. They hire a workshop, have the parts delivered and make their furniture. But their supplier cannot meet their quality requirements. Time to invest in their own Weeke CNC. There's no space for it, but Löw buys it anyway. The two master carpenters find a small hall, produce much more effectively thanks to the processing center and soon hire their first employee. This is followed by their first apprentice and their next move within Karlsruhe. But the edge bander, panel dividing saw and 5-axis CNC all need space, which soon becomes scarce again. In 2016, the young entrepreneurs found their current location, 20 kilometers south of Karlsruhe. All 15 employees moved with them. It was certainly not a guarantee that the employees would agree to move and it meant a lot to the owners.

Challenges are welcomed

Together with their team, Löw and Breidenbach are now just as much at home constructing stands for exhibitions as they are upscale furniture and interior fittings. They stand out from the market for several reasons: high flexibility, strong planning skills, a huge focus on technology and the courage to take on challenges. Nothing is off the rack here and the team really comes into its own when things get more demanding. For example, in projects where Corian is used.

This combination of mineral material and wood is not something most carpenters and customers see every day — but Benjamin Löw does. In a way, it is his passion. In addition to more classic pieces such as designer washbasins and reception desks for medical practices, the team also completes extraordinary projects. Recently, for example, it was an imposing kitchen counter with triangulated surfaces. Not only does it look stunning, it also causes many specialists to catch their breath when they think about the scale of the processing required. And there is certainly plenty of processing involved. But as we already mentioned: challenges are welcome in Elchesheim-Illingen.

With the right sawing macro from HOMAG staff member Kai Friebe, even surfaces like this no longer present an obstacle. Many colleagues from the region now come to Benjamin Löw when they are having trouble with CNC and 5-axis machining or have questions about processing Corian.

Buying a machine without having a hall for it, processing materials that would cause many to run in circles and taking on projects which can just as easily lead to strong growth or dramatic failure — all of this requires real courage and a willingness to take risks. This courage is what unites Benjamin Löw and Thorsten Breidenbach. But they do have their differences.

Different characters, one goal

Benjamin Löw likes to experiment — with materials, with programs, but also with machining processes. The joinery even has a laser for plastic processing, which is rather unusual for a wood-processing company. This is just one example of how this master carpenter pushes boundaries. And if he shoots wide of the goal, his partner is there to catch it. Thorsten Breidenbach is the so-called "voice of reason" in the company. But he also has another passion: baths. He brings decades of experience and a level of expertise in digital visualization and digital dimensioning.

As well as supplying the washbasins and bathroom cupboards, Löw Breidenbach also coordinates the trades. This is a route that the two would like to continue on with their team. This is also why they have now added an architect to their team. In this way, the Baden-based company would like to increasingly take on projects involving multiple trades, thus assuming responsibility for the overall planning and offering its customers complete room concepts. But this is more than just a dream for the future. A pilot project has already been successfully realized — a dental technology laboratory in 2018. In addition to construction management and supervision, the team was also responsible for dry-walling, electronics, lighting and sanitation. They are now ready to take on more orders, as well as looking for a suitable exhibition space and new offices. HOMAG machines will also play a role in these big plans.

Staying out in front with technology

To be able to grow sustainably and meet challenges, both founders quickly realized that they needed the right technology. They rely on HOMAG for this. Not just in terms of machine technology, but also for digital solutions. Here too, Benjamin Löw wants to explore new paths to avoid standing still. This is why the joinery frequently tests the digital HOMAG prototypes and thereby assists further development of the digital product range — as in the case of edgeband management, for example.

Löw Breidenbach want to remain at the cutting edge into the future — and they certainly have the courage to do so.

“The machines are running, the spare parts come on time and the service is good. We are definitely satisfied.”Benjamin Löw, Master Joiner and Owner

More about Löw Breidenbach Joinery

Products: Furniture construction, trade fair construction, interior fitting

Location: Elchesheim-Illingen, Germany

Founded: 2011

Employees: 15

First HOMAG installed: 2012

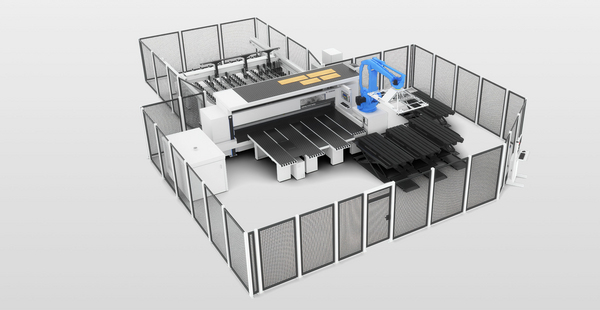

HOMAG machines used:

- KAL 375 edge banding machine (today: EDGETEQ S-500)

- Two BOF 210 CNC processing centers

- SAWTEQ B-400 panel dividing saw

- SANDTEQ W-100 wide-belt sanding machine