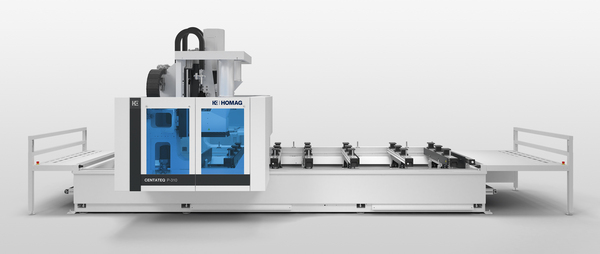

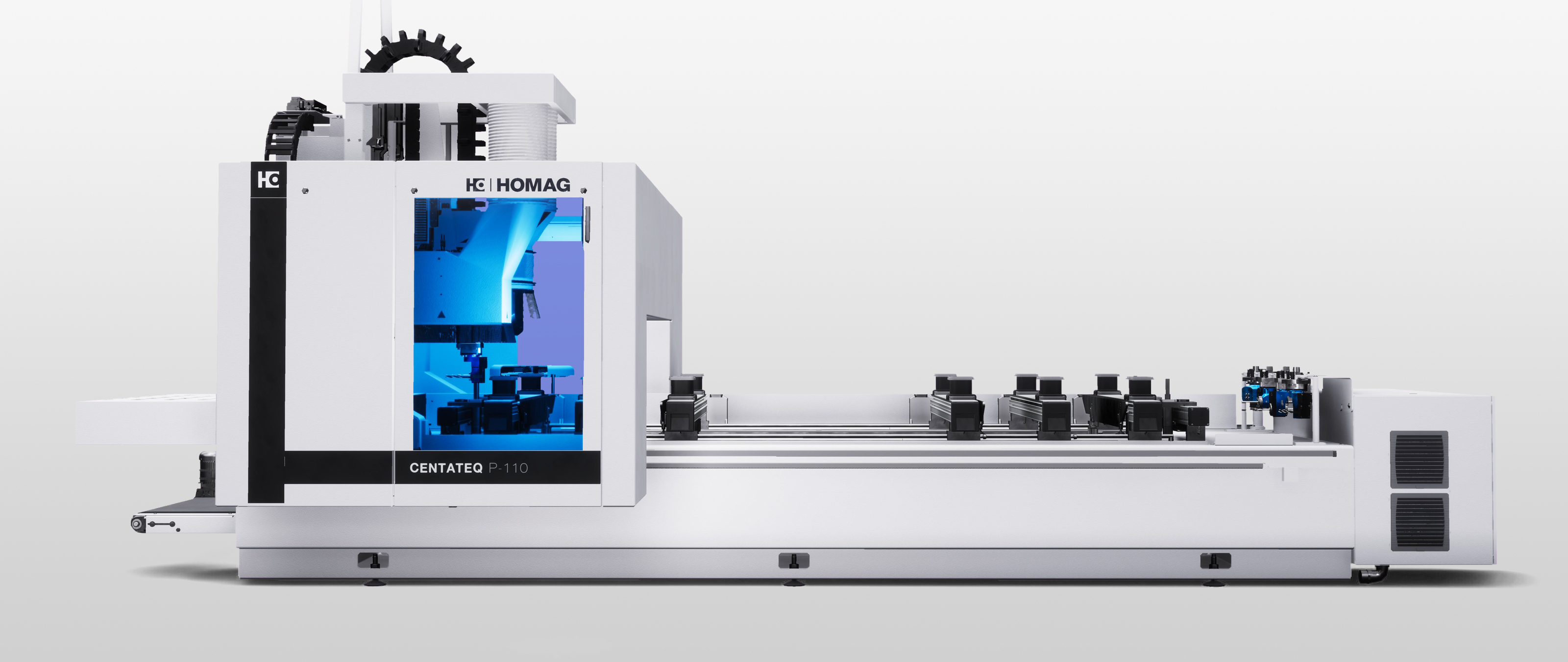

CNC Machining Centers CENTATEQ P-110

CNC Machining Centers CENTATEQ P-110

The flexible basis for CNC machining. 360° flexibility. Possibilities without limits.

Small to medium-sized carpenters and joiners benefit from the versatility and performance of this series. The machine concept is based on compact technology and a reduced footprint. Within the CENTATEQ P-110 series you will find 3-, 4- and 5-axis solutions for processing kitchen, office and solid wood furniture as well as for staircase, window and door construction.

Highlights

Convenience package: Program start, pause, release the work area or confirm after entering the scan area. Simply confirm by pressing a button directly on the portal housing.

Linear guide system: Durable thanks to cover and strip seals. High-quality protection against dust and dirt ensures lasting accuracy.

Space allocation: Simple 3D representation of machine bed, consoles, stop cylinders, suction cups and clamps on the powerTouch display. Suggestion for positioning the workpiece for machining.

Images

Features

-

Always in the right position: Effective extraction with low connected load thanks to optimized chip collection and removal. The hood can be adjusted in stages or optionally by motor and automatically adapts to the workpiece thickness.

-

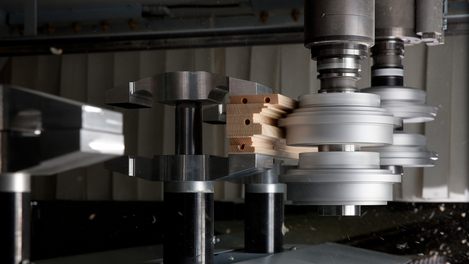

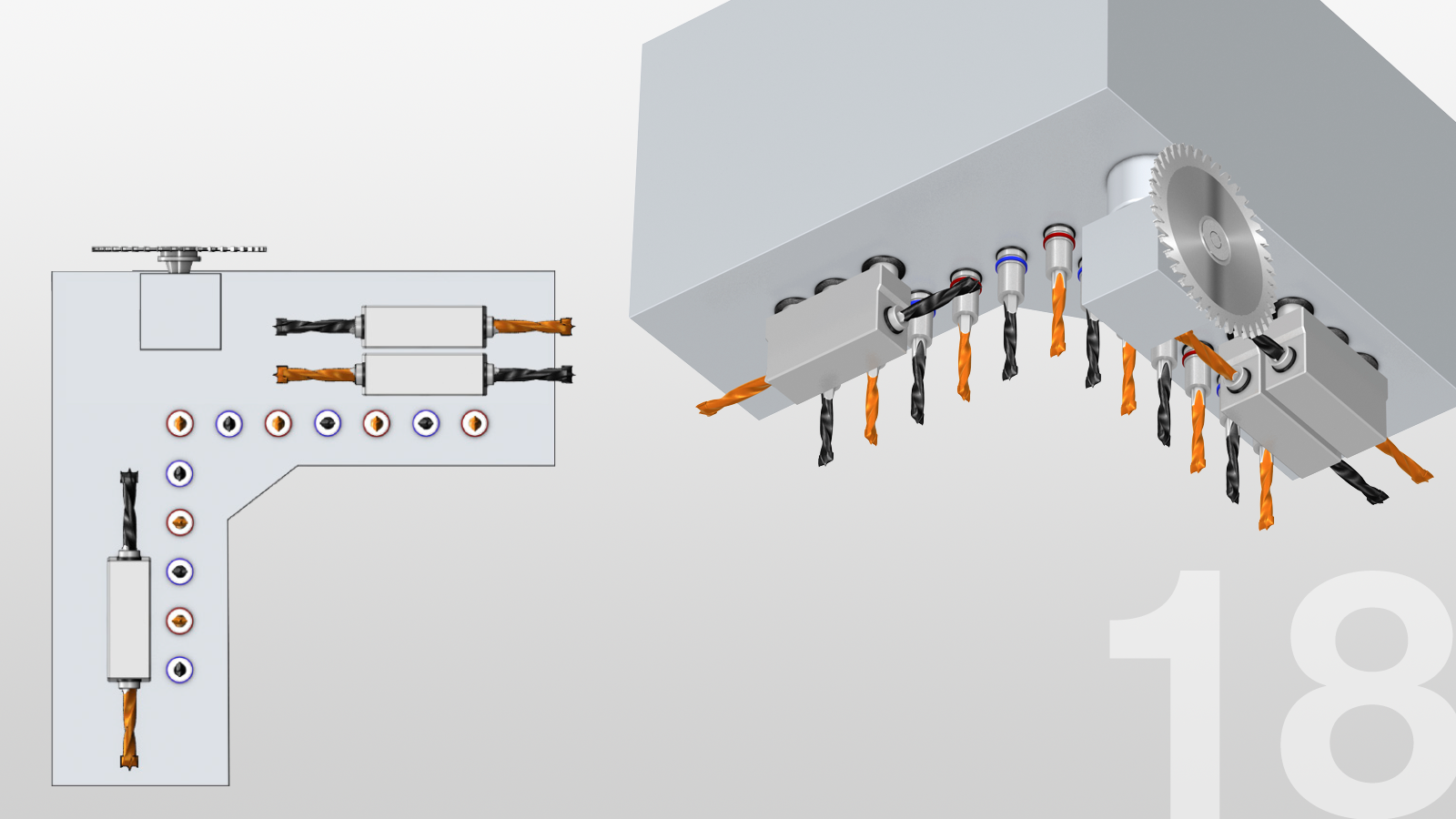

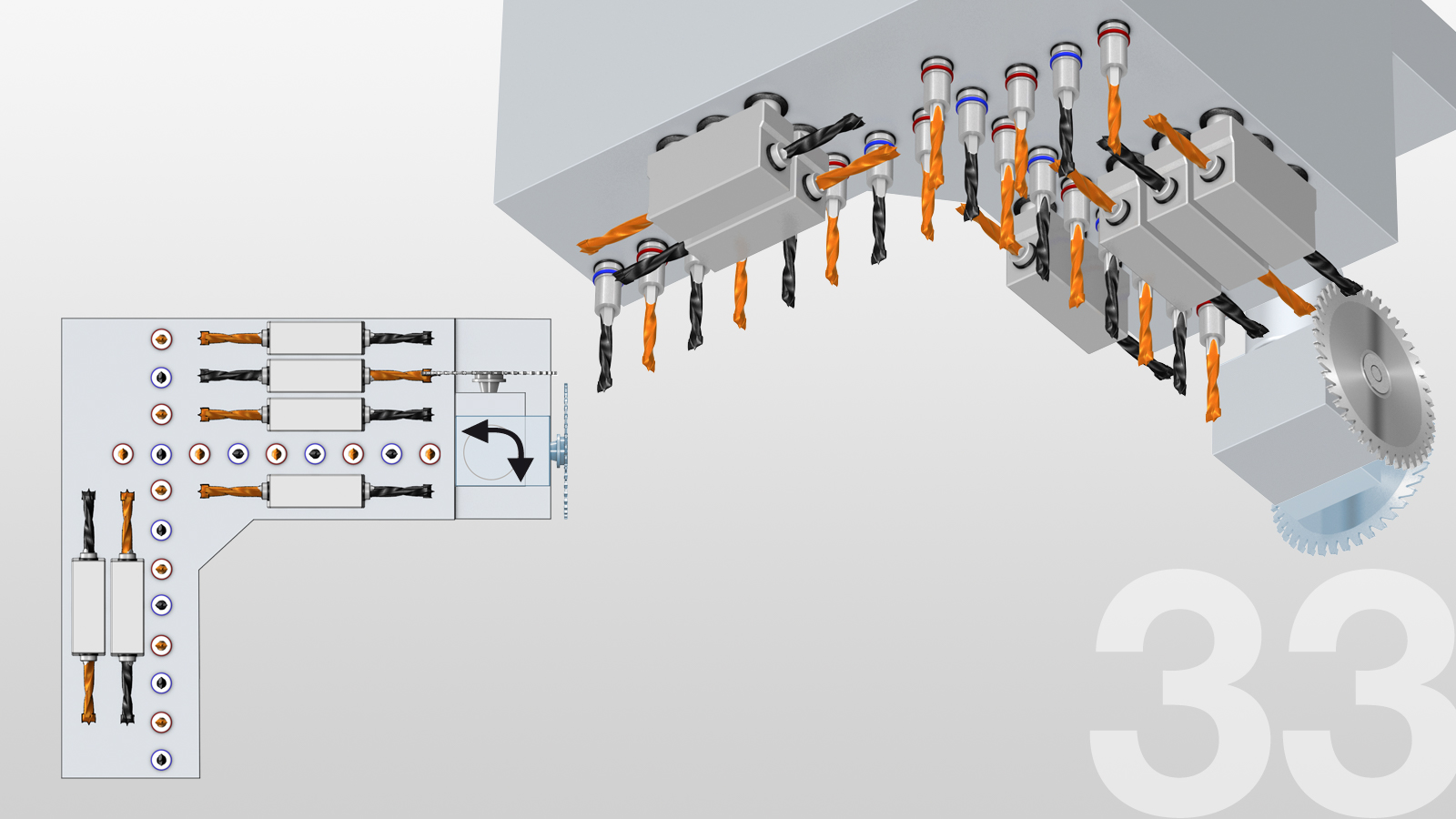

HOMAG drilling technology: High-speed drilling technology, clamping of the spindle and quick-change system for tools. Precise drilling, fast cycles, maintenance-free and durable design. Additional optional attachment units extend the machine's range of applications.

-

Spindle sensor: Milling spindles with hybrid bearings offer a long service life. An additional (optional) vibration sensor detects tool imbalances and protects the spindle from overloading, e.g. due to excessive feed rates.

-

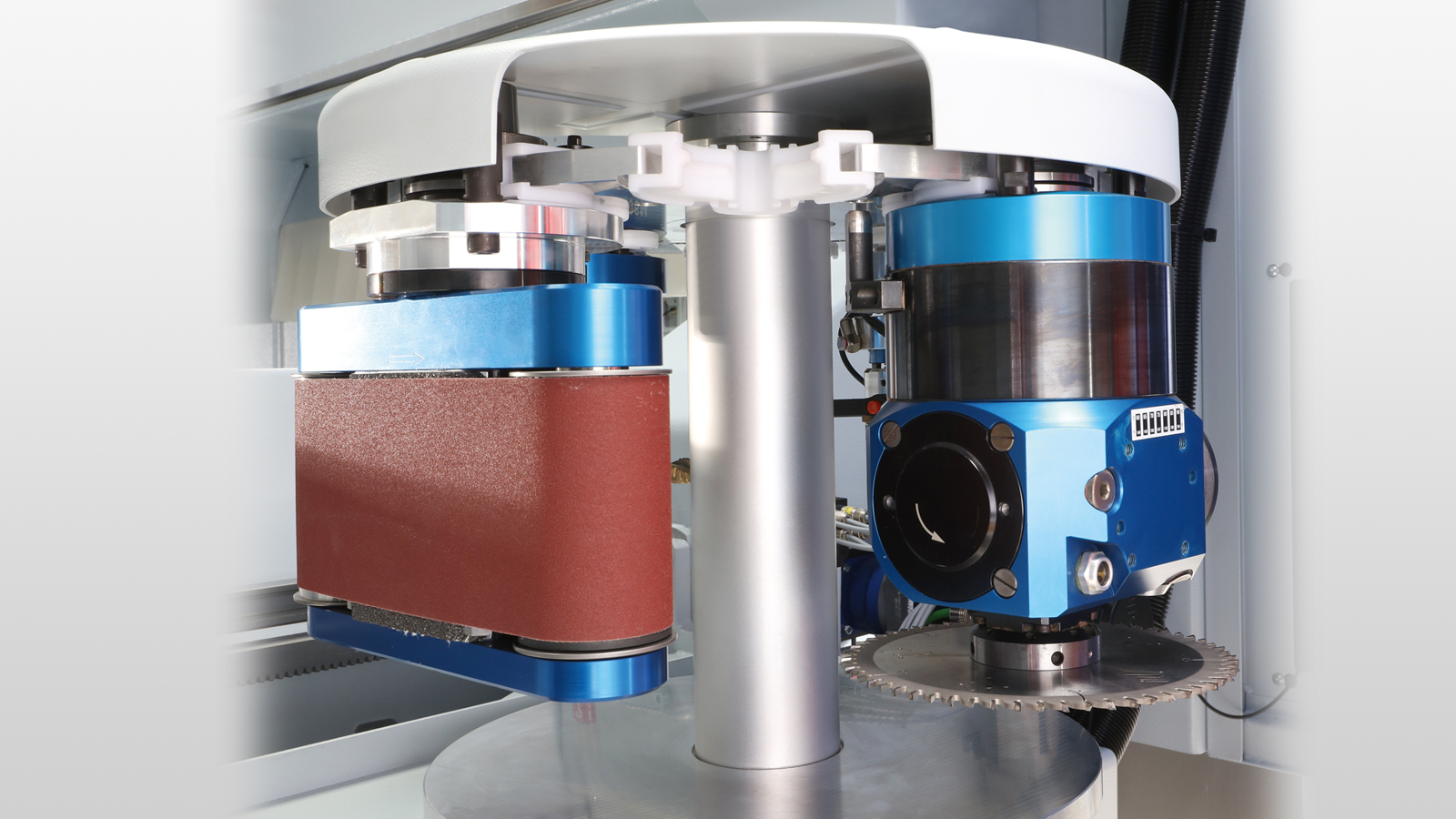

Pneumatic interface: Patented interface with 3-fold support on all C-axes and optionally on the DRIVE5CS enables the use of traced units, e.g. for precise rounding at the top and bottom, regardless of thickness tolerances.

-

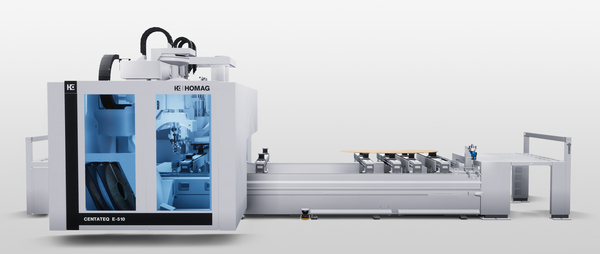

Modular unit system: The units required for the respective machining step are inserted fully automatically from the tool changing systems into the main spindle of the machines. They can be swiveled from 0 to 360° via the C-axis, for example. This gives you a great deal of flexibility and therefore plenty of scope to implement your ideas.

Start now!

Technical Data

| 1 Z-axis | 2 Z-axes | |

|---|---|---|

| Workpiece length X [mm] – Individual processing (tool length 195 mm with all aggregates) | Length M: 3,100 | |

| Workpiece length X [mm] – Alternating processing (tool length 195 mm with all aggregates) | Length M: 1,025 | |

| Workpiece length X [mm] – Individual processing (with tool diameter 25 mm) | Length M: 3,300 | |

| Workpiece width Y [mm] (with tool diameter 25 mm, rear stop) | 1,550 | 1,415 |

| Workpiece width Y [mm] (tool length 200 mm with all aggregates, rear stop) | 1,440 | 1,210 |

| Workpiece thickness Z [mm] – from console | 260 | 260 |

Some workpiece parameters may depend on the tools used. Please see the relevant brochure for further technical data.

Technical information is subject to change.

(Previous product name: Venture 113/114/115 processing centers | BMG 110 series)

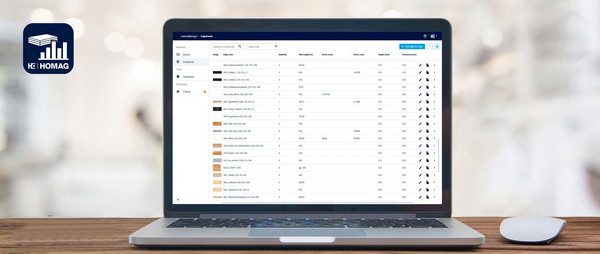

Software

Here's how your colleagues produce

You might also like

Brochures