CNC Drilling and Routing Machining Centers DRILLTEQ V-200

CNC Drilling and Routing Machining Centers DRILLTEQ V-200

A flexible all-rounder for processing in just 5 m²

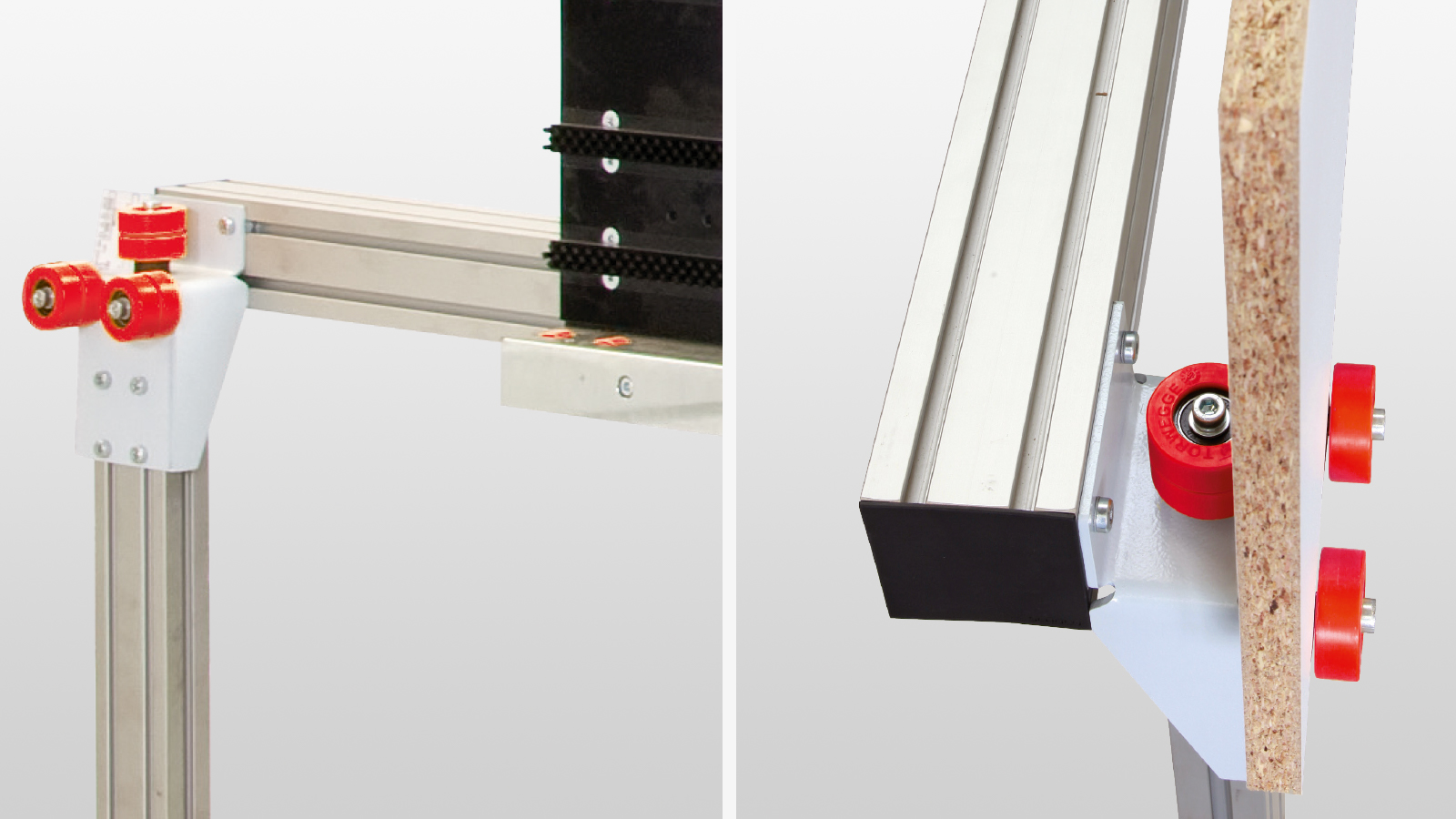

These versatile machines can be used for drilling, trimming and grooving, offering the ideal solution to save you time, space, energy and money. They are particularly well-suited to just-in-time production for trade businesses and other small businesses, and for custom production in large companies.

Highlights

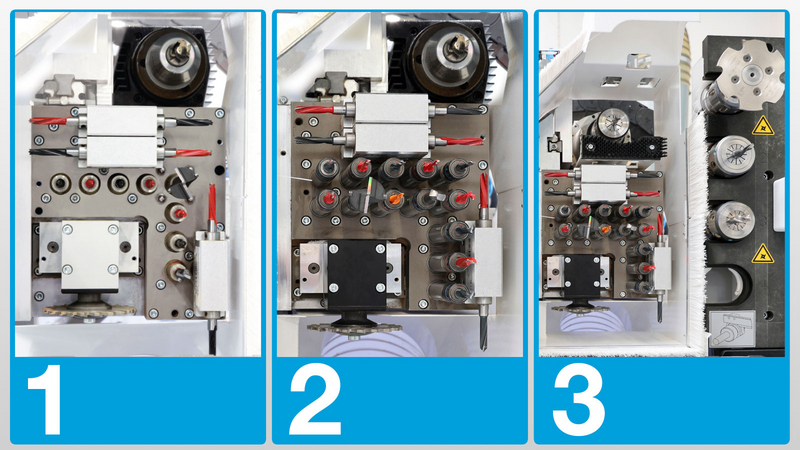

There are 3 configurations to choose from.

Package 1:

8 vertical drilling spindles | 4 horizontal in X-direction | 2 horizontal in Y-direction | grooving saw

Package 2:

13 vertical high-speed drilling spindles | 4 horizontal in X-direction | 2 horizontal in Y-direction | grooving saw

Package 3:

13 vertical drilling spindles | 4 horizontal in X-direction | 2 horizontal in Y-direction | grooving saw

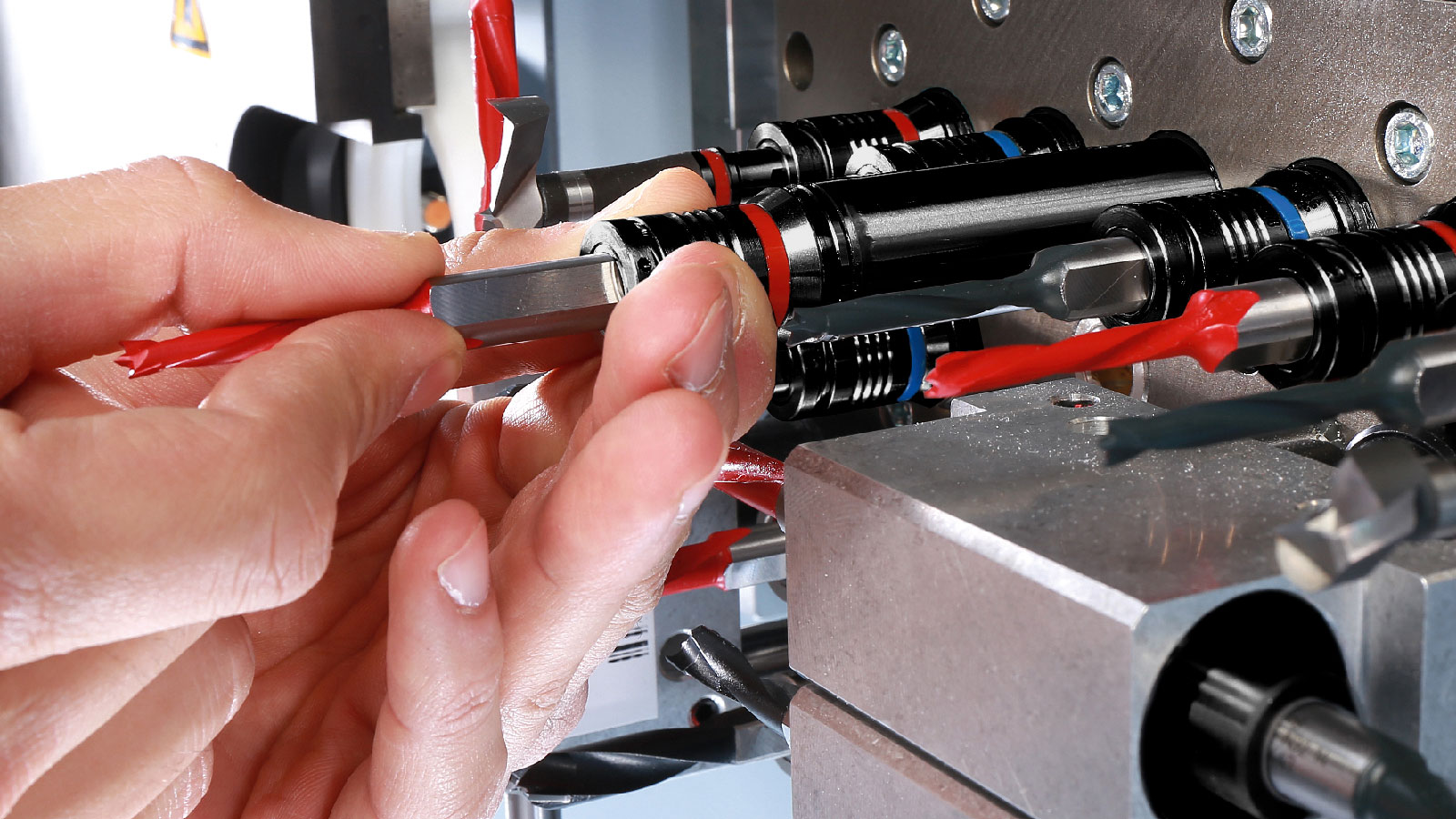

Workpiece clamp: Energy-efficient processing - The collet chuck system convinces without set-up times and vacuum

Images

Features

-

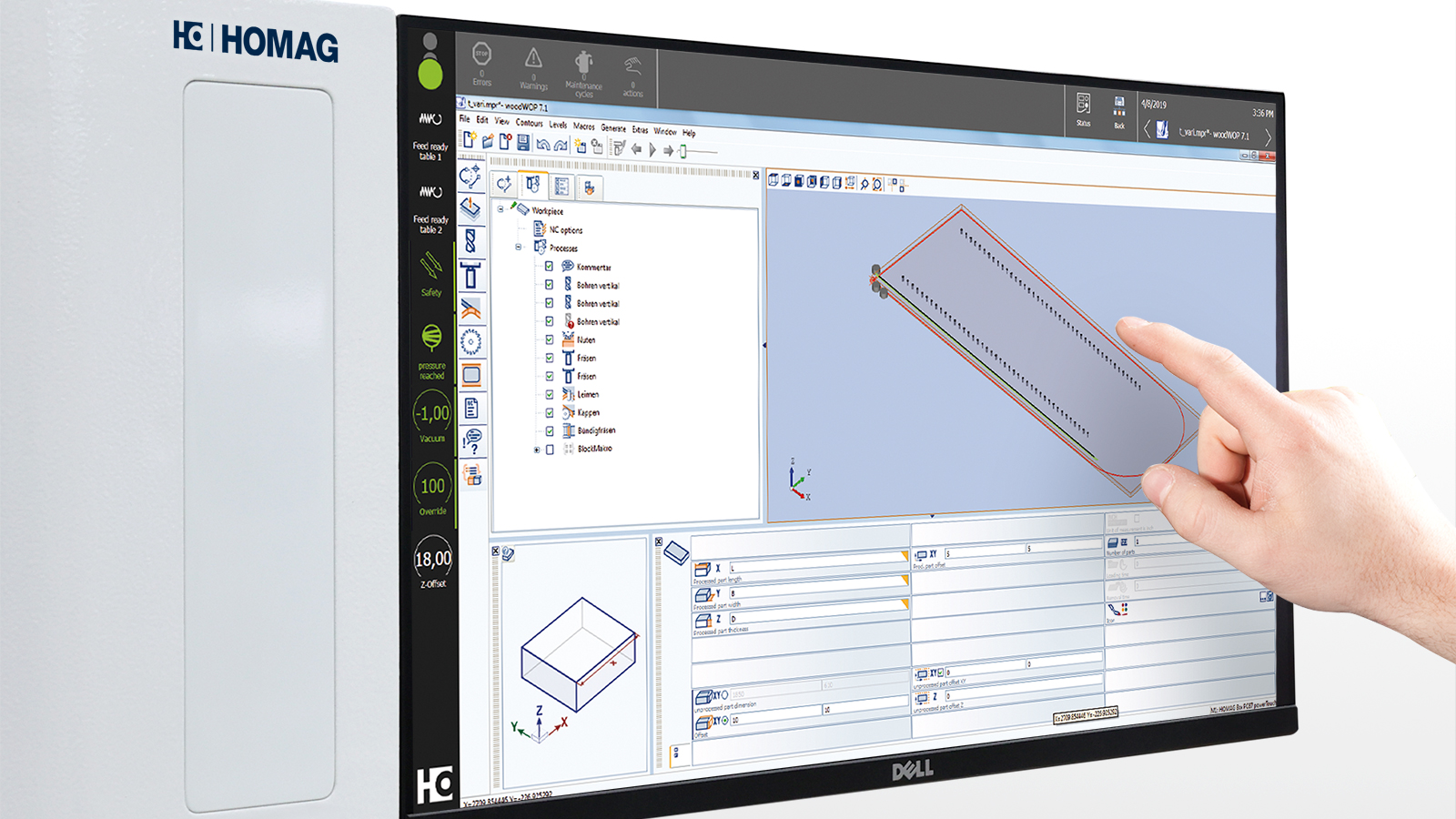

Plausibility check:

Check of the actually inserted workpiece using sensor technology in the X and Y directions. Comparison with the values in the database. If the defined tolerance value is exceeded, the current process stops. At the same time, the operator receives a a message to correct the workpiece. This keeps you on the safe side -

Length-dependent processing in the X-direction:

The workpiece is measured exactly in length in the X direction by a measuring run after processing release. Dimension-dependent holes are then automatically corrected by any tolerances determined. You save time and gain quality. -

Extraction hood:

Increased extraction capacity in the area of the milling unit for larger cutting cross-sections, optionally selectable. -

Application examples:

Whether classic milling and drilling or the production of pockets. There are no limits to the choice of furniture connectors.

e.g. continuous back panel groove, flat drilling operations for eccentric connecting fittings, classic dowel holes or Clamex P connectors. -

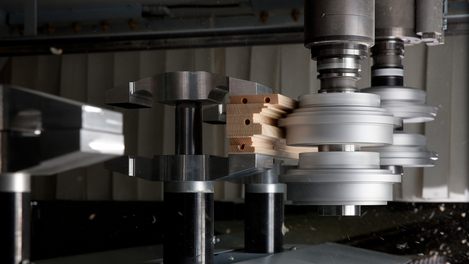

Automatic tool change magazine:

Up to 4 tool positions for flexible production.

Start now!

Technical Data

| DRILLTEQ V-200 | |

|---|---|

| Workpiece length [mm] | 200 – 2,500 (optionally 3,050) |

| Workpiece width [mm] | 70 – 850 |

| Workpiece thickness [mm] | 12 – 60 |

| Total machine weight [kg] | ca. 1,580 |

Technical information is subject to change.

(Previous product name: Vertical CNC processing centers BHX 050/055)

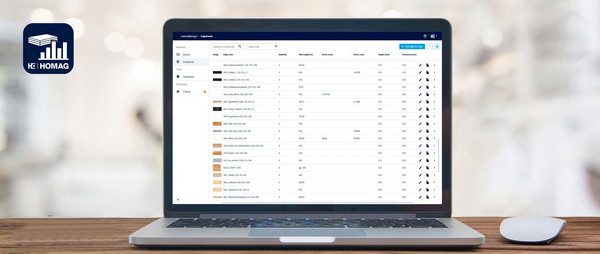

Software

Here's how your colleagues produce

You might also like

Videos

Vertical CNC Processing Center DRILLTEQ V-200 | Trailer

The smart all-rounders for drilling, routing, grooving!

Brochures