Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Work Preparation woodWOP

Work Preparation woodWOP

Easy programming of workpieces in 3D

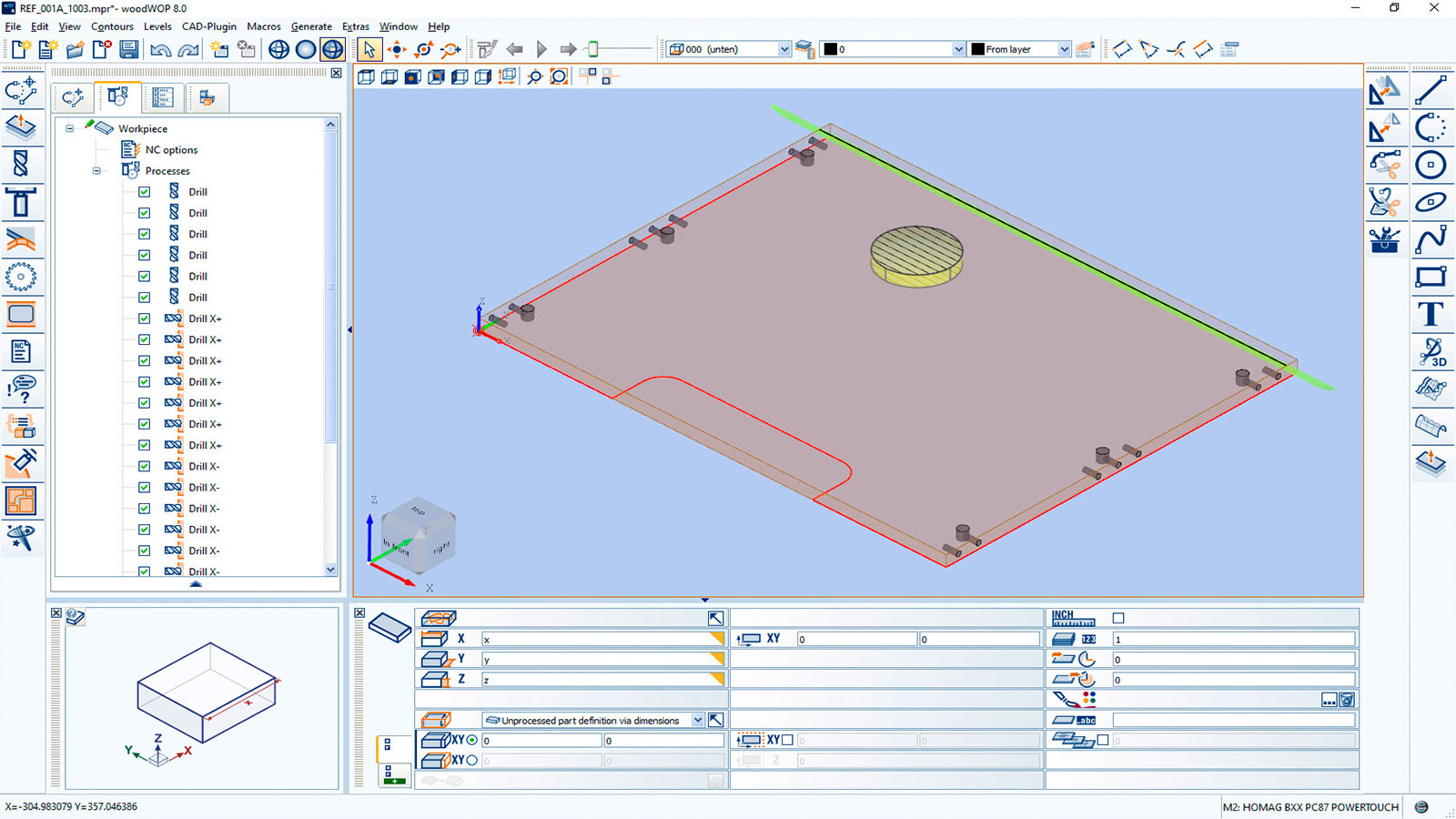

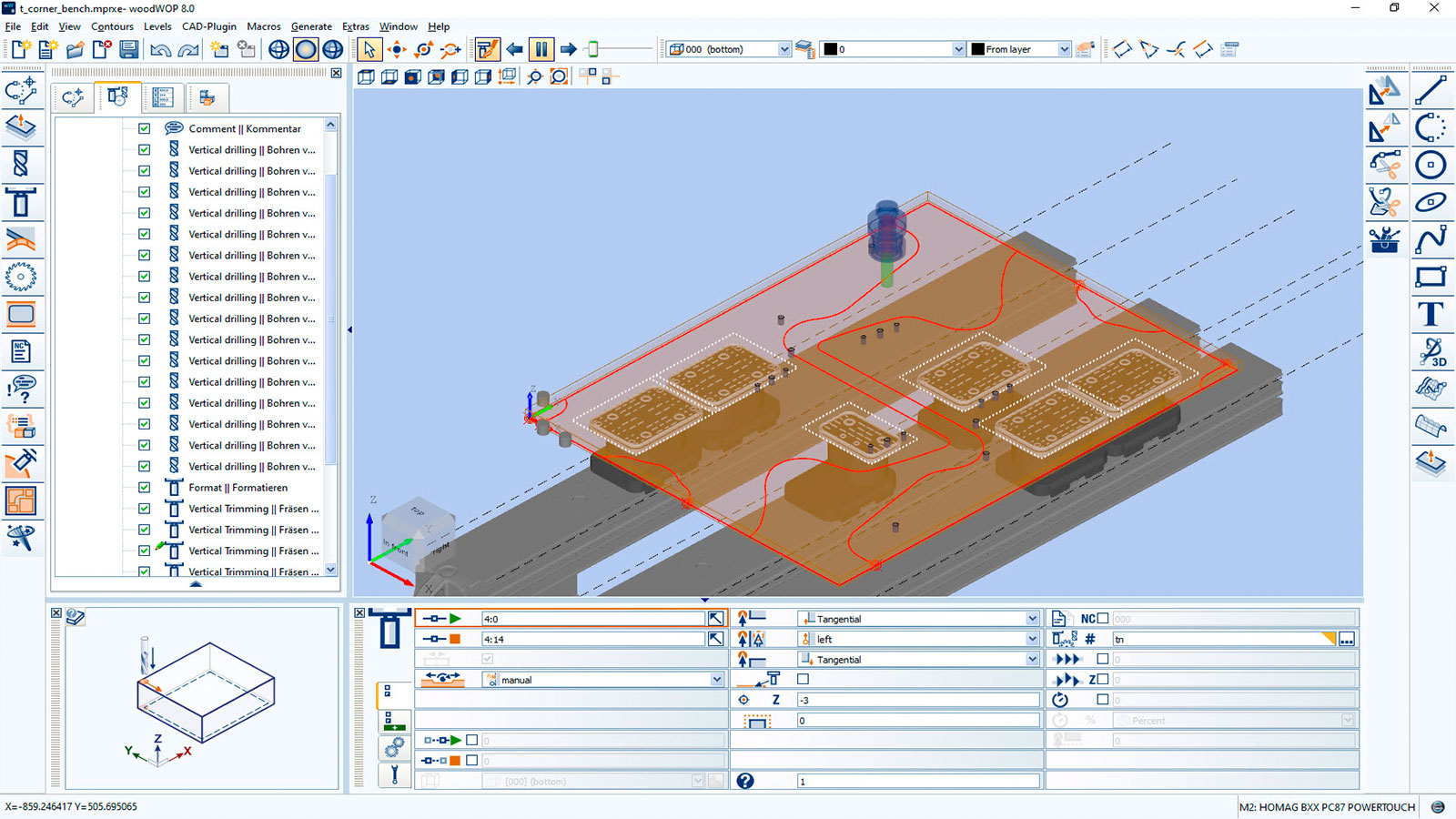

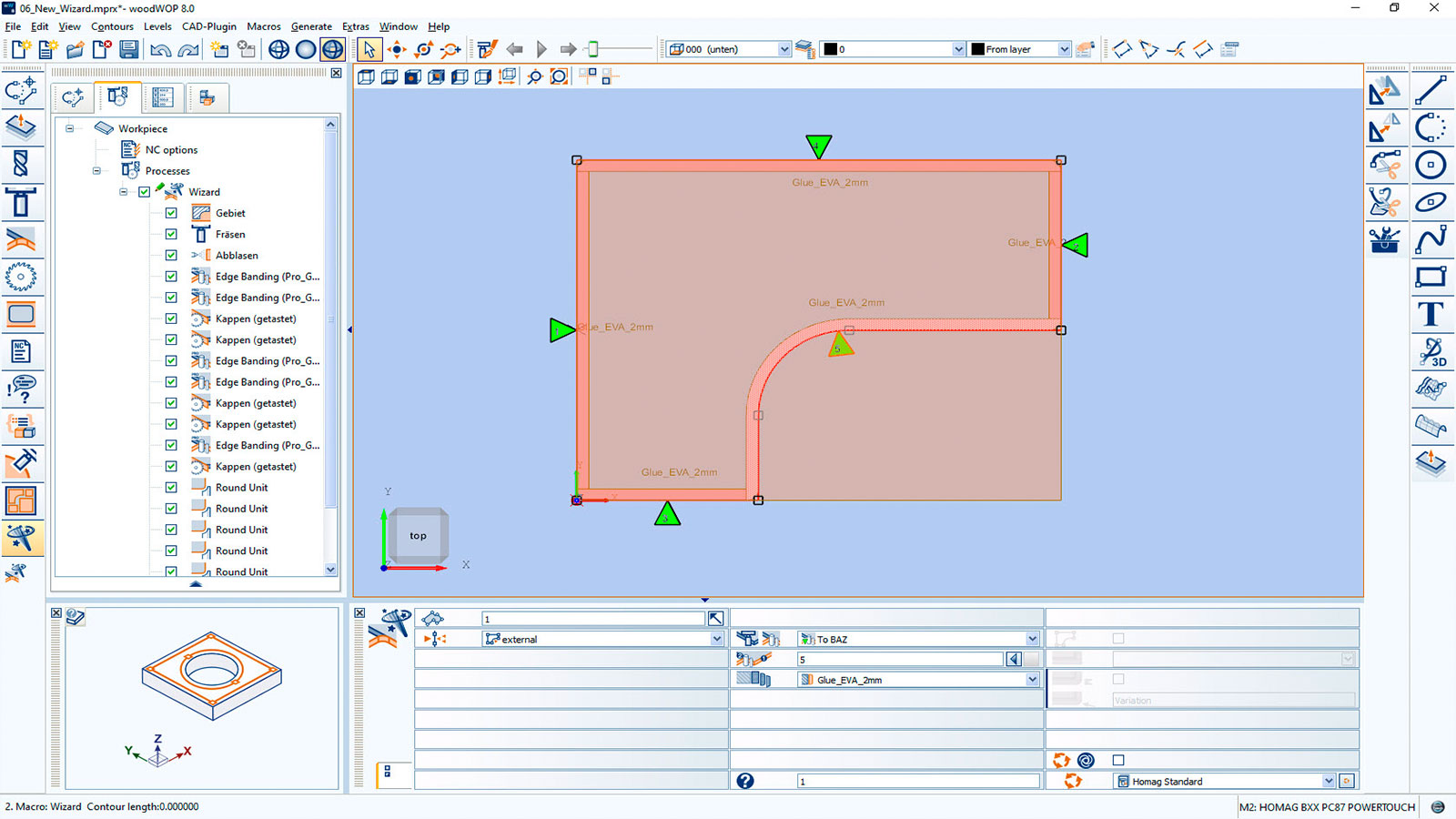

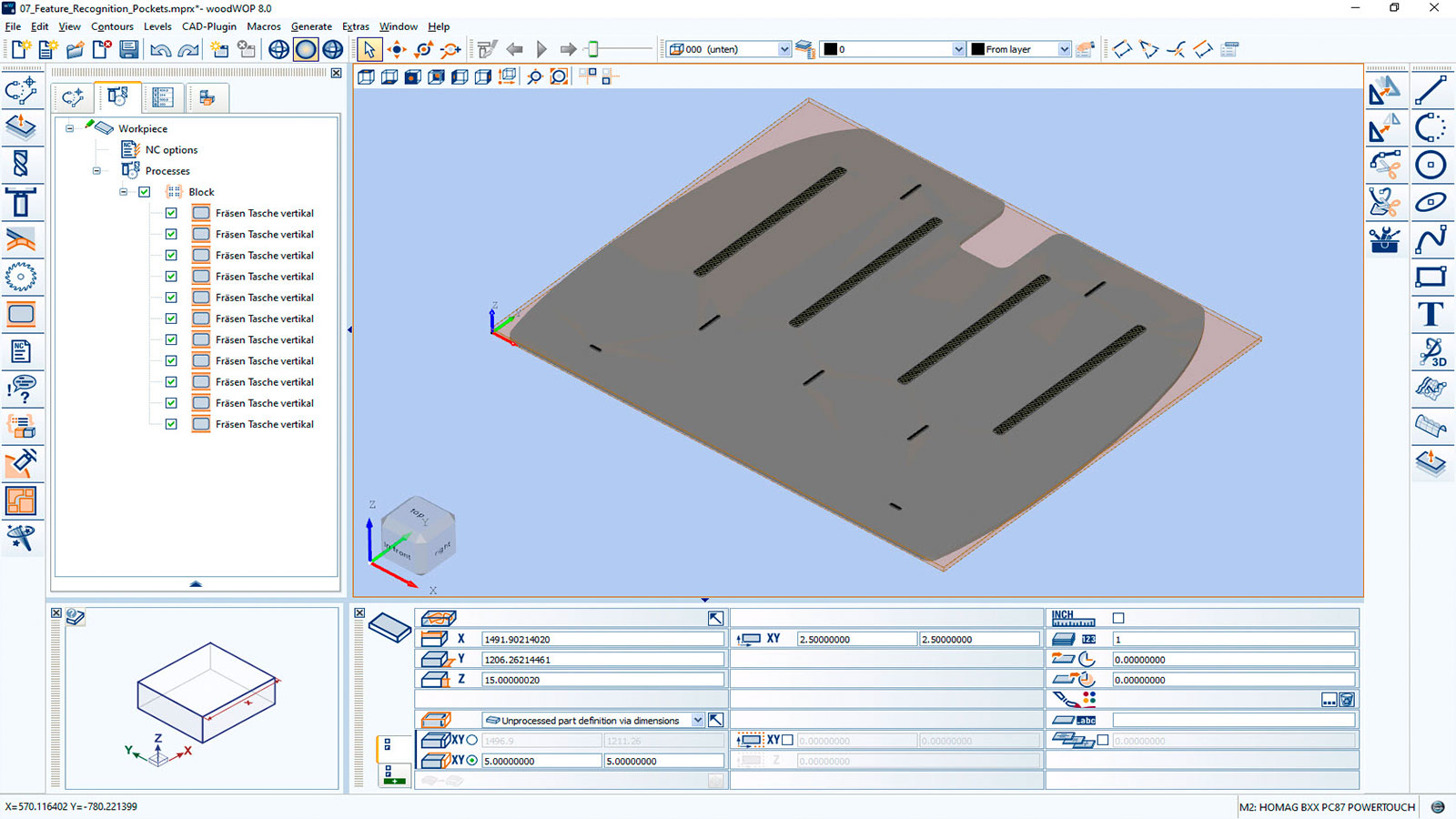

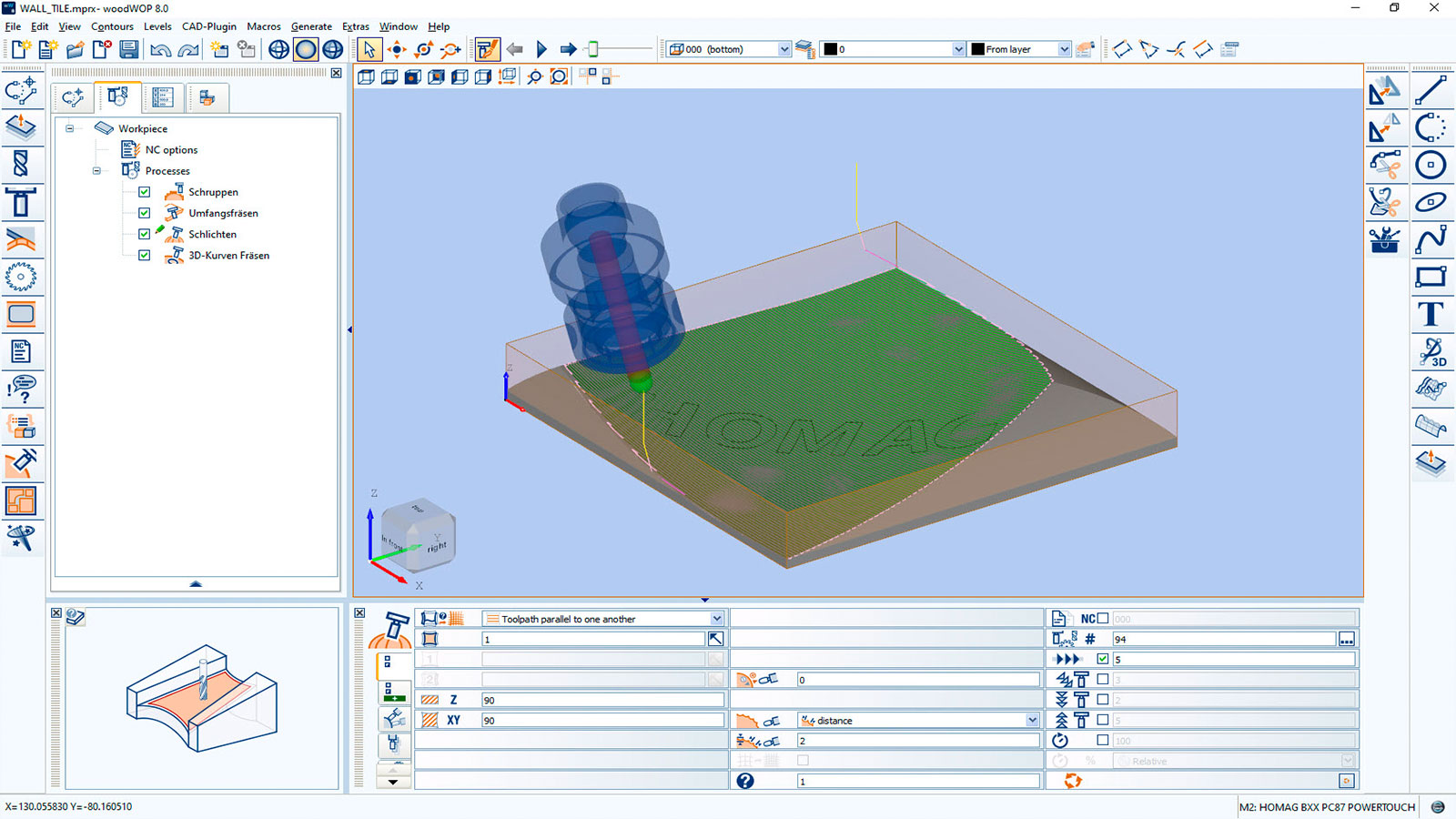

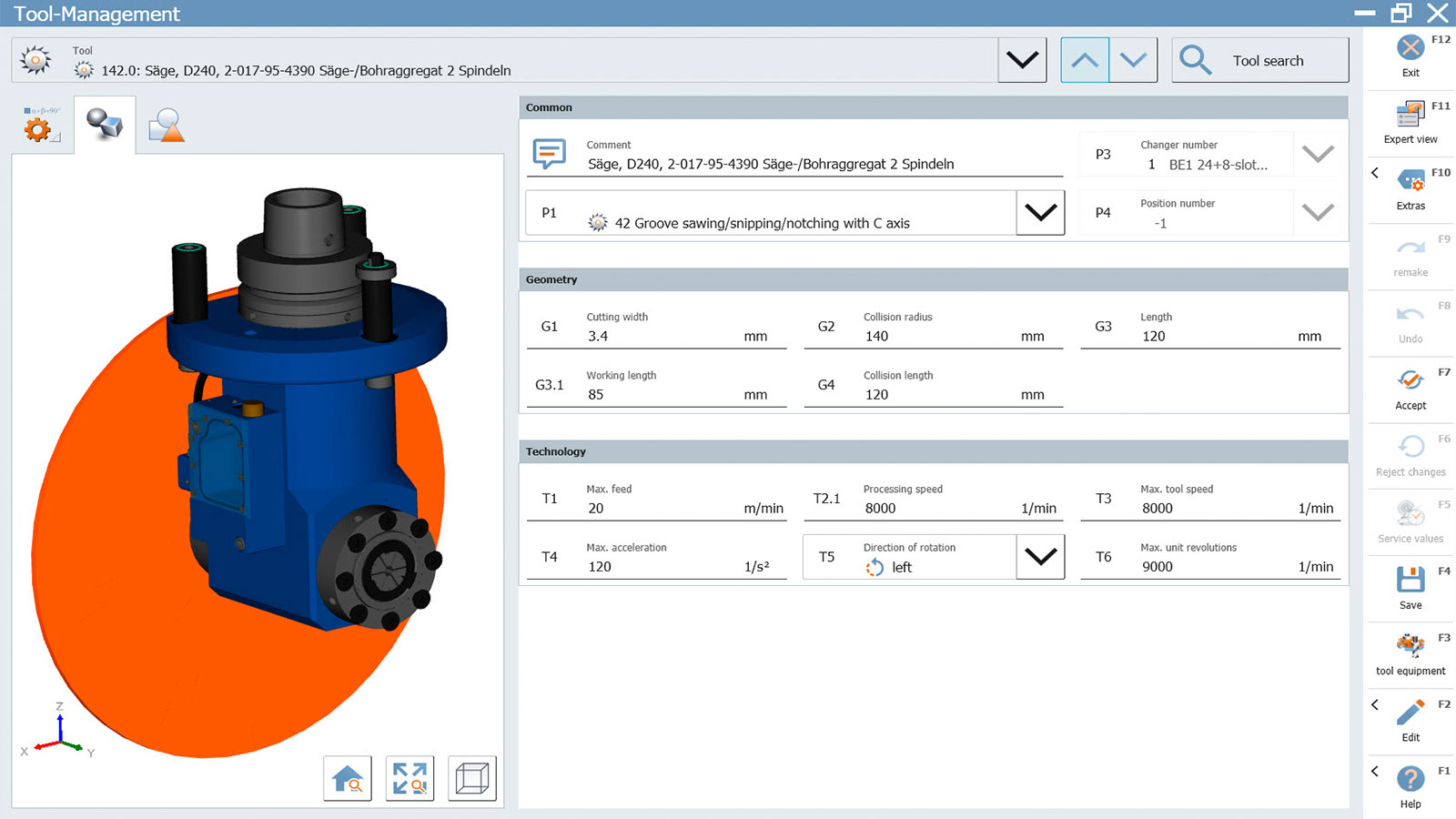

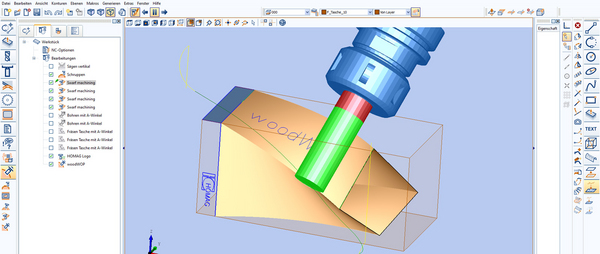

The woodWOP interface is centered around the large graphics area. The workpiece, processing steps and clamping equipment are displayed in 3D. Trimming, bore holes and saw cuts can be programmed quickly and easily by entering the processing parameters, and can then be checked immediately in the graphics area. This optimizes programming reliability and enables you to constantly monitor the creation of the program.

Images

Features

-

Numerous standard processing steps, such as bore holes, saw cuts and pocket trimming, ensure that it is easy to get the program started

-

Easily save your own processing steps and insert at the click of a mouse using components

-

Global online forum for CNC programming: https://forum.homag.com

Share your ideas with colleagues! -

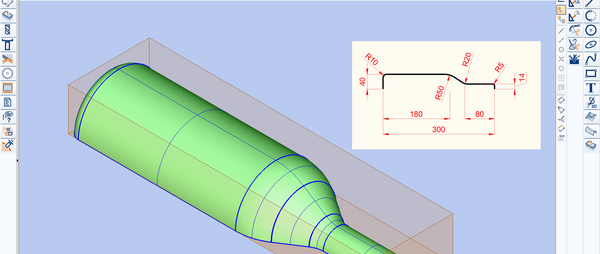

Automatically generate milling paths from 3-axis processing right through to interpolating 5-axis processing with the CAM plugin (optional)

-

Design 3D surfaces and import 3D models from external CAD systems with the CAD plugin (optional)

-

Work preparation is optimized thanks to a simulation of the processing steps with material removal, collision detection and time calculation with woodMotion (optional)

Start now!

Further Solutions

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

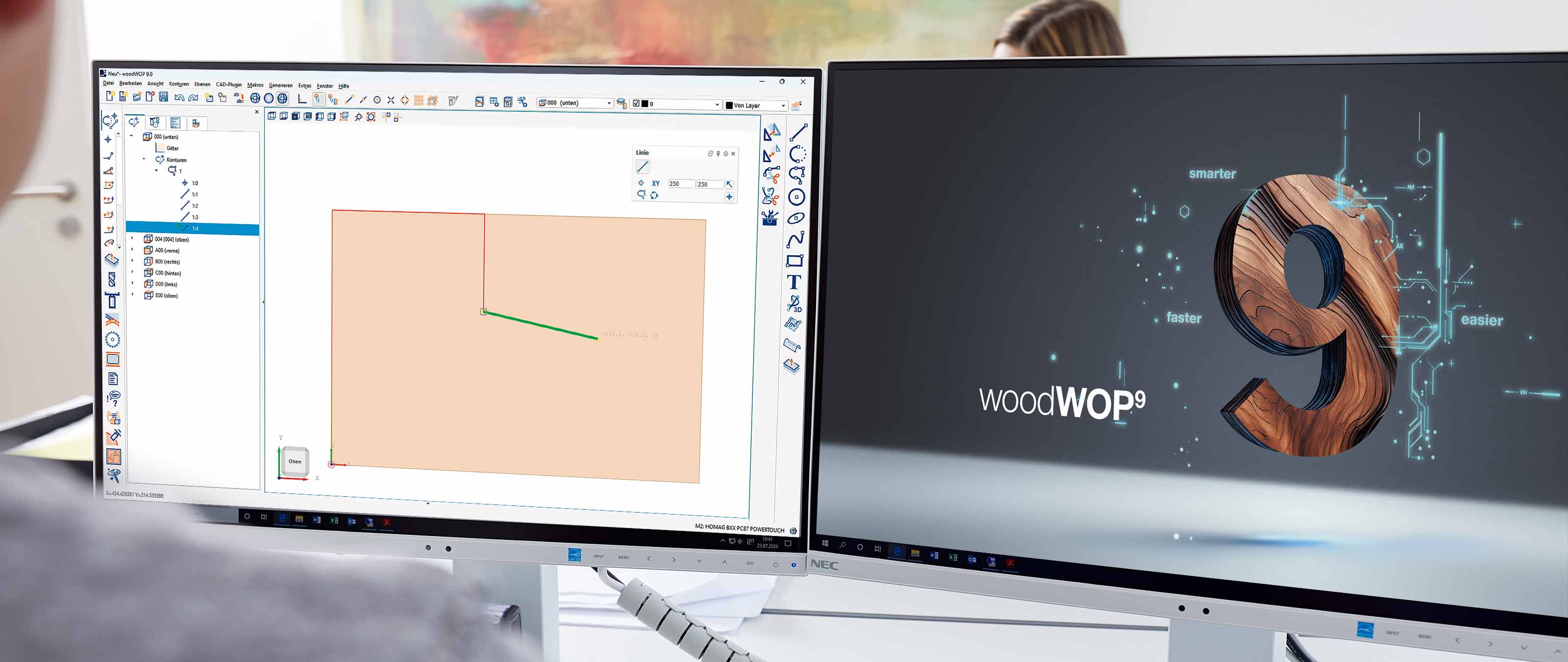

woodWOP 9 CNC programming Software

Focused on focus. | The highlights at a glance: The new version comes with an optimized user interface: clear lines, a uniform colour scheme. The focus is entirely on the workpiece.

Brochures