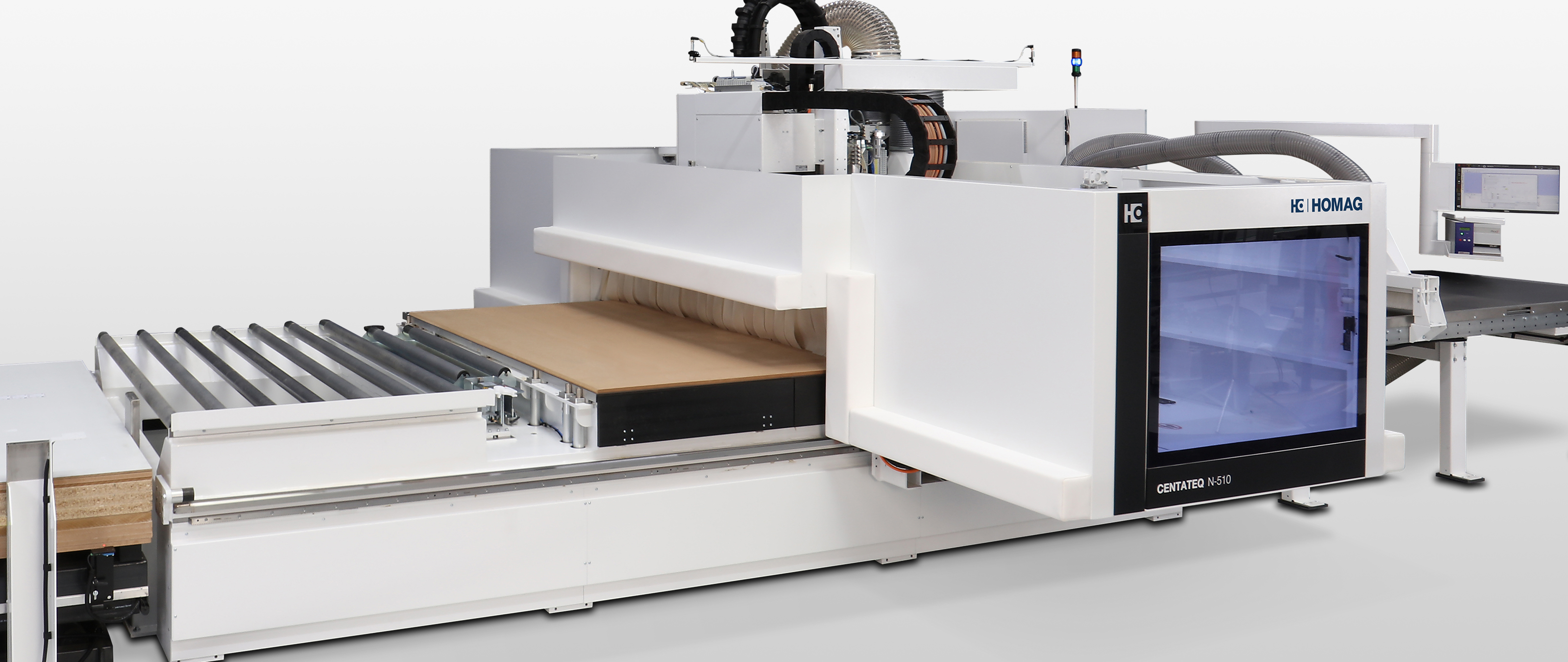

CNC-Bearbeitungszentren CENTATEQ N-510

CNC-Bearbeitungszentren CENTATEQ N-510

Die individuellen Nesting-Konzepte für die Spitzenklasse

Unsere Nestingmaschinen ermöglichen ein verschnittoptimiertes Bearbeiten und Aufteilen von plattenförmigen Werkstoffen. Der klassische Einsatzbereich liegt beim Erstellen von Korpusmöbeln, oder dem Aufteilen und Veredeln von Möbelfronten. Weitere Flexibilität bietet die Maschine bei einer Einzelteilebeabeitung auf Vakuumspannern. Automatisierungskonzepte, die einfach via Plug & Play anzuschließen sind, bieten die Möglichkeit einer nachträglichen Ergänzung der Maschine. Unterschiedlich bestückte Bohrgetriebe und Werkzeugwechsler bieten eine hohe Vielfalt.

Highlights

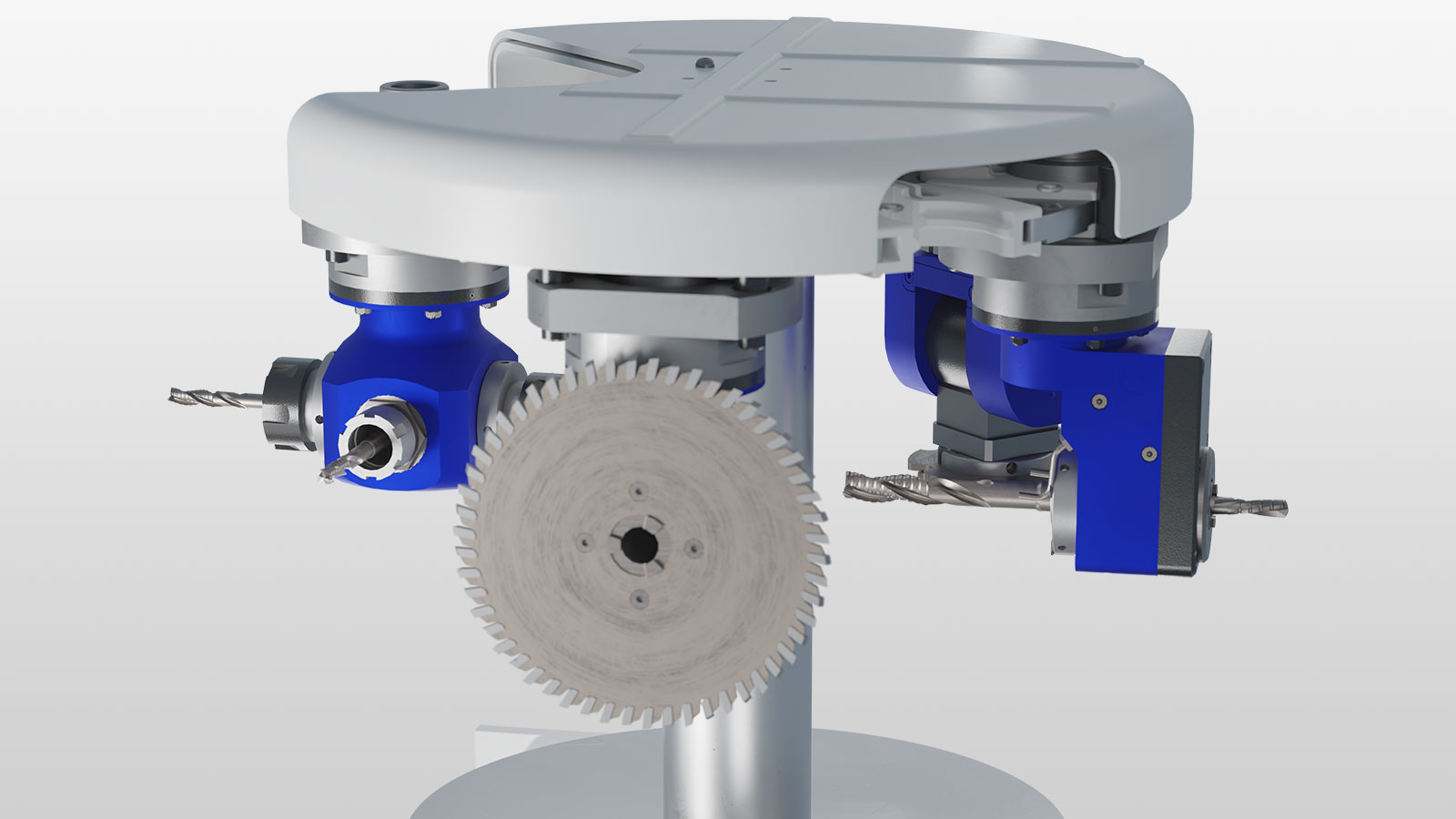

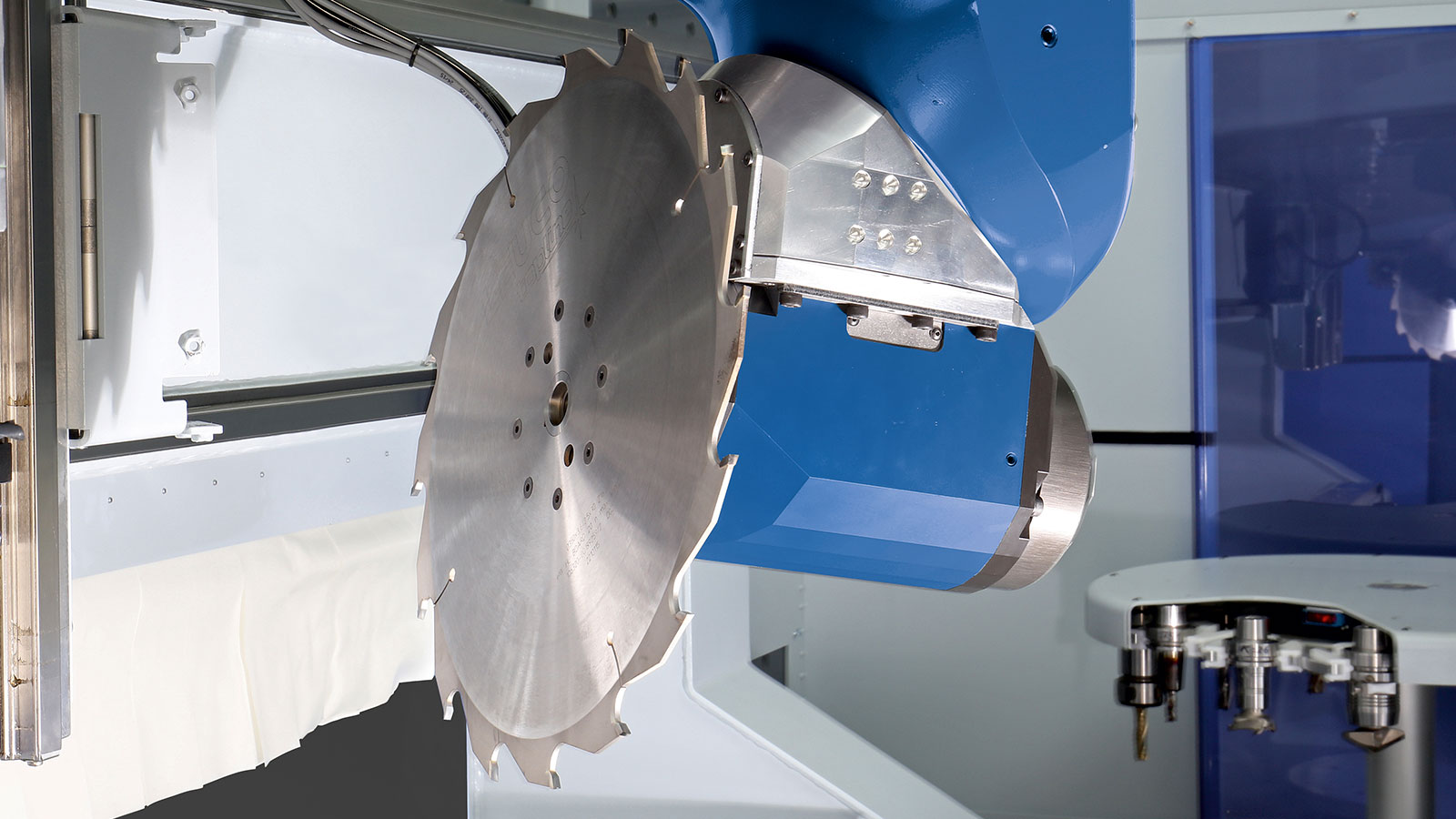

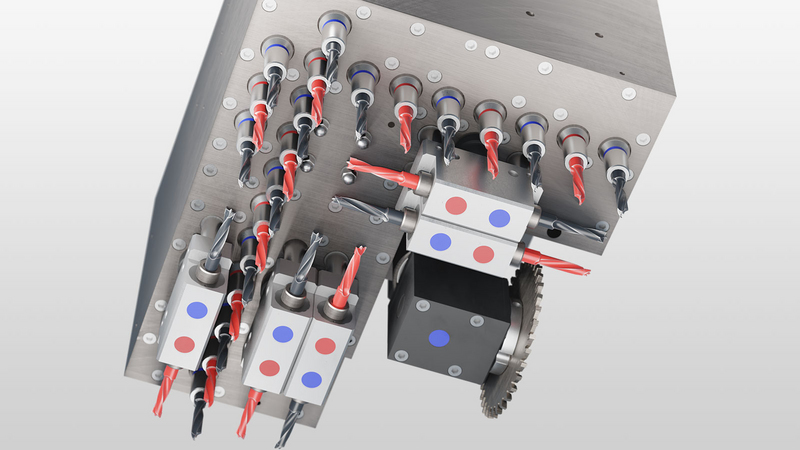

18 UNTERSCHIEDLICHE BOHRGETRIEBE - Verschiedene Kombinationen aus vertikalen und horizontalen Spindeln und Nutsägen sind möglich.

Multipositionsabsaugung für eine einfache Integration in die Produktion und reduzierte Kosten für Peripherie

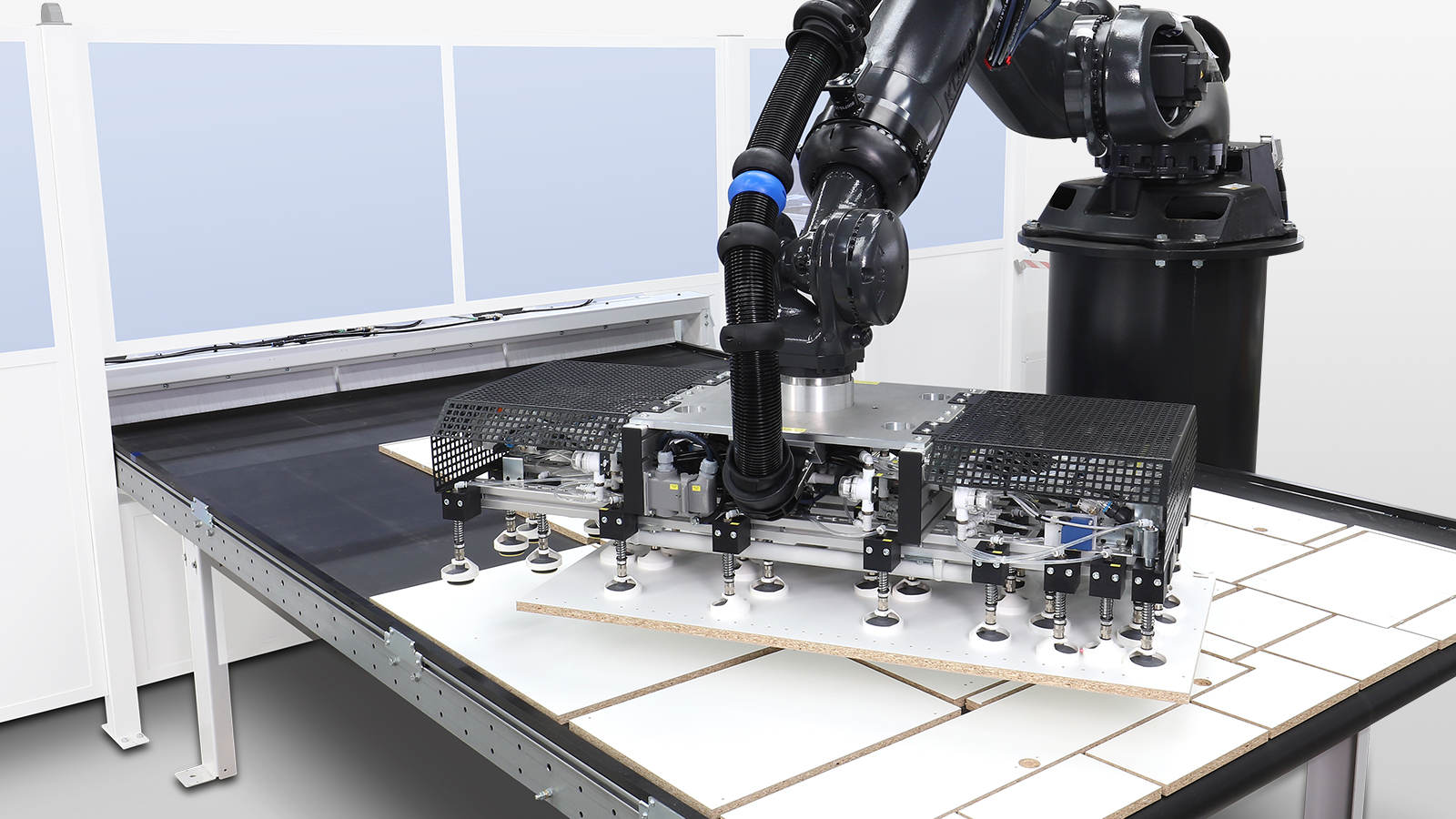

Durch unsere Plug & Play Features ermöglichen wir die sukzessive Erweiterung der Maschine von Anfang an. Ob die Werkstücke per Hand, Rollenbahn, Hubwagen oder per Lager zugeführt werden sollen – wir haben immer das passende Konzept für Ihre Anforderung.

Im Fokus des zweistufigen Sicherheitskonzeptes aus Lichtschranke und Streifenbumper steht die Interaktion und das Zusammenspiel

zwischen Maschine und dem Maschinenbediener. Die Anlage kann außerdem ohne Eingriff selbständig, schnell und mit hohen Dynamikparametern produzieren.

Bilder

Funktionen

-

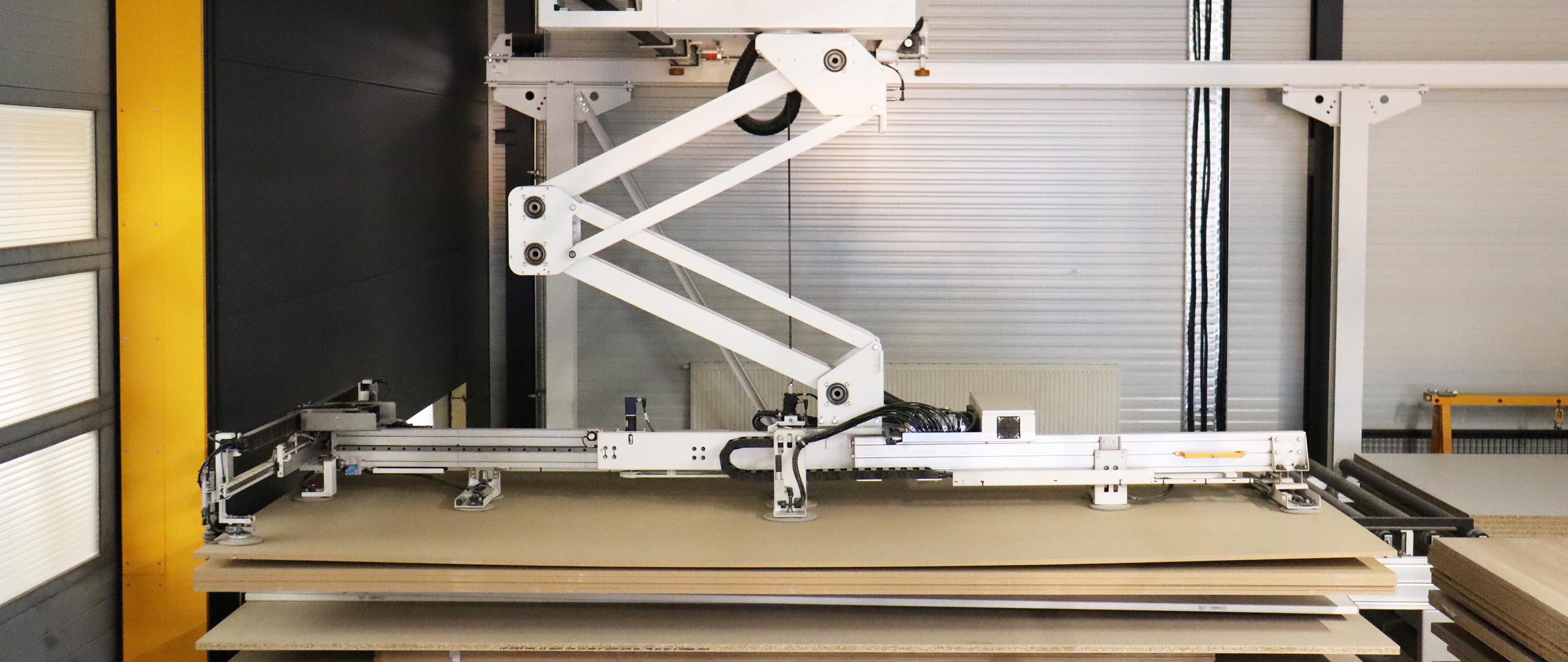

Schwere Industrie Stahl- Schweiß- Konstruktion in Fahrportalbauweise

-

Anschlaglineale vorne und hinten auf Prismenführungen

-

3-, 4-, oder 5-Achs Bearbeitung

-

Frässpindel mit Schwingungssensor für maximale Lebensdauer

-

Industrie Bohrgetriebe mit patentierter Spindelklemmung für hohe Lebensdauer und Beständigkeit

-

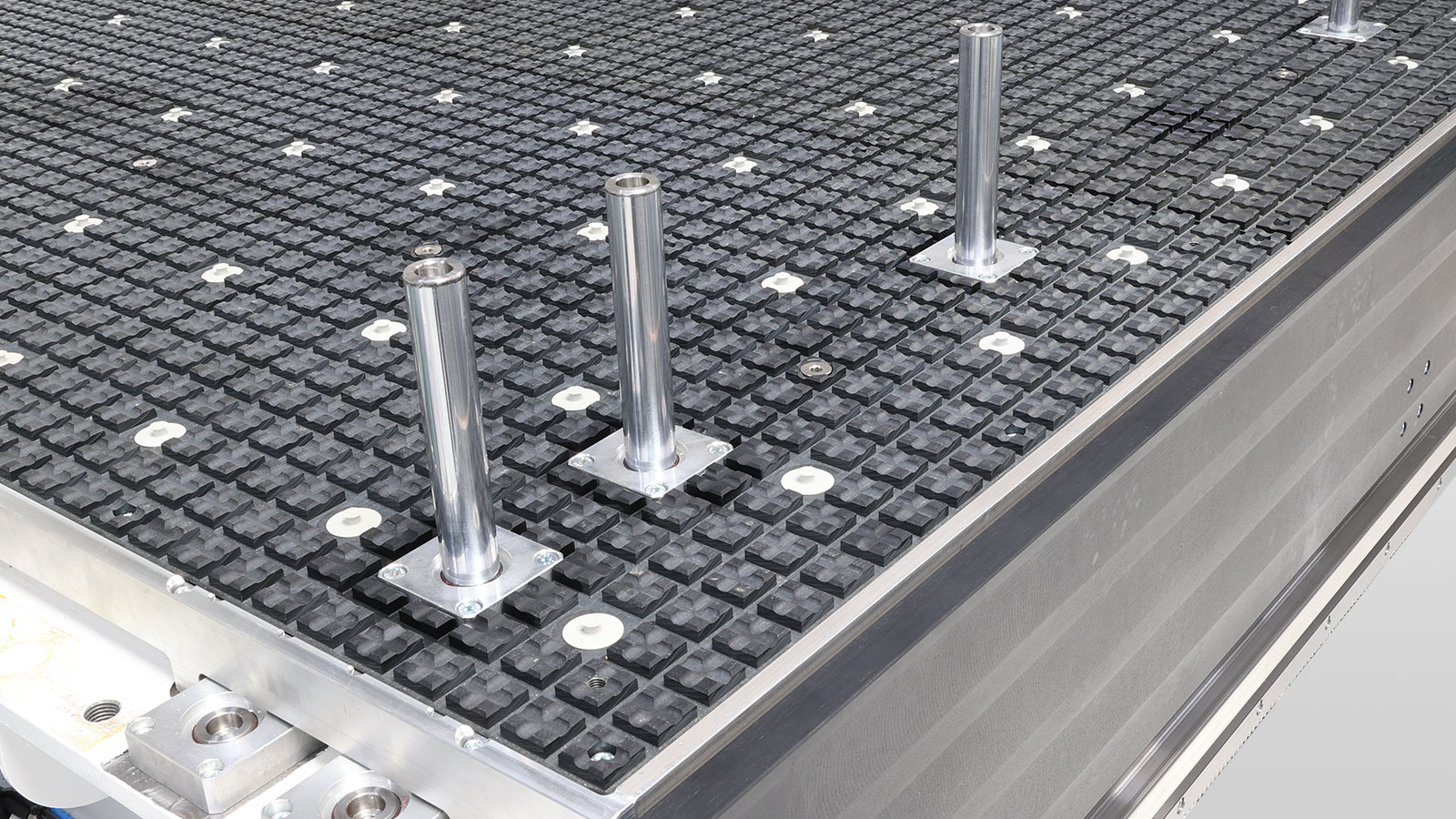

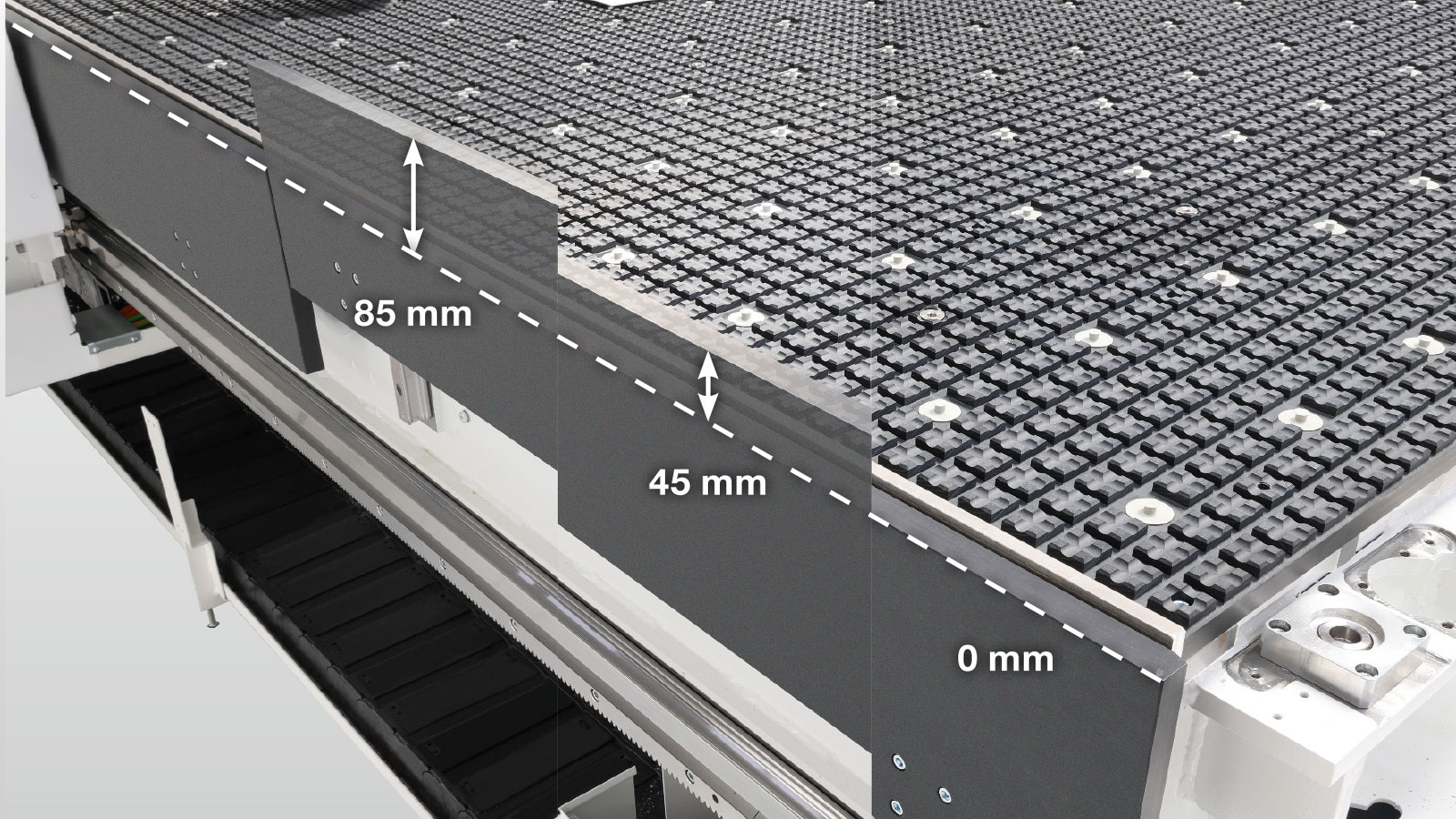

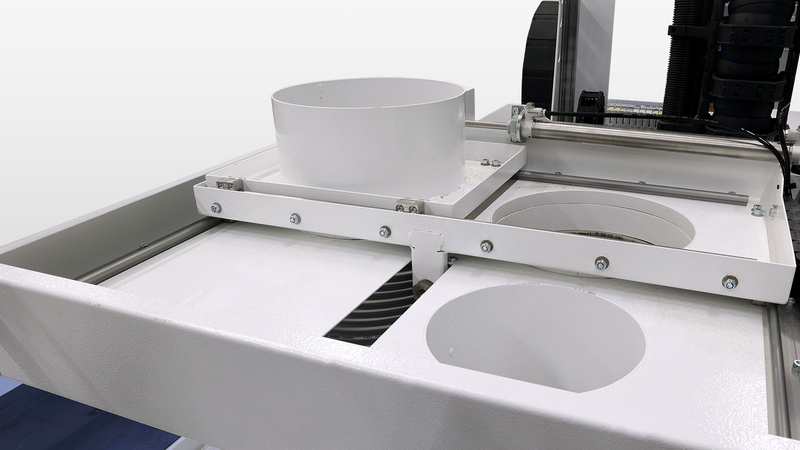

Bis zu 84 Vakuumzonen in der höchsten Ausbaustufe

-

Kleinste Feldgröße für Vakuumzonen X= 630 mm und Y = 315 mm

-

Anschlagbolzen im Tisch zum Ausrichten von Einzelteilen

-

Simultanes Ein- und Ausschieben für noch kürzere Handlingszeiten und mehr Produktivität

-

Automatisiertes Materialhandling von 3-60 mm Plattendicke

-

Offenes System mit Schnittstellen zu marktgängigen Softwarelösungen

-

Lokale und webbasierte Apps für Design, die Optimierung, Materialorganisation und Etikettieren

Software

So produzieren Ihre Kollegen

Das könnte Sie auch interessieren

Videos

HOMAG CENTATEQ N-510 | Die neue Nesting-Generation

Unsere Nestingmaschinen ermöglichen ein verschnittoptimiertes Bearbeiten und Aufteilen von plattenförmigen Werkstoffen.

Broschüren