The company Wiemer Einrichtungen, which has 40 employees, lies between the rivers Rhine and Ruhr in Oberhausen, Germany. The company specializes in providing fittings for drugstores, equipment for medical practices and commercial fittings. Wiemer Einrichtungen, which is located in North-Rhine Westphalia, supplies an entire range of equipment — from office chairs and store equipment, to electrical installations. With 30 years of experience in store design, Wiemer has made a name for itself as one of the largest German manufacturers for drugstores.

The company's premises, which are situated close to the Emscher Canal and the Rhine-Herne Canal, appear very inconspicuous at first glance. However, when you enter the building, you find yourself in an enormous drugstore filled with sales counters, shelves of medication, cash registers and lighting. And there is a wide variety of unique designs. Wiemer's showroom consists of two floors over an area of 300 m². Here, creative ideas and solutions for drugstore designs are presented.

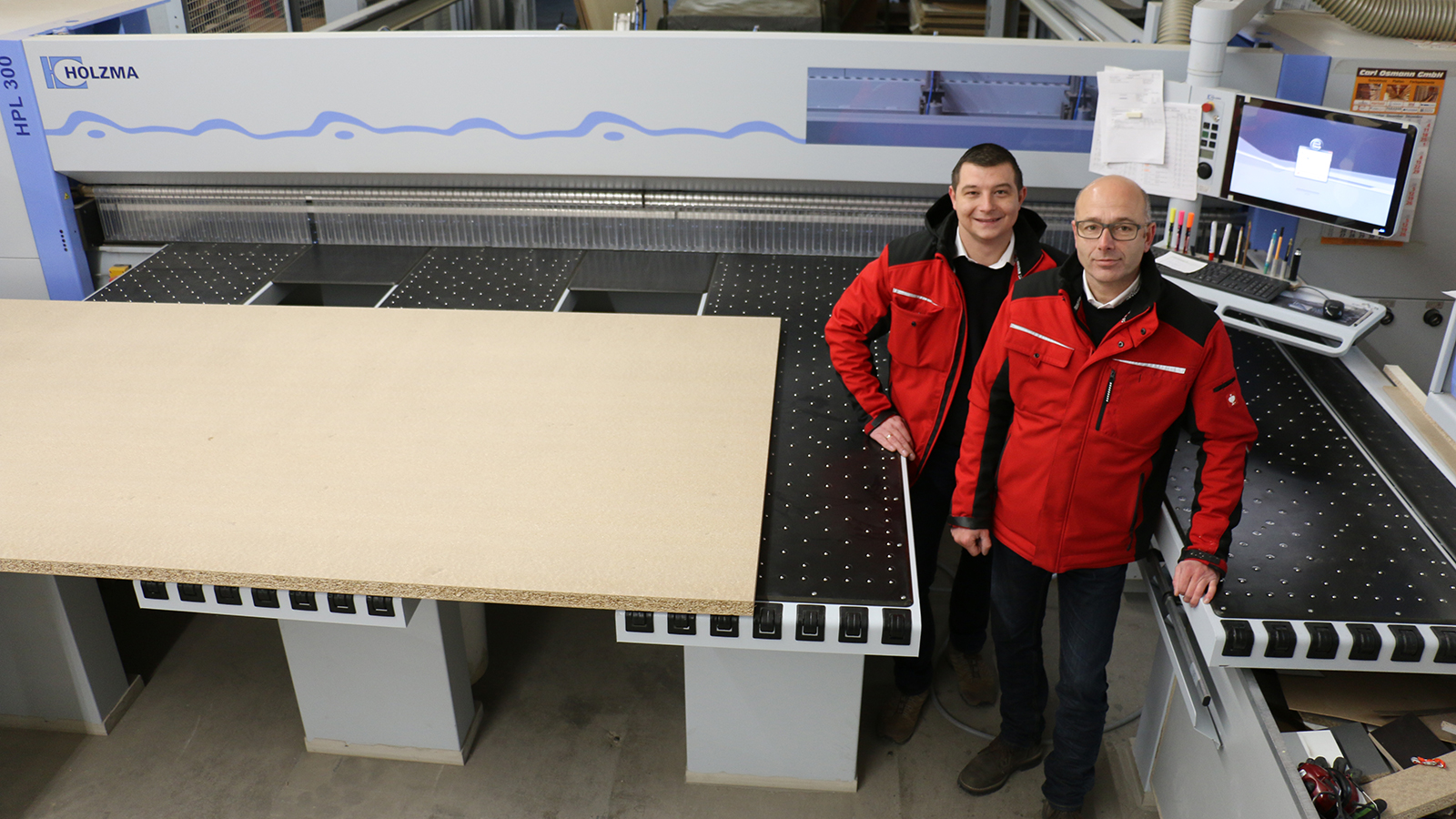

The two owners, Olaf Wiemer and Sebastian Rettig, proudly present the extensive services which their company provides: "We supply everything from start to finish and beyond," says Sebastian Rettig. By that, he means all the phases of creating a drugstore: from the first visit to the construction site, through to project management, material selection, production of the fittings, conversion of the building where necessary, and the final on-site assembly of the produced furniture.

"Fittings for drugstores have changed a lot in recent years. They have moved away from classic drawer solutions to fully automated storage facilities for goods," reports Rettig. Wiemer Einrichtungen is capitalizing on precisely this trend and is enabling customized solutions that are adapted to the circumstances at the specific site.

The order is processed and the project is planned in the company's own architecture office. "With the two-dimensional and three-dimensional visualization of the interior fittings, we want to give our customers the best possible basis for their decision," says Wiemer. Together with the original surface textures for walls, the floors, the light architecture and the designed furniture, the customer gets an exact image of the future drugstore.

In order to organize an entire store design under one roof, the company relies on important partner companies. Managed by Wiemer, the individual trades interact perfectly: electrical, sanitary and heating installation, masonry work, floor laying and decorating work, studwork and locksmiths.

State-of-the-art production

The employees in the furniture production, which is spread over 1600 m², are fully dedicated to the customer's wishes.

"The first machine we had was a panel dividing saw from HOLZMA. We were so impressed that we switched over to HOMAG completely," says Olaf Wiemer. Since then, the entire machine pool has consisted exclusively of HOMAG machines. "The fact that all of our machines come from HOMAG has two major advantages: The operation and the control system are the same for all the machines and the software programs are compatible."

Around five years ago, Wiemer acquired the panel dividing saw SAWTEQ B-300 (formerly: HPL 300), equipped with a lifting table and automatic feed, which allowed the company to significantly increase the number of sawn panels.

In order to process the variety of panel materials on an even more customer-specific basis, Wiemer decided to invest in a new edgebanding machine EDGETEQ S-380 (formerly: KDF 860) edge banding machine two years ago. Being able to continue to use a wide variety decors is important to Wiemer, so replacing the glue has to be easy. Thanks to two quick-change gluing stations and an additional preheating station, several different glue colors are used every day — the glues can be switched between PUR and EVA too.

When the new edge banding machine was purchased, the entire production was reorganized. This enabled shorter travel distances for materials, optimized processes, and increased efficiency.

One thing soon became clear: "Our existing CNC machine was simply too slow back then and always created a bottleneck in production," explains Rettig. "To bridge the delivery time for our new CENTATEQ P-310 (formerly: BMG 310), we also decided to buy a DRILLTEQ V-200 (formerly: BHX 055), which can drill, trim, and create grooves. This allows us to ease the load on our CNC machine and guarantee our customers even faster delivery times."

Since the company acquired the 33rd CENTATEQ P-310 to be built by HOMAG, production at Wiemer has been even more flexible. Large workpieces can be trimmed, drilled and grooved — even free-formed workpieces. The integrated CAM plug-in means that 3D parts and diagonals can be easily programmed and implemented directly on the machine. "With the CNC from HOMAG, we can manufacture furniture for our customers with a greater level of customization — we have more technology, but still don't lose our love for the craft," explains Wiemer. The machine control unit with LED system also allows fast and safe positioning for consoles and clamping elements.

To ensure that the company can always offer customers the most up-to-date production solutions, Wiemer replaces the machine pool every six years. In order to provide optimal advice about replacing the machine pool, HOMAG works in close cooperation with the sales partner Maschinen Kaul in Düsseldorf. "We have been looking after Wiemer for over six years. This has given rise to a trusting and friendly relationship, which is very important to me," says Marc Flöth, customer advisor at Maschinen Kaul. As the intermediary between HOMAG and Wiemer, Kaul conducts the training for machine operation, provides support with maintenance, and is the contact partner for after-sales.

Customer satisfaction beats storage costs

In all projects, customer satisfaction is the top priority for Wiemer. For example, decors used are held in stock for up to 10 years. This means that repair work—for example, due to water damage—can be implemented quickly on existing drugstores.

In addition to the quality of the work performed, delivery reliability and punctuality are also important. Because the conversion of a drugstore generally involves a transition solution, it is even more important to adhere to agreed schedules. "The conversion of a drugstore should take a maximum of four weeks," says Olaf Wiemer. "To make the transition time as bearable as possible for the pharmacist, we offer a mobile drugstore." Each container drugstore can be adapted to meet requirements for size and fittings, from a sales room to a fully equipped laboratory.

Sales often increase in the transition phase, because curiosity takes the upper hand. "Customers want to see how the conversion is progressing and the mobile drugstore itself repeatedly draws customers in," adds Sebastian Rettig. "The customers are happy to accept a certain level of improvisation."

“The fact that all of our machines come from HOMAG has two major advantages: The operation and the control system are the same for all the machines and the software programs are compatible.”Olaf Wiemer, Owner of Wiemer Einrichtungen GmbH

More about Wiemer Einrichtungen GmbH

The company Wiemer Einrichtungen, which has 40 employees, lies between the rivers Rhine and Ruhr in Oberhausen, Germany. The company specializes in providing fittings for drugstores, equipment for medical practices and commercial fittings. With 30 years of experience in store design, Wiemer has made a name for itself as one of the largest German manufacturers for drugstores.

wiemer-einrichtungen.de