Step-by-step: An overall concept built from single parts.

Solutions for trade businesses.

At its stand in Hall 14, HOMAG will deal with central questions faced by trade businesses, such as: What specific opportunities does digitization offer small and medium-sized businesses today? Which easy-to-use assistants and features can support carpenters/joiners in their day-to-day work? How can every business find the right building blocks for their own "workshop of the future"?

At LIGNA, HOMAG will showcase clever tools that simplify the daily working life of the user and support the working processes with minimal effort. One thing will quickly become clear: There is no need to invest in an entire system; users can instead opt for individual machines, smart hardware, software and digital assistants that communicate with each other and integrate these into their workshop. Thanks to this approach, digital solutions are also becoming increasingly relevant for trade businesses.

Visitors can experience what exactly this will be like live In Hanover – thanks to the presentation of two new, integrated cell concepts designed for carpenters and joiners:

"Your solution for digital entry"

JUST START.

At some point, almost every business faces the question of how best to get started.

The "Digital entry" workshop concept has the answer. Under this concept, HOMAG presents simple entry-level solutions that allow the user to gain transparency in their production, recognize potential for optimization and improve existing production processes. HOMAG's concept at LIGNA demonstrates an illustrative scenario. When an employee moves a job through the entire production process, they face different challenges:

- How can they access digital job information for their production easily?

- How can they use optimization software if there is already a cutting saw available?

- How can they retain an overview of all parts?

- How can they use data continuously?

HOMAG has a range of digital assistants to support the production process:

cabinetCreator (furniture configurator)

This furniture configurator allows the user to quickly and easily configure the furniture they want on their tablet or PC. As part of a step-by-step process, they can draw on a selection of pre-defined basic forms, which adapt intuitively to construction parameters entered by the user. The user can also create their own library consisting of their cabinet models. After the design phase, fixtures can be chosen based on fixture data from all common manufacturers. Each business can save their own structural rules and use these for new models. Digital data for production, such as drawings, parts lists and CNC programs, are created directly and can be exported.

The cabinetCreator is a web-based application and can therefore be used on any device with an Internet browser. This means that it can be used in the office, at the machine or even on the go – and without even having to install any software. Another major advantage is that the software is always up to date, and the business can use any enhancements automatically.

productionManager (digital job folder) & intelliDivide cutting optimization

Many businesses still use handwritten parts lists in paper form. The productionManager – the digital job folder – allows the data to be used consistently in production. It summarizes all production-related data and replaces the individual paper documents. All data from the cabinetCreator (furniture configurator) can easily be imported to the digital job folder, and can therefore be accessed via smartphone or tablet at any time. The operator then has a transparent status of all orders at their disposal and is easily able to enhance other parts or even transfer parts to intelliDivide cutting optimization. This software creates cutting patterns based on different criteria (low waste, short run time or simply material handling) as well as a parts list – regardless of the type of saw. Using the cutting assistant, productionAssist Cutting, the user can select the cutting pattern that works for them. Labels can be printed at the click of a button. As a result, every part can be clearly identified – at the same time, the label provides processing information about the edge banding machine and CNC processing center.

productionAssist Sorting (sorting assistant)

The prerequisite for sorting using this production assistant is a special sorting shelf. The user scans the barcode on the workpiece and receives directions on which shelving bay the first part of the furniture should be sorted onto. The advantage is that it is a simple, fast and secure process.

productionAssist assembly (assembly assistant)

This production assistant for assembly shows exploded and parts drawings as well as a view of the 3D drawing of the furniture. The user can find a list of all required fixtures using an overview, which also features a display of all the furniture that can already be completely assembled. Any type of information concerning the job is therefore always at the user’s fingertips.

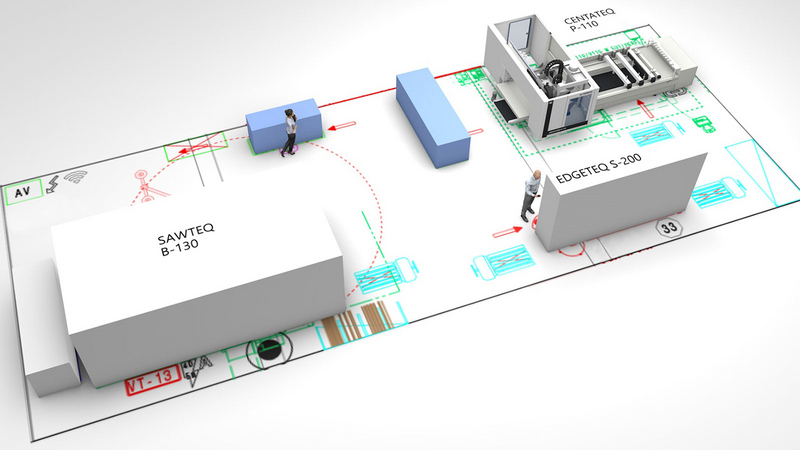

At LIGNA, HOMAG will present these new features in a workshop with the following machine technology:

Precision saw: SAWTEQ B-130

The SAWTEQ B-130 is the smallest HOMAG panel dividing saw. It costs little more than a well-equipped circular saw while providing a much more precise and efficient cutting process. Among other things, the saw is equipped with:

- CADmatic 5: The high-performance HOMAG saw control system with intuitive operating concept and clear management functions can communicate with tapio, as well as other machines and software solutions.

- Module45: With this unit, the user can also complete miter cuts on one of the panel dividing saws simultaneously.

- Labeling: The label identifies each individual part and provides important information for further processing.

Edge banding: EDGETEQ S-200 (MODEL 1130 FC)

Following LIGNA, this model from the HOMAG entry-level range can process edges up to a thickness of 6 mm and workpieces up to a thickness of 60 mm. Another new option in this series is the airTec unit. In addition to the glue application with the gluing roller (also for processing PUR), the visual zero joint can now also be created by means of hot air reactivation.

Comprehensive CNC processing: CENTATEQ P-110

Sawing, drilling, trimming: the CNC machine can be used universally for different materials, whether they are panel materials or solid wood. The machine also offers 360° clearance and all-round bumper safety technology. This allows the machine to be freely assembled and converted.

"Your solution for a networked, digital workshop"

STEP-BY-STEP ADJUSTMENT.

As part of the "Networked, digital workshop" workshop concept, HOMAG will demonstrate at LIGNA how every machine is operated by a single employee. The areas of work preparation, machinery and the bench room are organizationally separated from one another. The job data is partially available to machine users in digital form, which comes with the following challenges:

- How can digital data from different systems be used?

- Is it possible to manage the stocks of edging strips?

- How can components be quickly reordered?

- How can it be ensured that all parts for the bench room are complete?

- How can the digital data be used in the bench room?

HOMAG has a range of digital assistants to support the production process:

woodCAD|CAM design software

In woodCAD|CAM, the user can quickly and easily design furniture and jobs and create digital drawings, parts lists and CNC programs. With this software, they can rely on consistency from planning, 3D design and presentation through to construction and production of the furniture. The intuitive user interface can be used to realize individual items through to interior fittings in large quantities.

productionManager (digital job folder) & data import

All data can easily be imported from the woodCAD|CAM construction software into the digital job folder, allowing it to be called up via smartphone or tablet at any time. The operator then has a transparent status of all orders at their disposal and can quickly and flexibly enhance additional parts, such as panels.

productionAssist Edge (edging assistant)

The assistant for edge banding manages stocks of edging strips. The operator selects the parts for edging and productionAssist Edge displays the required linear meters per edging strip type. The assistant allows the edging strips to be well organized and the edge banding machine to be set up more quickly.

productionAssist Sorting (sorting assistant)

The prerequisite for sorting using this production assistant is a special sorting shelf. The user scans the barcode on the workpiece and receives directions on which shelving bay the first part of the furniture should be sorted onto. The advantage is that it is a simple, fast and secure process.

productionAssist assembly (assembly assistant)

This production assistant for assembly shows exploded and parts drawings as well as the 3D drawing of the furniture. The user can find a list of all required fixtures using an overview, which also features a display of all the furniture that can already be completely assembled. Any type of information concerning the job is therefore always at the user’s fingertips.

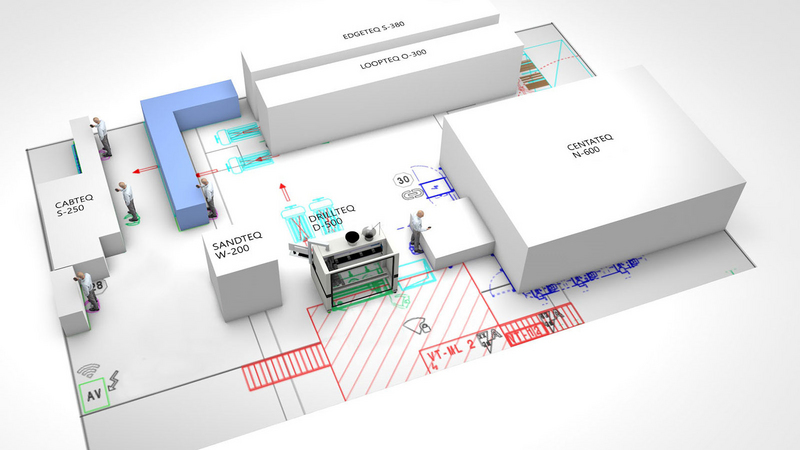

At LIGNA, HOMAG will present these new features in a workshop with the following machine technology:

Everything except edging: Nesting with the CENTATEQ N-600

The CENTATEQ N-600 nesting machine trims and drills parts—with five-axis technology, if desired—and even offers the option to insert connector fittings directly. At LIGNA, HOMAG will demonstrate this process on the Cabineo drilling unit with a new Cabineo feed system.

- New control software: With the CENTATEQ N-600, the machine control unit and printer and data handling software alike have been completely reworked. The new labeling software woodPrint 4.0 is a key component. This allows layouts for labels to be created and printed very easily.

Horizontal drilling, trimming and dowel-driving: DRILLTEQ D-500

- Processing for connector fittings: After LIGNA, the DRILLTEQ D-500 will additionally be able to carry out trimming and thus execute processes for all current connector fittings such as the Lamello Clamex, and hinges such as the Grass Tiomos. The machine can also insert a number of connector fittings directly.

- Operator assistance system intelliGuide: intelliGuide provides support with all work steps. The system uses LEDs to signal to the machine operator which work step should be performed next.

3 edge banding processes and 3 multi-step units: EDGETEQ S-380 profiLine

Perfect jointing, easy handling and full automation are the distinguishing features of the EDGETEQ S-380 profiLine.

- 3 edge banding processes: It features a new combination of the airTec unit for hot air reactivation, the EVA quick-melt pre-melter for granulate and the PUR melting unit for processing glue cartridges.

- Full automation: The multi-level technology is used on the trimmer, profile trimmer, and scraper.

- Easy handling: A LOOPTEQ return is connected for economic one-person operation and optimal handling.

Sanding machine: SANDTEQ W-200

The SANDTEQ W-220 is a compact entry-level model with high quality equipment. It has a flexible range of applications and can handle calibration, fine sanding and intermediate varnish sanding.

Pressure beam system eps®: The electronic segmented pressure beam system eps® (electronic pressure system) ensures that there is always optimum pressure from the sanding belt on all parts of a workpiece, guaranteeing a perfect sanding result.

Assembly assistant for pressing furniture bodies: CABTEQ S-250

It is easy for even inexperienced personnel to use the body press. The top roll pressure has been designed to be 20% stronger, resulting in greater rigidity. The integrated tolerance compensation ensures an even distribution of pressure. The CABTEQ S-250 enables a maximum assembly duration of approx. 1 to 2 minutes per standard body.