Panel dividing saws SAWTEQ A-500 | A-510 Winkelanlage

Panel dividing saws SAWTEQ A-500 | A-510 Winkelanlage

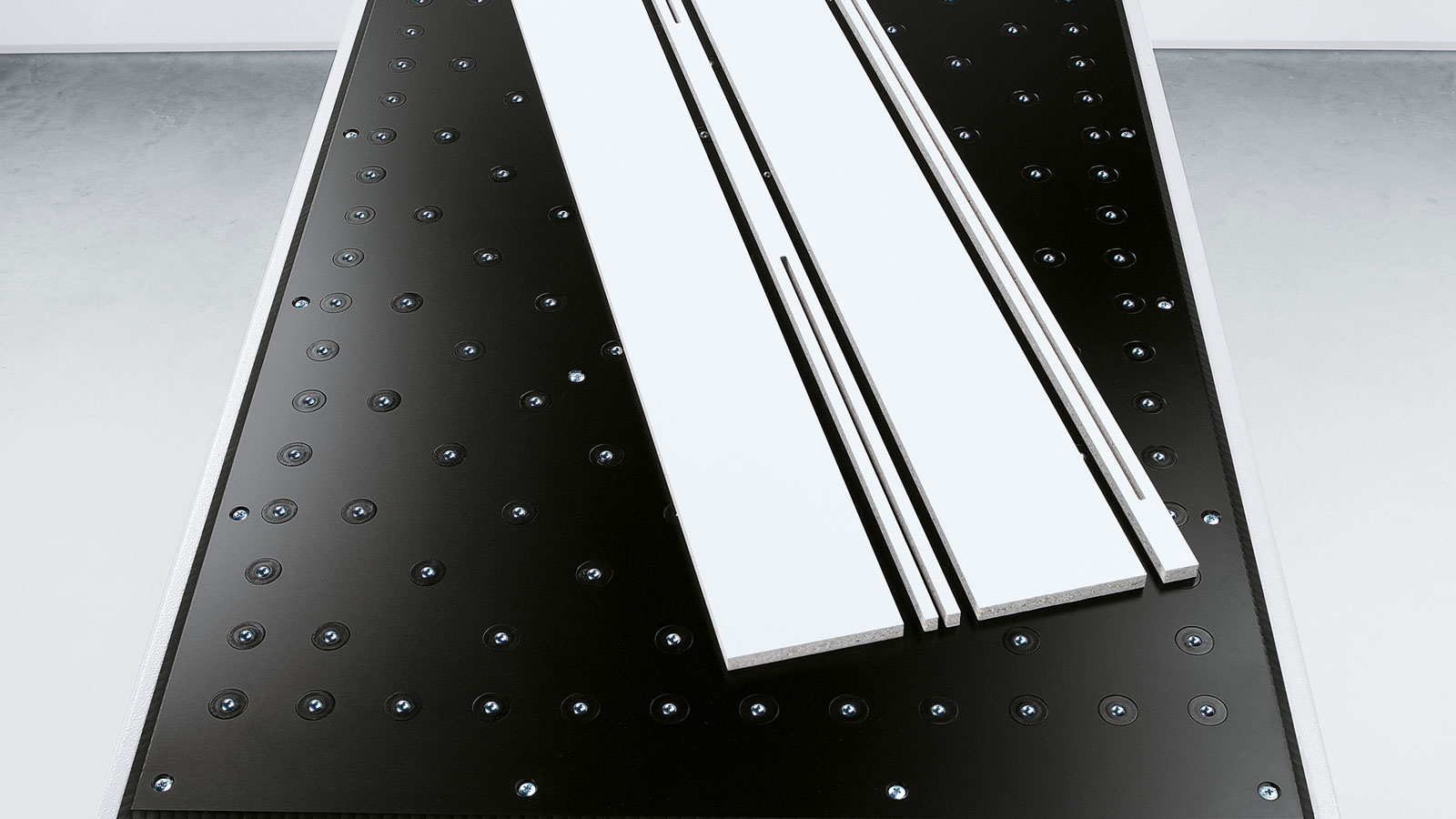

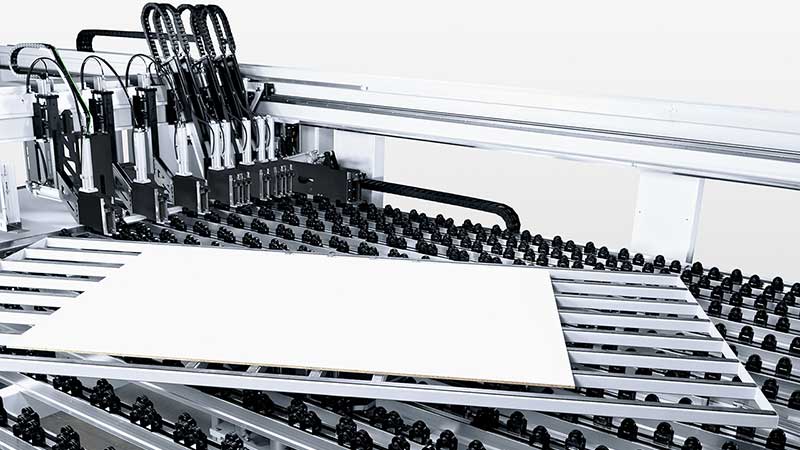

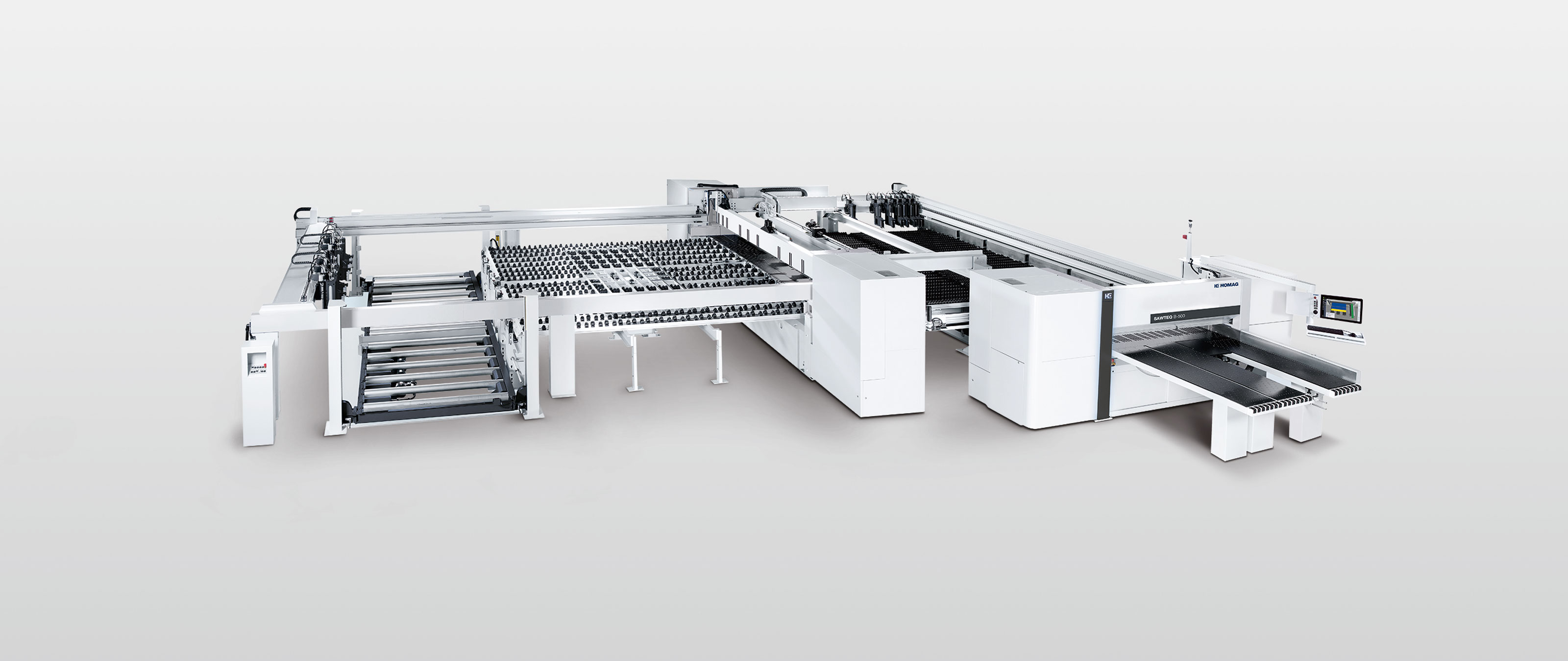

Plenty of output in a short time: the fully automated angular saw unit of the 5 series sets the benchmark in industrial manufacturing and is particularly powerful.

The SAWTEQ A-500 | A-510 was designed for continuous industrial use. As an angular saw unit it scores high in cutting thanks to the technological advantages of the 5 series, its size and power, and its flexibility in terms of configuration. This high-tech saw is ideal for multi-shift production environments and for integration in industrial production lines.

Benefits

Images

Features

-

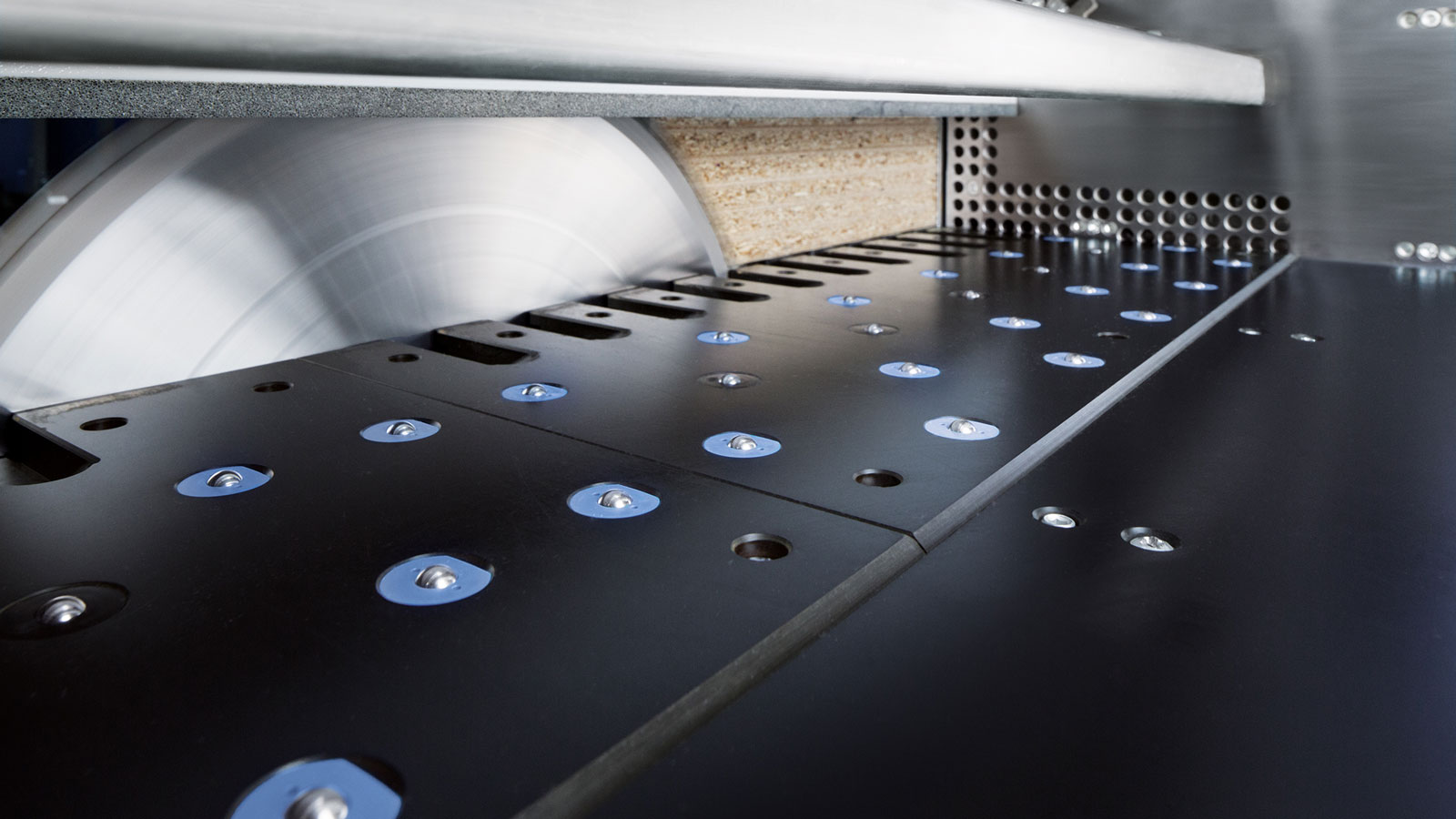

Rugged, torsion-resistant saw carriage with infinitely adjustable feed speed for maximum dynamics and precision

-

Saw body made of SORB TECH – advantages over steel girder designs:

– 10 times better vibration dampening

– 20% higher sound absorption

– 30% longer saw blade life

– 40% lower consumption of primary energy during its production -

Main saw raised pneumatically, for higher positioning speed and easier maintenance

-

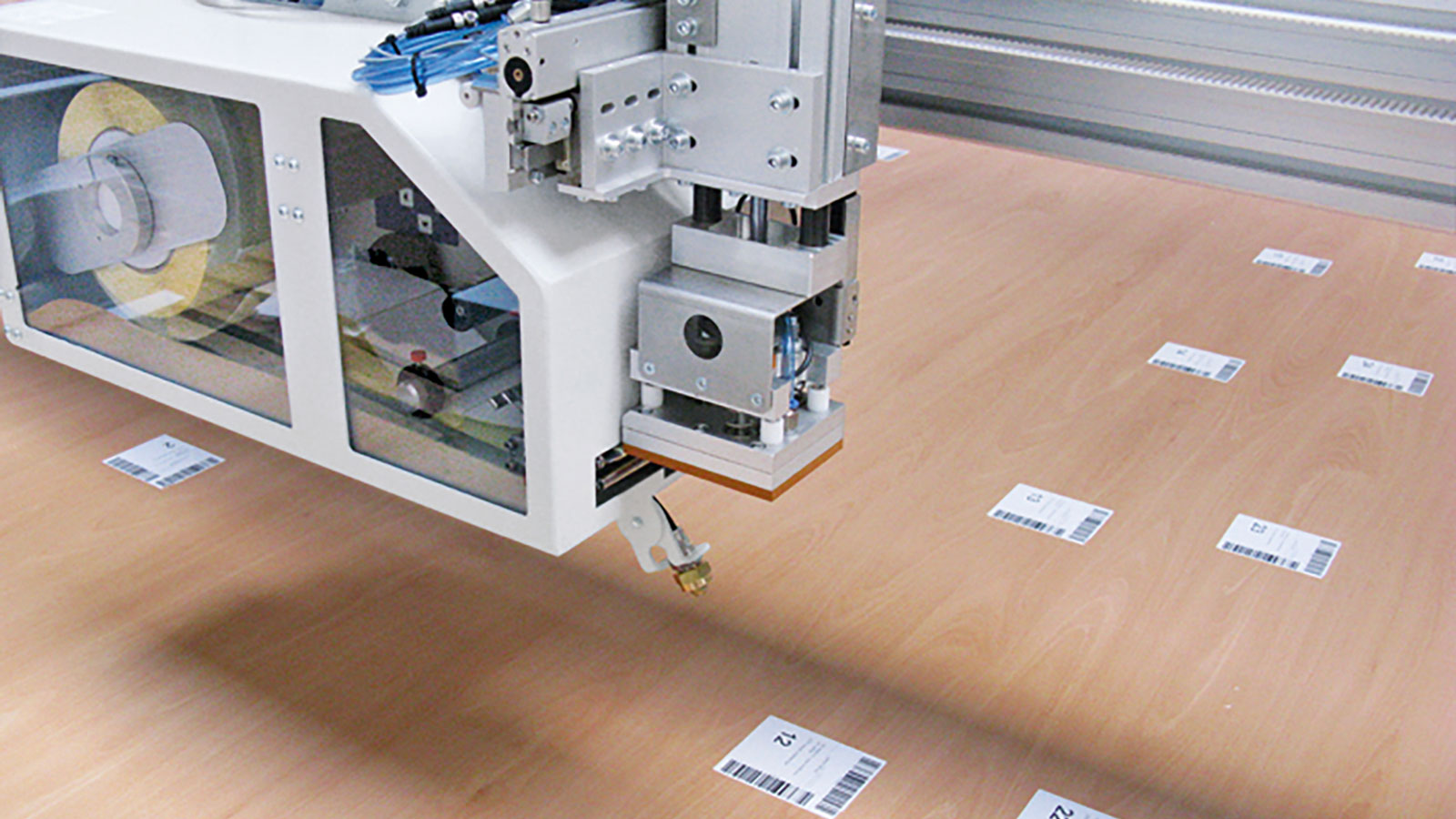

Maintenance-free lifting table for automatic feeding from the rear

-

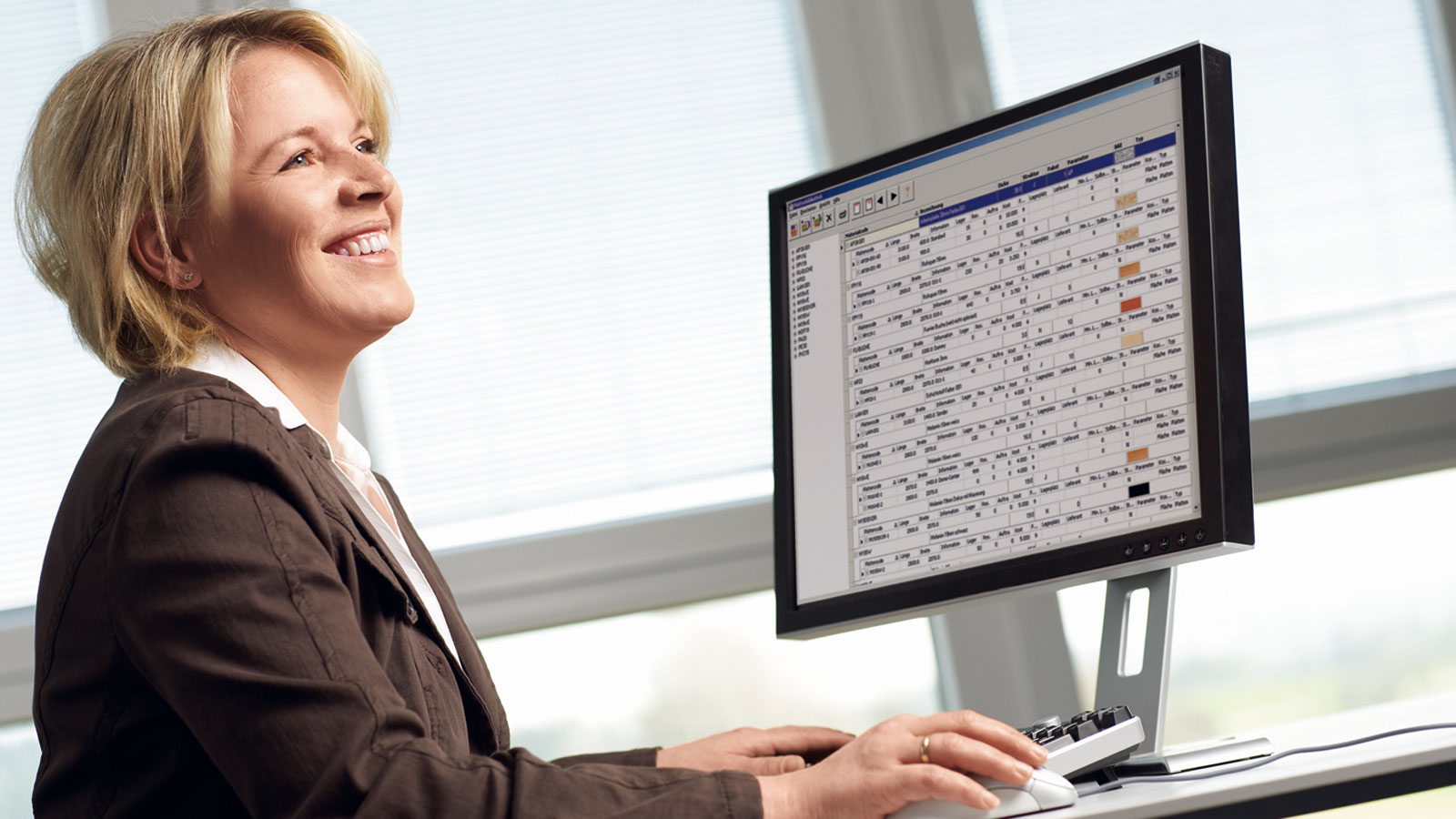

Control software CADmatic 5

– Intuitively understandable

– Full HD widescreen multi-touch monitor

– Harmonized user interface powerTouch

– The new 3D assistance graphic supports the operator and is intuitive to operate

– Ready for connection to tapio

– Graphically supported diagnostics

Technical Data

| Saw blade projection [mm] | 150 (170 as option) |

| Cutting length, cutting width [mm] | rip saw: 3,200 / 4,300 / 5,600 cross cut saw: 2,200 / 2,700 |

| Program fence speed [m/min] | Rip saw: up to 90, cross cut saw: up to 130 |

| Saw carriage speed [m/min] | up to 130 (150 as option) |

| Main saw motor [kW] | 50 Hz: 30 (47 as option) 60 Hz: 35 (54 as option) |

| Monitor | 24" full-HD multi-touch display |

| Operating software | CADmatic 5 |

(Previous product name: Panel dividing saw SAWTEQ B-500 | HKL 500)

Software

Videos

HOMAG Angular saw unit

Focus: Single boards

Brochures