Panel dividing saws SAWTEQ S-320 flexTec

Panel dividing saws SAWTEQ S-320 flexTec

Its advantages in batch size 1 production: individual cutting, fully automated production processes, unlimited recuts.

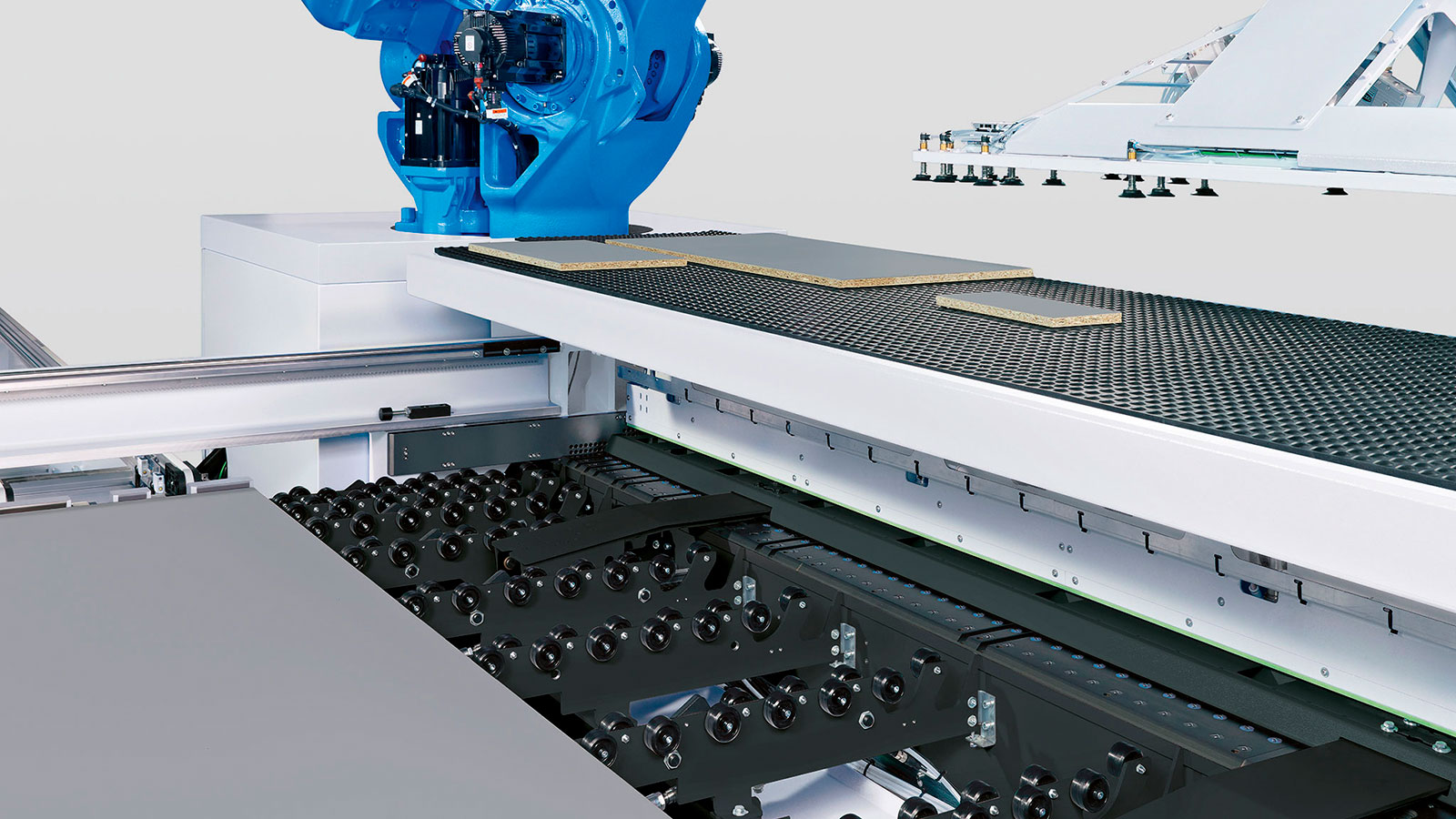

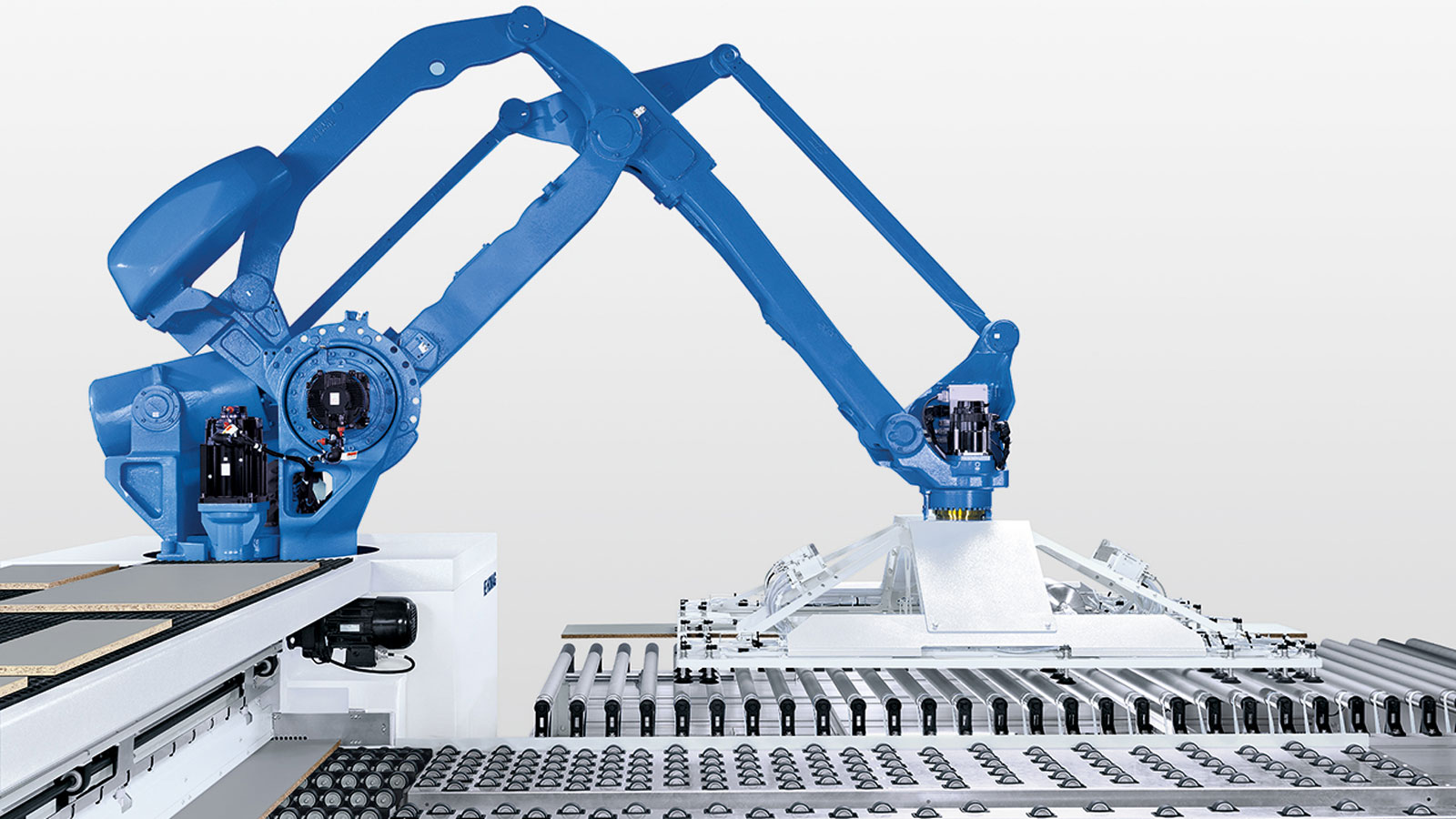

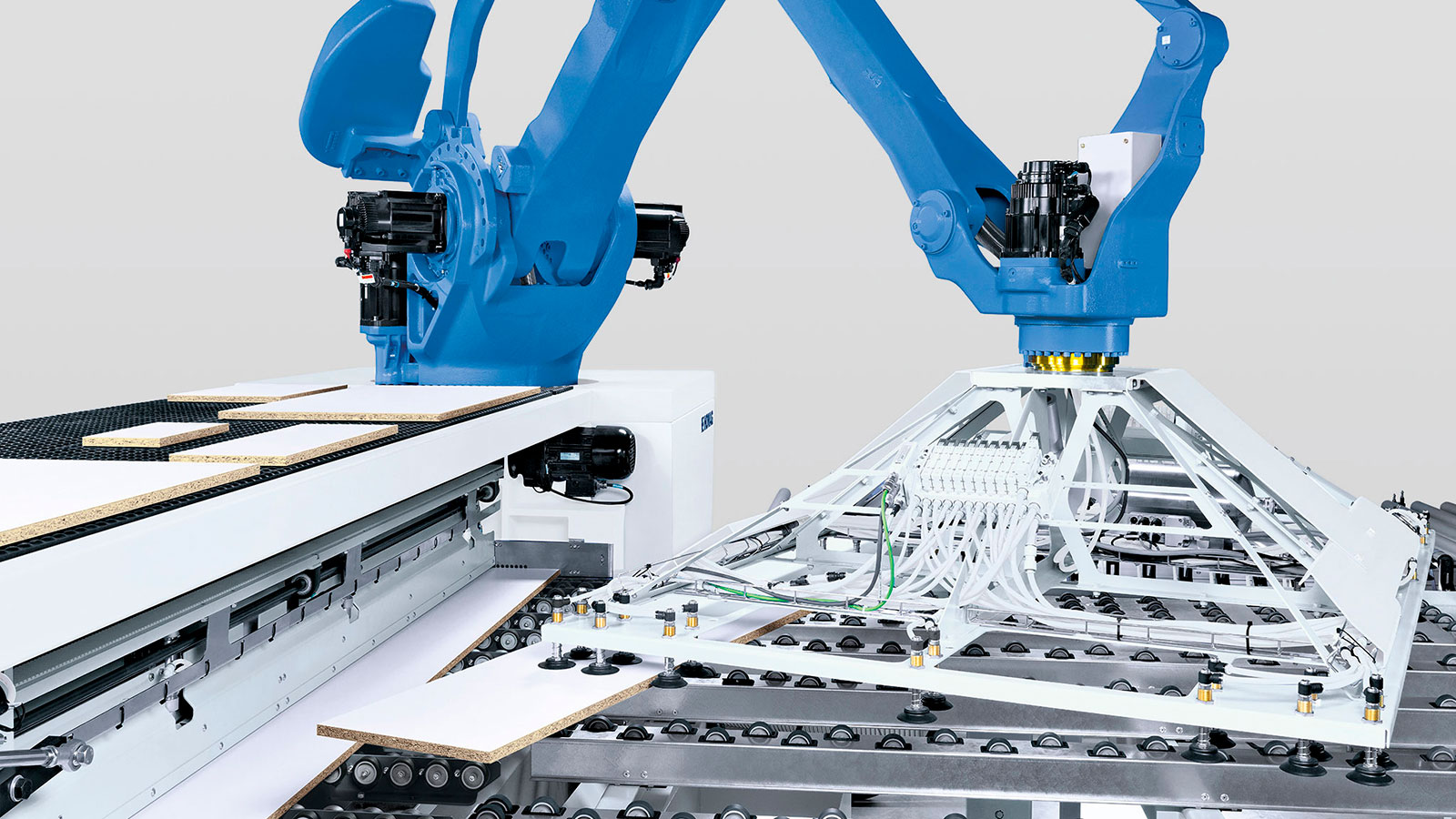

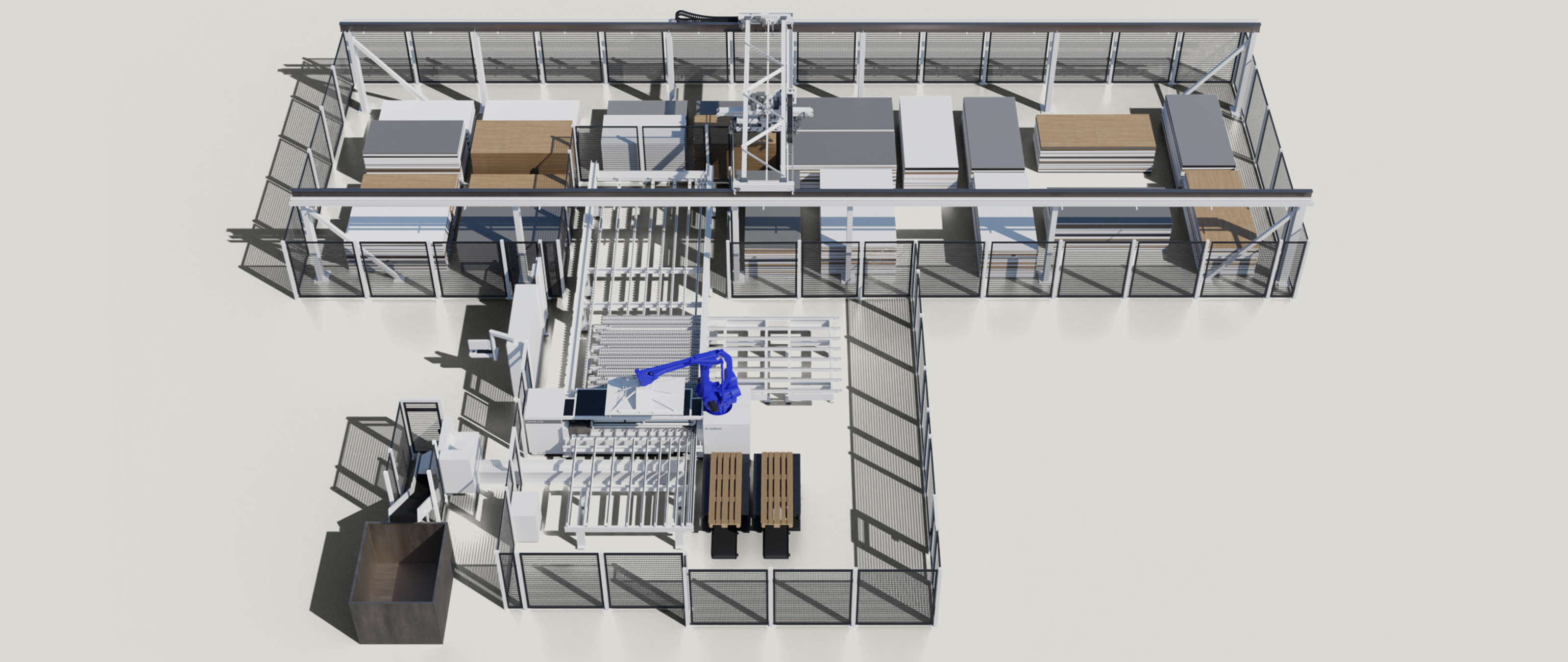

The SAWTEQ S-320 flexTec is a revolutionary cutting cell to custom cut single panels. This innovation is based on a concept that totally redefines the parts flow in order-based production and allows single panels to be custom cut under batch production conditions.

Benefits

Images

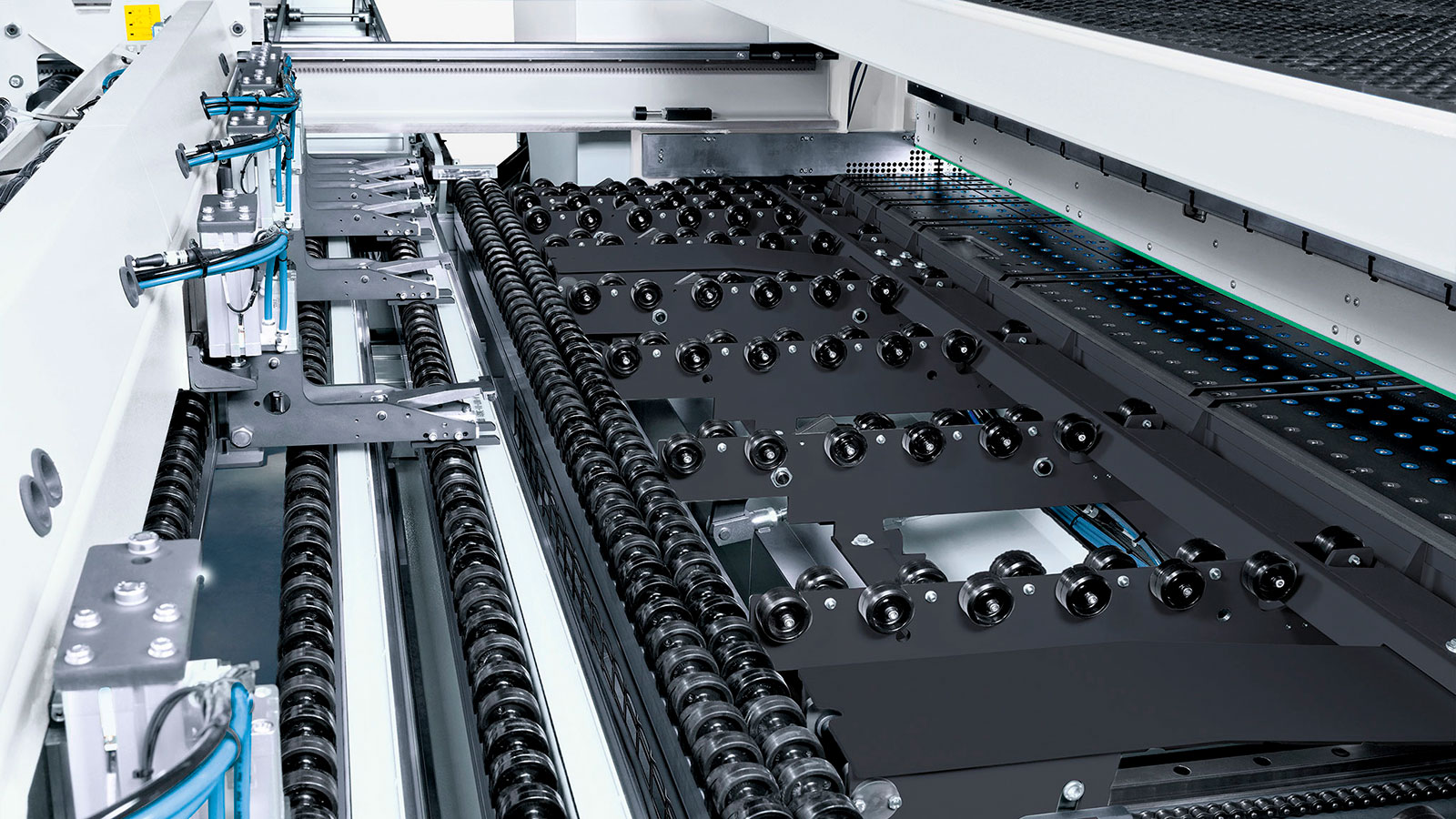

Features

-

The industrial robot undertakes all the panel handling

-

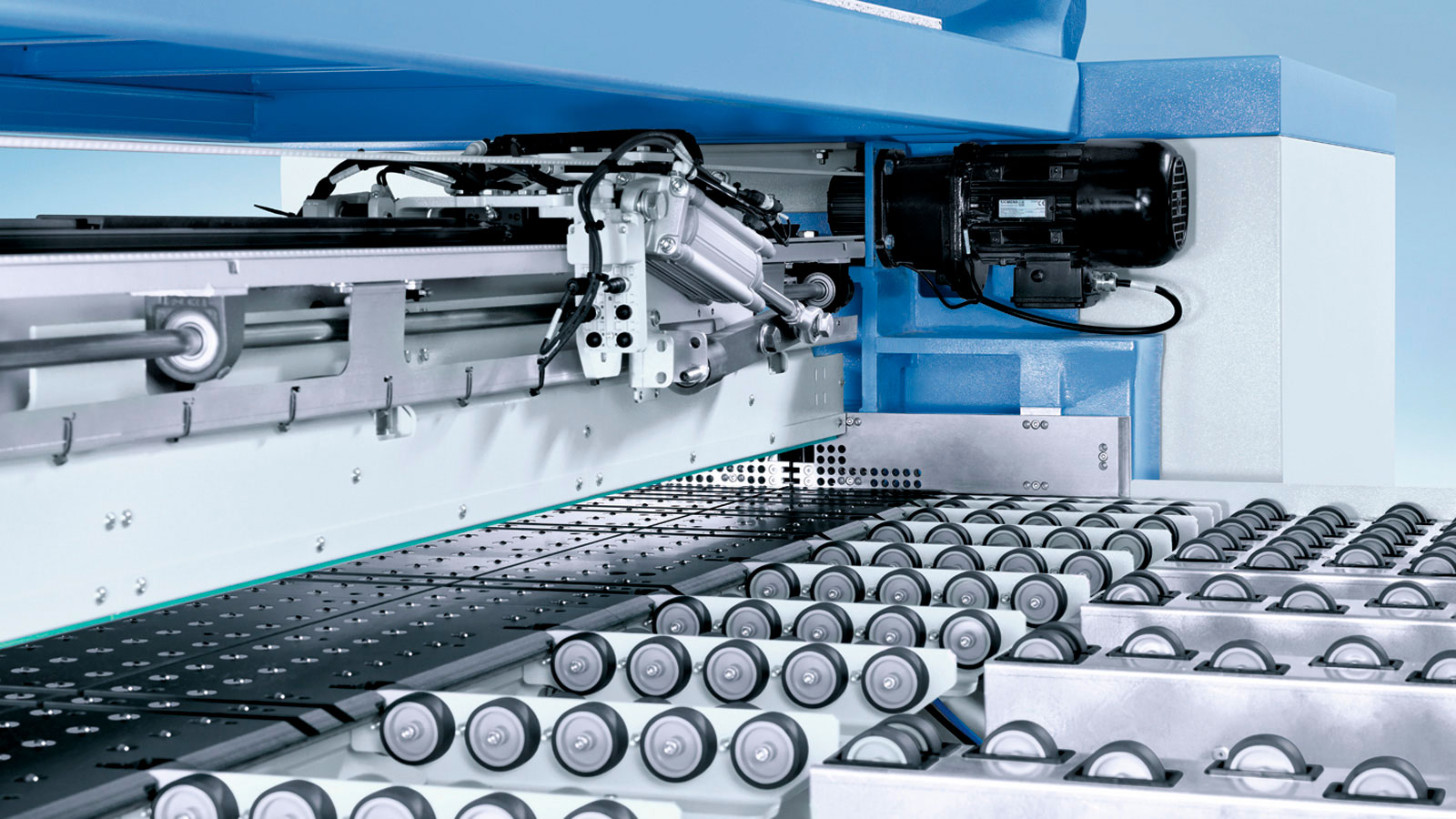

The automatic ejecting device transports all the parts away from the cutting line and back into the work area of the robot

-

Software-controlled waste flap – opens and closes in sync with the machine

-

An automatic labeling system labels all the finished parts

-

All parts leave the saw in the correct orientation

Technical Data

| Saw blade projection [mm] | 58 |

| Cutting length [mm] | 3,200 / 4,300 |

| Panel dimensions [mm] | max. 3,150 x 2,200 for 3,200 cutting length max. 4,300 x 2,200 for 4,300 cutting length |

| Part size [mm] | max. 3,150 x 1,300 / min. 240 x 80 |

| Saw carriage speed [m/min] | up to 150 |

| Program fence speed [m/min] | up to 130 |

| Main saw motor [kW] | 50 Hz: 6,5 60 Hz: 8,0 |

| Monitor | 24" full-HD multi-touch display |

| Operating software | CADmatic 5 |

(Previous product name: Panel dividing saw SAWTEQ B-320 | HPS 320 flexTec)

Brochures